Artificial freezing makes iced wine

Artificial Freezing Makes Iced Wine

Grapes for ice wine, still frozen on the vine

Ice wine (or icewine; German: Eiswein) is a type of dessert wine produced from grapes that have been frozen while still on the vine. The sugars and other dissolved solids do not freeze, but the water does, allowing for a more concentrated grape juice to develop. The grapes' must is pressed from the frozen grapes, resulting in a smaller amount of more concentrated, very sweet wine. With ice wines, the freezing happens before the fermentation, not afterwards. Unlike the grapes from which other dessert wines are made.

Natural ice wines require a hard frost (roughly -8℃/17.60℉) to occur sometime after the grapes are ripe, which means that the grapes may hang on the vine for several months. If a frost does not come quickly enough, the grapes may rot and the crop will be lost. If the frost is too severe, no juice can be extracted. Bird losses and dropped fruit will also reduce yield the longer it hands the vine. Since the fruit must be pressed while frozen, pickers often must work at night harvesting the grapes within a few hours, while cellar workers must work in unheated spaces.

5.1 Cryoconcentration for artificial iced wine

Some wine producers try to emulate the natural ice wine traits by freezing grapes or musts. Defenders of this technique in warm countries or regions like California, Australia, New Zealand, Spain, and even Argentina, say that the way in which the grape is frozen is not of importance and that the artificial process using cooling technology also allows the preservation of grapes from microbial alterations and pests. However, traditional producers say that not only the cold is necessary but that grapes mature under these aggressive conditions to develop the full aromatic complexity of a traditional ice wine.

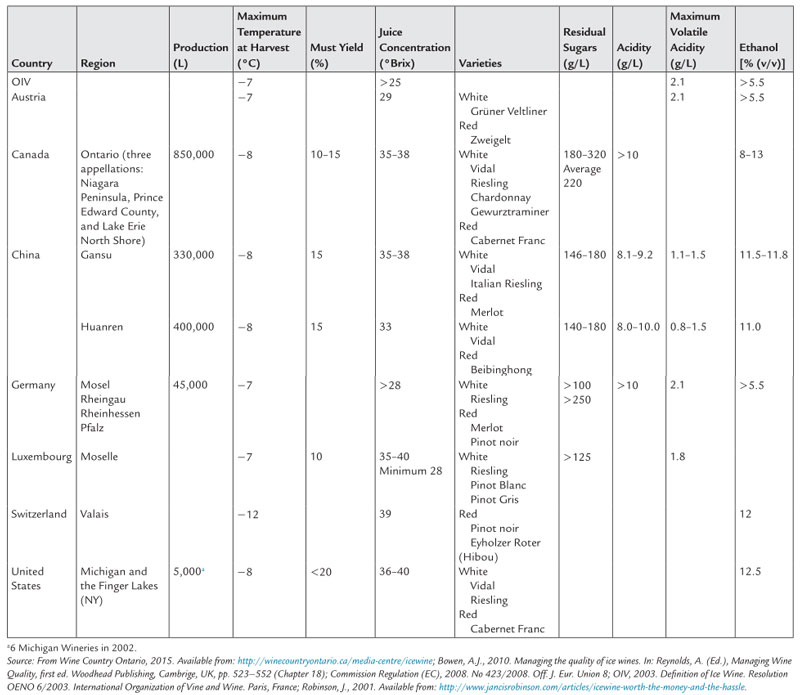

Table 10.1: Main regional regulations in ice wine production

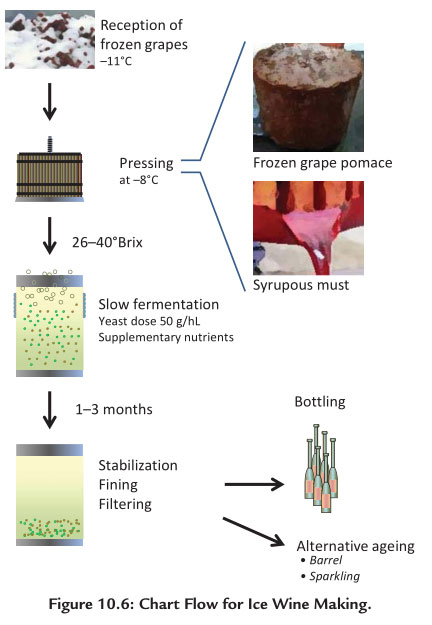

Figure 10.6 Flow chart for ice wine making

-

(Source:

-

Biotechnology of Ice Wine Production, Wang Jing, Gansu Agricultural University, Gansu, China; **Technical University of Madrid, Madrid, Spain

-

Cryoconcentration process grape must to produce artificial Iced wine

-

Harvest when the grapes are ripened, but not over ripe, 26 to 30 °Brix will do.

-

Crush the grape in a stemmer-crusher as normal to produce the grape must. Place the grape must in small plastic containers (2 to 4 gallons/7.5 to 15 L) for freezing.

