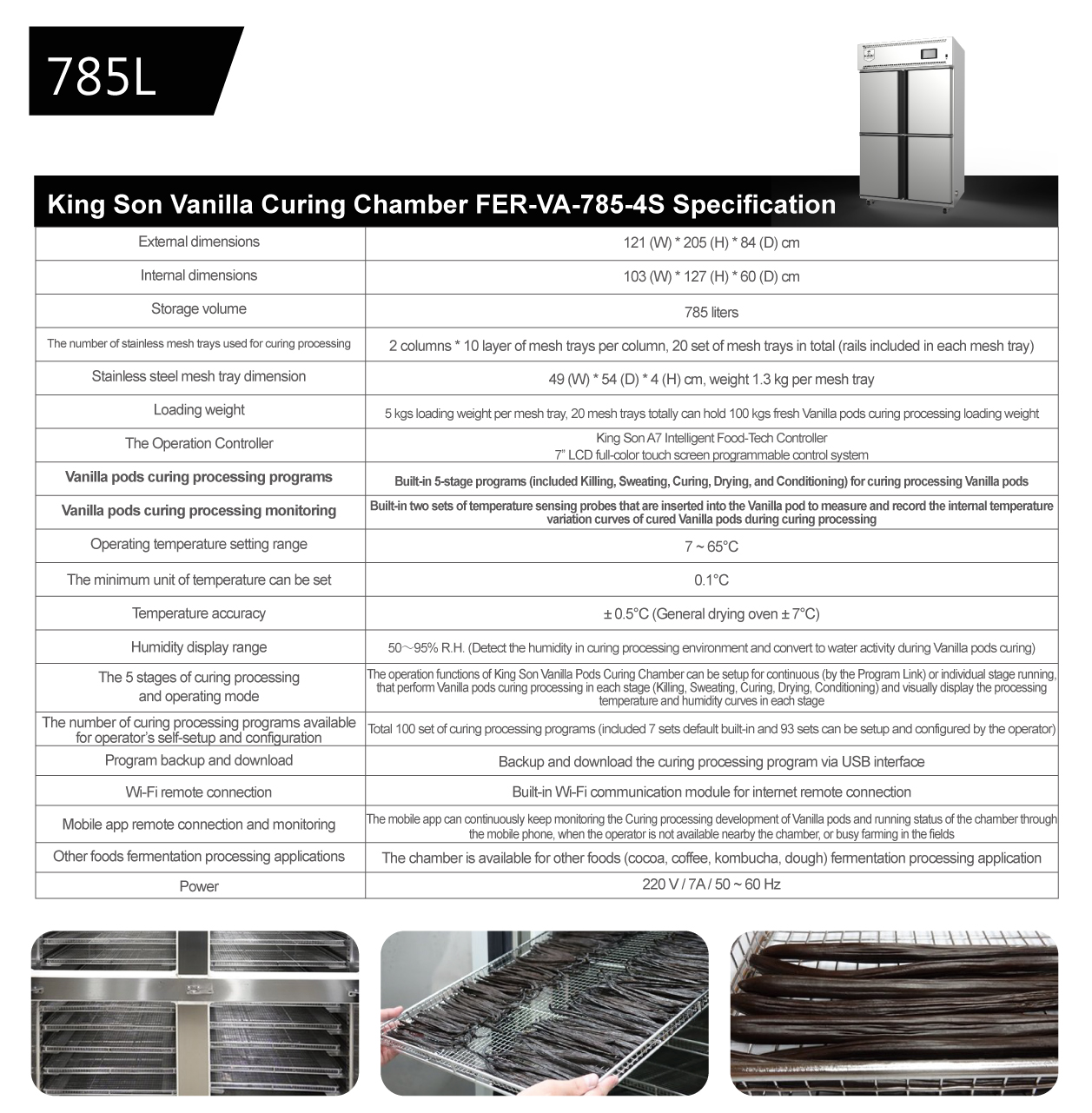

-

King Son Vanilla Curing ChamberCreate Local Terroir Aroma and Professional Craftsman Vanilla Flavor

