Industry 4.0-enabled FAE & Technical Support

King Son Convertible IFP Food-Tech Chamber product family series includes

-

• King Son Convertible IFP Aging Chiller

• King Son Convertible IFP Sub Chilller

• King Son Convertible IFP Superchiller

• King Son Convertible IFP Superchilling Thawer

• King Son Convertible IFP Lab Chamber

King Son Convertible IFP Food-Tech Chamber product family series is a new refrigeration and food preservation solution for the modern AIoT-era. It is incorporated with A7 Intelligent Foodtech Controller and designed with Constant Temperature and Humidity Multiple Points Monitoring and Servo Control Technology to research, develop and perform 3 novel next generation refrigeration technologies - King Son Constancy Precision Refrigeration Technology, Constancy IFP Chilling & Superchilling Technology that preserves and processes food in uniform conditions and environments, with temperature fluctuations ± 0.3°C and humidity fluctuations ±5%.

- Remote support technologies form the core of modern technical support. Remotely supporting products in the field is one of the earliest and most advanced utilizers of what today is commonly termed the ‘Internet of Things’.

- Definition of Internet of Things (AIoT)

The Internet of things (AIoT) is the network of physical devices, vehicles, and other items embedded with electronics, software, sensors, actuators, and network connectivity which enable these objects to collect and exchange data. Each device is uniquely identifiable through its embedded computing system but is able to interoperate within the existing Internet infrastructure. Experts estimate that the AIoT will consist of about 30 billion objects by 2020. - Technical support is one of the most central elements of customer satisfaction and loyalty. It has been demonstrated that Internet of Things-assisted troubleshooting is significantly faster. The time saved is worth its weight in customer relationships.

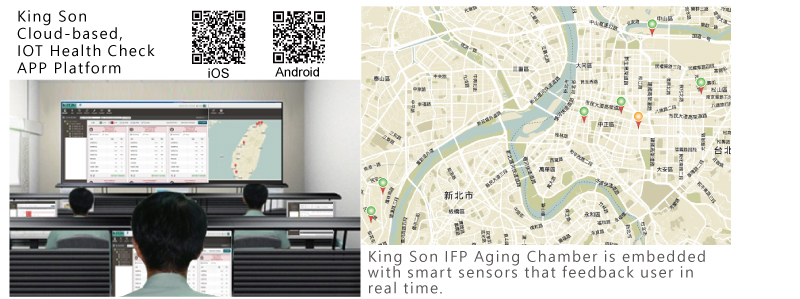

- Standard within each chamber, King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform enables remote distance services and multi-party collaboration that provides repair, maintenance and can serve as a field service platform and application.

- King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform connects multiple parties, including users, customer (owner)/IT/Service dept., dealer, supply chain stakeholders, service subcontractor, manufacturer sales representative and King Son in one platform for service and application.

- Through King Son Cloud-based AIoT Health Check App System, all stakeholders can access and monitor chamber’s running status. The App records each process’ running temperature, humidity, interface, equipment status and ambient environment.

There are four ways King Son Convertible IFP Food-Tech Chamber product family series incorporated Cloud-based AIoT Health Check App System provides customers field services

- Sustainable machinery - From reactive to proactive repairs

- Traditional field service largely adopts a break-fix approach to operations. This is to say, when a problem develops, the client suffers disruption due to a system failure such as the machine breakdown, and it is only then that a technician is called in to repair it.

- However, with the AIoT-enabled King Son Convertible IFP Food-Tech Chamber product family series, field service professionals can receive regular reports from the systems they’re monitoring thereby allowing them to react to emerging issues before they cause disruption. This results in not only more satisfied clients, but also simpler fixes rather than large-scale repairs.

- IoT will help to modernize machinery, appliances and help extend the lifetime of the chamber. IoT data can determine the best time to take a machine offline for maintenance. With a continuous maintenance plan, there is a reduction in the need for replacements. As a result, machinery is more sustainable and longer lasting.

- Reduction in errors

- The AIoT can guide field technicians to the source of the issues, as well as the best course of action. Accurate and metrics-based management will drastically reduce human error, which means an increase in success rate. Plus, a reduction in errors also means a reduction in wasted time and effort – which, then leads to cost savings for the client and the business.

- Predictive maintenance

- Field service agents will have the ability to see performance more clearly and accurately. Wear and tear, along with fracturing can be immediately reported without human involvement. The AIoT can learn from large amounts of regular operational data to detect any departures of optimal patterns. Any small changes can be flagged in an instant.

- When the chamber breaks down, the A7 FOODTECH Controller will alert the field service agent. The data records are uploaded to the cloud, which is then accessed by the field technician. When a repair issue is not addressed quickly, it can lead to greater damage in the long run. Having the ability to receive an instant data record means that problems can be remedied immediately, saving costs for extensive damage caused by unresolved problems.

- The AIoT can change how industries operate. Field service agents will have an unprecedented amount of feedback. This data can lead to even more fine-tuned insights, which improves innovation, which improves insights and so on. This continuous cycle of improvements can lead to possibilities that have yet to cross our minds.

- 100 percent uptime.

- The IoT, through cloud-based management systems, can guarantee 100 percent uptime for machines and equipment. This can become a massive differentiator in a highly competitive global market. Clients can feel more confident knowing their vendor will always have working equipment on hand to fix and/or maintain any appliance within their niche.

- The AIoT will change the speed of repairs and real-time monitoring.

- Heating and cooling units can self-report any maintenance issues. Soon, field service technicians can optimize machines via remote control – from anywhere in the world

- King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform provides multiple parties remote distance servicing and collaboration to consolidate manufacturer support from King Son and perform market local resources in one platform. This allows customers to trust and maintain confidence on King Son AIoT eco-system for FAE/customer support, repair, maintenance and after sales services.

-

King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform can optimize customer familiarity with aging process and application experiences, which contributes to optimize and fine-tune control programs and application parameters that can predict when the chamber needs maintenance services and what counter measures have to be taken in advance for improving operation.

Through King Son Cloud-based, AIoT Health Check App users can simultaneously monitor multiple chambers in the same location or different chambers in different locations.

- King Son Convertible IFP Food-Tech Chamber product family series incorporated with A7 Intelligent Foodtech Controller that is capable to program with customized AIoT data experiences and parameters on temperature, humidity and time to perform different demands of dry aging process and preservation.

- Extensible and programmable AIoT data base for laboratory scientific research and applications

Request for Customer Service, please fill out our Contact Us Form.