-

Immediately put the grape must containers in the freezer at around

-

℃/17.60℉plus or minus a few degrees. Do not freeze the juice at temperatures that are too cold; this would make the must almost impossible to press. The object is to freeze the water, but not the juice sugar. The grape must will most likely be in the freezer for two days to freeze properly.

-

Press the grape must right out of the freezer in small batches, to keep the grape must from thawing too fast. Expect the sugar content to initially be as high as 50 °Brix. Press until the juice drops to 35 °Brix. The sugar content will decrease as the ice thaws. Stop pressing at 35 °Brix and load the next frozen batch for pressing. Continue until all fruit is pressed. The object is to extract the essence of the juice; the “nectar” which, according to VQA Ontario, must be at 35 °Brix or more to qualify as a real icewine. The finished nectar should not exceed 42 °Brix, however, or there will be real problems with excessive VA formation during fermentation.

-

It may be that all the first pressing will be in the 35 to 42 °Brix range.

-

Allow the ice wine juice to settle for 24 hours, as normal.

-

Rack off and inoculate. Lallemand W15, R2 yeasts or EC-1118 are among several recommended for icewine.

-

(Source:

-

California Icewine, Step-by-Step Procedure for Making Icewine-style Wine at Home from Grapes, Written by D. D. Smith

-

-

The specific regulations concerning the viticultural and oenological requirements for Ice wine are covered by Ontario Regulation 406/00 (and later amendments).

-

Grapes, juice or grape must intended for the production of Ice wine may be artificially refrigerated to a temperature of not less than minus 4°C.

-

Grape juice initial freezing point temperature: -1.78℃/28.80℉

-

Grape initial freezing point temperature: -1.444℃/29.4℉ (American grape type); -2.333℃/27.8℉ (European grape type)

King Son Convertible IFP Superchiller, the Cryoconcentration solution to process the grape must at the temperature between -4°C/24.80°F and -12℃/10.40℉ to produce artificial iced wine

-

King Son Convertible IFP Superchiller is a Convertible Temperature Equipment that operates at a chilled, frozen, or variable temperature condition between approximately (+6°C/42.8°F to -12°C/10.4°F).

-

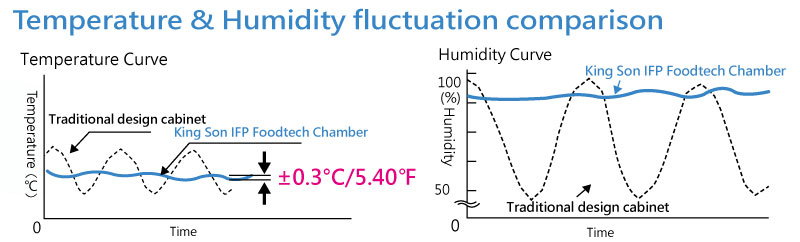

King Son Convertible IFP Superchiller is a new refrigeration and food preservation solution for the modern AIoT-era. It is incorporated with A7 Intelligent Food-Tech Controller and designed with Constant Temperature and Humidity Multiple Points Monitoring and Servo Control Technology to perform Convertible Temperature Refrigeration System between precision refrigeration and precision freezing for 6 novel next generation refrigeration technologies.

-

King Son Constancy Precision Refrigeration Technology (0°C/32.00°F to 6°C/42.80°F)

-

King Son Constancy IFP Chilling Technology (0°C/32.00°F – above Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Technology (-1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Thawing/Tempering Technology (-2°C/28.40°F to -5°C/23.00°F)

-

King Son Constancy Precision Cryoconcentration Technology (-4℃/24.80℉ to -12°C/10.4°F)

-

King Son Constancy Precision Freezing Technology (-12°C/10.40℉)

-

that preserves and processes food in uniform conditions and environments, with temperature fluctuations ±0.3°C/0.54°F and humidity fluctuations ±5%.

-

King Son Constancy Precision Cryoconcentration Technology (-4℃/24.80℉ to -12°C/10.4°F) application to make artificial Iced wine

-

Cryoconcentration has been around for a long time in the desalination of sea water. It is also used in preparation for the freeze-drying of fruit juices and coffee. Because the energy required for freeze-drying is very costly, an upstream stage is required – cryoconcentration – to concentrate flavors and produce juices with over 40% dry material content.

-

It’s the same process that produces ice wine. When grapes are frozen and then pressed, a more concentrated juice is obtained because the water, in ice form, remains with the grape pulp. To put it simply, we separate pure ice from the extracted juice.

-

(Source:

-

CRYOCONCENTRATION

-

-

-

Typical sugar level by temperature

-

-6℃/21.20℉: 29%

-

-7℃/19.40℉: 33%

-

-8℃/17.60℉: 36%

-

-9℃/15.80℉: 39%

-

-10℃/14.00℉: 43%

-

-11℃/12.20℉: 46%

-

-12℃/10.40℉: 49%

-

-13℃/8.600℉: 52%

-

-14℃/6.800℉: 56%

-

(Source:

-

All About Ice Wines - HomeBrewIt.com

-

-

-

-

-

King Son Convertible IFP Superchiller is an AIoT machine which incorporates King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform for remote distance servicing and collaboration – thus helping build new partnership opportunities through IoT eco-system.