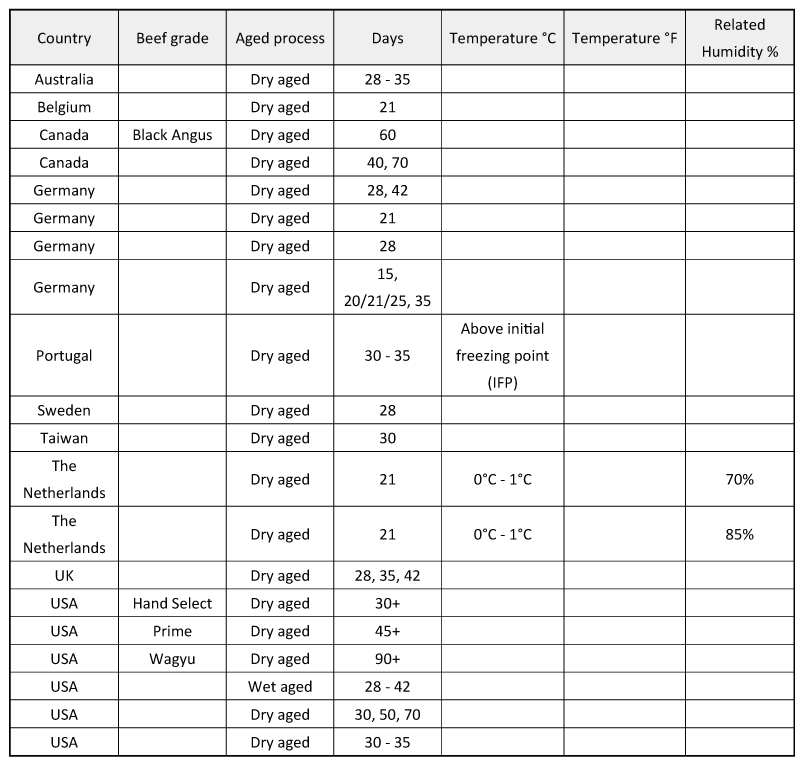

Dry aged beef process parameters reference

Dry aged beef process parameters reference

-

Effects of wet and dry ageing

- Factors affecting flavour in beef

- A literature review, with recommendations for the British beef industry on how flavour can be controlled

- Prolonging the period during which meat is held at 1ºC between butchery and retail sale, termed ageing or conditioning, is an important way to increase tenderness, especially in beef.

- It is probably the single most important factor controlling tenderness and the literature shows that it also affects flavor.

- Spanier et al. (1990 and 1997) showed that ageing results in increased concentrations of compounds in meat which contribute to flavour. These include sugars, peptides, free amino acids and fatty acids. In their 1997 study, muscles were aged in vacuum packs for up to 14 days and were then used to produce patties. These were evaluated by a 12-person trained taste panel using 1-15 point scales after grilling to a medium/well done state. As conditioning time increased, levels of descriptors associated with desirable beef flavour declined (beef, brothy, sweet) and those associated with undesirable flavours (painty, cardboard, bitter) increased. These positive and negative scores were strongly correlated showing that the changes were consistent. Changes in flavour were linked particularly with amino acids and peptides produced by proteolytic breakdown of muscle fibres.

- Lipid oxidation products were not contributors to flavours since no oxidation had occurred in the vacuum-packed beef. Jeremiah and Gibson (2003) examined different techniques for ageing beef, from carcass (dry) ageing, bone-in and bone-less vacuum packing and ageing in modified atmosphere packs. Wholesale ribs and short loins were examined and after ageing steaks were cut and grilled to 73ºC internal temperature and then evaluated on 1-9 scales.

