Pre-cooling process

Pre-cooling Process for pork carcass

Small size pork carcass pre-cooling process

According to the provisions of the livestock slaughter in large slaughterhouse, the livestock carcass after slaughter should be cut and pre-cooling treatment in slaughter house. However, with the increasing diversity of food demands, there are small amount pre-cooling process demands from small-scale specialty farms and butcher shops emerged in the market. To meet such market demands and development trend, the pre-cooling process function is also designed in King Son Convertible IFP Aging Chiller. For example, the 4 doors model in King Son Convertible IFP Aging Chiller series can provide about 80 kg carcass pre-cooling treatment capacity.

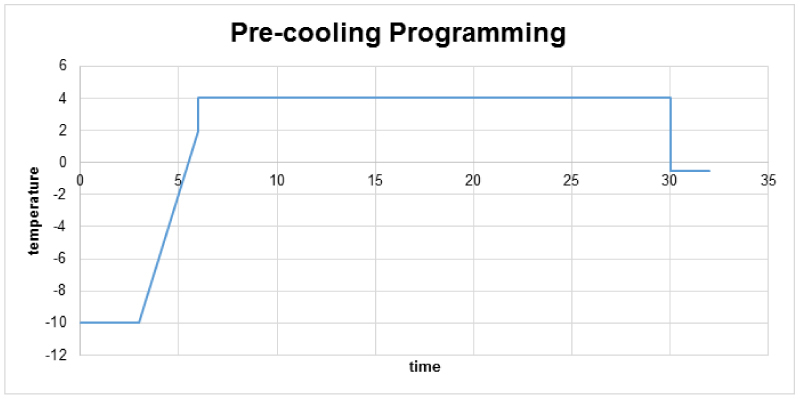

Pre-cooling Programming

-10℃/3hr → -10 to +2℃/3hr → +4℃/24hr → -0.5℃/(unlimited time)

- Pre-cooling stage: -10℃/3hr, 85% relative humidity(RH) that aims to rapidly reduce pork carcass temperature in King Son Convertible IFP Aging Chiller.

- Temperature controlled pre-cooling stage: -10 to +2℃/3hr, 85% relative humidity(RH), in which temperature is gradually increased to avoid caused carcass freezing. Rigor off (resolution of rigor) stage, +4℃/18hr, 85% relative humidity(RH).

- Sales stage, +4℃/6hr, 85% relative humidity(RH).

- Aging stage, -0.5℃/unlimited time,85% relative humidity(RH), to aging the sales remaining pork in King Son Convertible IFP Aging Chiller.

This program is designed to meet a 24-hour process from pre-cooling to rigor off. For example, slaughter pig at noon time today and start to sell pork at noon time tomorrow, therefore, there will be a rigor off process (18hrs).

Pre-cooling process

- Chamber inside cleaning, set 2 ℃ to warm up the chamber for pre-cooling process.

- Segment half carcass to primal cuts, and place the cuts, without packing and stacking, on the shelf inside the chamber. The pre-cooling capacity of the chamber is based on 70 kilograms meat for pre-cooling process simulation.

- Activates the pre-cooling program to start the pre-cooling process.

- The pre-cooling process will be completed after 24 hours. Once achieved 24 hours, the pre-cooling program stops and starts sales shelf life preservation at -0.5℃.

Remarks:

- The effects of pre-cooling depend on if the carcass keeps out of contamination. Therefore, the carcass should keep in the cold chain as much as possible, during transportation and cutting process, to reduce contamination.

- As experiments show, a warm lion pork bought from traditional market, without pre-cooling process that can only keep one night in home refrigerator; however, the chilling lion pork, which has been pre-cooling treatment in advance, that can keep 4 nights in the compartment of refrigerator.