King Son Vanilla Curing ChamberCreate Local Terroir Aroma and Professional Craftsman Vanilla Flavor

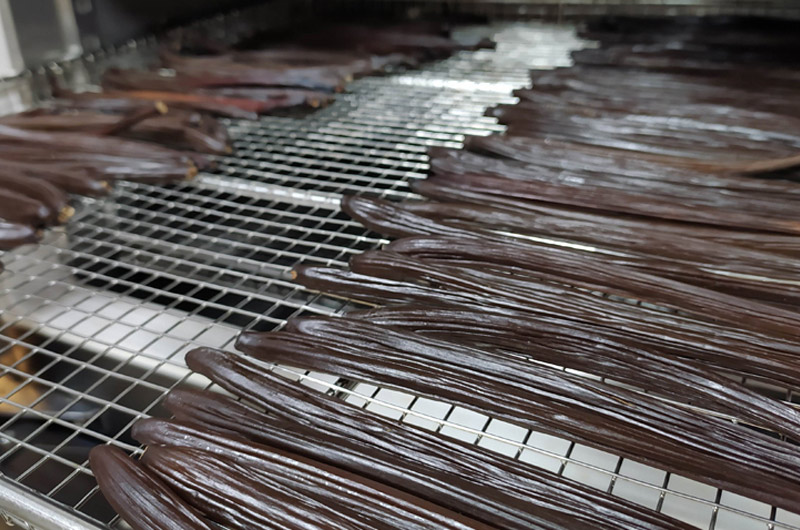

To have Vanilla pods with characteristic flavor, the most important thing is to master the temperature and humidity changes in the curing processing. King Son has designed a King Son Vanilla Curing Chamber with professional temperature and humidity control capabilities, that can simulates and generates the natural curing conditions for Vanilla pods in the chamber, [the convection heated air for Killing, precise constant temperature for Sweating & Fermentation, variable temperature to remove humidity (dehumidify) for Curing processing, day and night variable temperature for slow Drying, constant temperature for Conditioning and Ripening] that is not affected by the climate, making it easier for the craftsman to produce worldwide class high-quality Vanilla pods and its flavor.

Perform the curing processing in King Son Vanilla Curing Chamber, free the worries and impacts from rainy days, rainy season and monsoon, which avoids climate-related issues caused cured quality down, such as excessive humidity, mold, and low temperatures, etc.. The five stages of curing processing for Vanilla pods - [Killing, Sweating, Curing, Drying, Conditioning] can be done completely by one person.

The operation functions of King Son Vanilla Pods Curing Chamber can be setup for continuous (by the Program Link) or individual stage running,that perform Vanilla pods curing processing in each stage (Killing, Sweating, Curing, Drying, Conditioning) and visually display the processing temperature and humidity curves in each stage.

Built-in 5-stage programs for curing processing vanilla pods [standard feature]

Innovative technology- Convection heated air killing

By using Program Link function, easily to perform the automatic and continuous curing processing operations in the stages of Killing and Sweating.

A record of monitoring the temperature inside the Vanilla pods throughout the curing process [standard feature]

Use The Equipment, King Son Vanilla Curing Chamber for Vanilla Pods Curing Processing, Free of Climate Impacts

Built in an app for easily access and monitor the Curing processing status of Vanilla pods in real time [standard feature]

King Son Vanilla Curing Chamber

VIDEO

To Cured Vanilla Pods by the Optimum Customization-Design Know How and Experiences, with King Son Advanced Curing Processing Technology

Computer, Workstation Web-Based Application and Mobile App Oriented Cloud RD Collaboration Platform and Solution

King Son Vanilla Curing Chamber not only is a curing processing equipment, also is a Cloud Based RD Collaboration Platform that provide King Son’s food tech partners both Computer, Workstation Web-Based Application and Mobile App Oriented Solutions to develop advanced curing processing technologies and treatments for new flavors.

King Son can and would like to collaborate and co-operate with flavor food tech partners to RD customization-design curing processing technologies for new flavor profile.