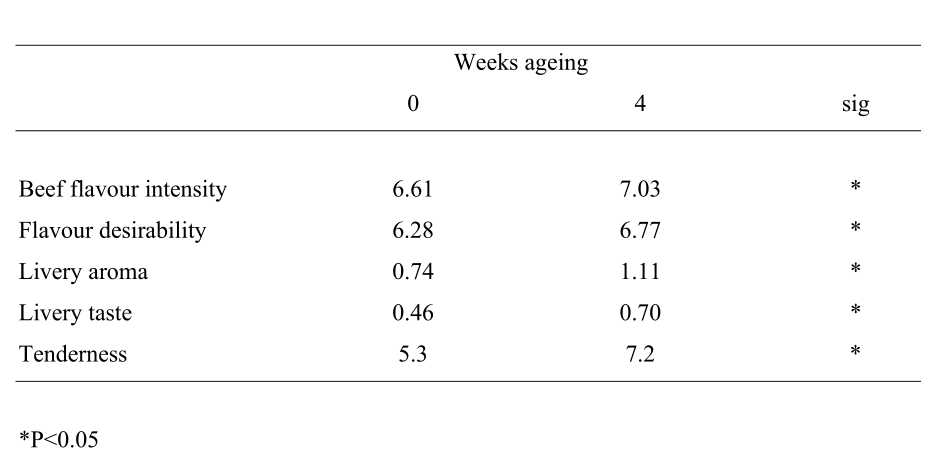

- Pooled results for all ageing treatments are in Table 11.

- Jeremiah and Gibson (2003) concluded that although some “inappropriate” flavour notes increased with ageing, the overall appreciation of flavour by the taste panel improved. Of the treatments studied, bone-in vacuum packed beef produced the highest beef flavour intensity. Gorraiz et al. (2002) also found that beef aged in vacuum packs for 7 days increased in ‘characteristic’ flavour intensity through the period. This was associated with increased concentrations of hydrocarbons detected by head space analysis. Some of these were said to be lipid oxidation products although other studies show these are low in vacuum packed meat (Spanier et al., 1997).

- Table 11. Effects of various ageing treatments on beef flavour in loin steaks (1-9 scale) Jeremiah and Gibson (2003)

-

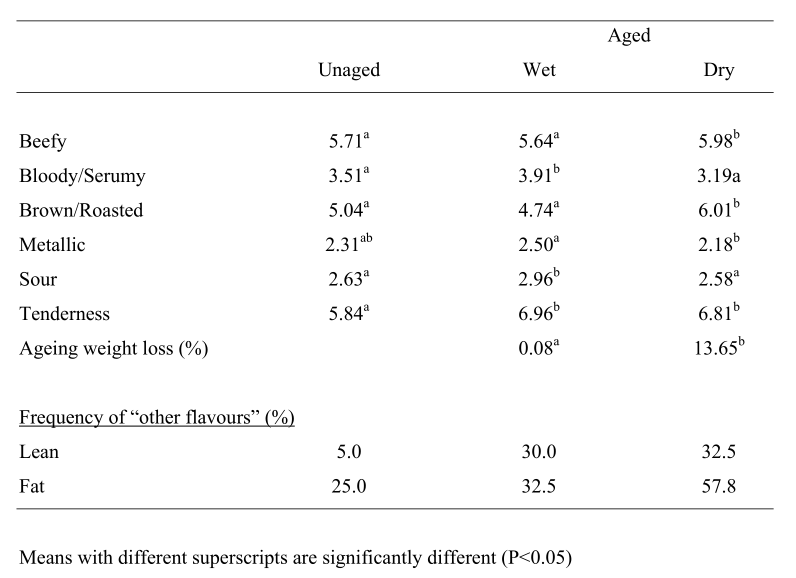

- Campbell et al. (2001) compared vacuum packed (wet) ageing with unpacked (dry) ageing and found few significant differences in flavour. However, Warren and Kastner (1992), in a comprehensive study, showed small but consistent effects in favour of dry ageing on positive flavour descriptors given by the taste panel. In this study, 8 US Choice or better striploins were vacuum-packed or not packed and aged at 3ºC for 11 days, following butchery at 3 days. Steaks were broiled on a grill to 70ºC internal temperature. Seven panellists used 1-10 scales and produced the results shown in Table 12.

- Table 12. Effects of wet and dry ageing for 11 days on flavour of loin steaks (1-10 scales) (Warren and Kastner, 1992)

- The results in Table 12 again confirm the large effect of ageing on tenderness, against which the effects on flavour seem relatively small. Descriptors associated positively with beef flavour, i.e. beefy and brown/roasted were higher in the dry-aged treatment and descriptors associated negatively with beef flavour, i.e. metallic and sour were lower. However, this generally desirable effect of dry ageing on flavour has to be set against the much larger weight loss occurring during ageing in air (0.08 versus 13.65%).

- In Britain a range of meat products launched recently by Sainsburys uses dry ageing for 21 days to increase sensory quality. The conditions under which the ageing is performed is thought to be crucial in producing a well-flavoured product. Low water activity in meat accelerates flavour formation from Maillard reactions during cooking (Mottram, 1988). It seems that an optimum balance between Maillard reaction products and lipid oxidation products has been achieved. (Source: http://beefandlamb.ahdb.org.uk )