Artificial freezing makes Iced cider

Artificial freezing makes Iced cider

Ice cider (also known as apple icewine or cidre de glace in French; sold as ice apple wine in the United States) as it’s known in its birth place of Quebec, is the cider equivalent of ice wine: a fermented beverage made from the juice of frozen apples.

Like ice wine, the apples, are left on the vine during chilly winters until they shrivel up. This produces the sweetest nectar possible. The super-concentrated juices are then pressed and fermented to add a little zing. The alcohol content usually ranges between 7% and 13% per volume.

Similar to ice wine, the use of frozen apples concentrates the natural sugars in the apples, resulting in a higher alcohol content than cider made by traditional methods.

There are two methods for making ice cider.

Like ice wine, the apples, are left on the vine during chilly winters until they shrivel up. This produces the sweetest nectar possible. The super-concentrated juices are then pressed and fermented to add a little zing. The alcohol content usually ranges between 7% and 13% per volume.

Similar to ice wine, the use of frozen apples concentrates the natural sugars in the apples, resulting in a higher alcohol content than cider made by traditional methods.

There are two methods for making ice cider.

-

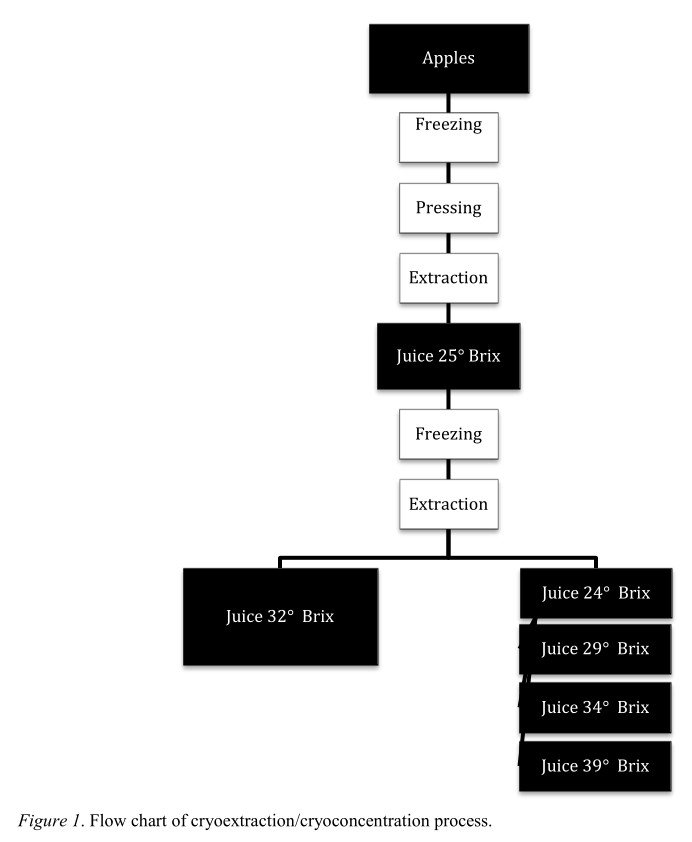

One is cryoconcentration, in which apples are pressed and juice is allowed to freeze outside during the cold Quebec winter. Water in the juice moves to the top as ice forms, and the high-sugar juice at the bottom is removed for fermentation.

-

The other, more expensive, method is cryoextraction, in which apples are left on the trees or left outside to freeze and then ground and pressed while they are frozen. Ice remains in the apple pomace, and the extracted, concentrated juice is fermented.

-

In either process, malic acid is also precipitated by the freezing process. Cold fermentation, which takes weeks or months, follows.

-

The most common method used (close to 95% of ice cider production) to produce ice cider involves harvesting the apples at maturity in autumn, keeping them fresh until they can be pressed in the winter. The resulting juice is then placed in containers outdoors during winter for approximately 6 months. Slowly, the water freezes and the sugar separates, and the must is harvested by gravity as the ice crystals rest on the surface due to their lower density.

-

Certain producers do a second cryoconcentration to increase the initial level of sugar, before fermentation. After that, at the lowest the temperature, the harvested must is fermented in vats for six to seven months before being bottled. This method gives the producer much greater control and involvement over the production process.

-

"Cider ice" drinks produced by the fermentation of apple juice, which must have a concentration of sugar before fermentation made solely by the natural cold of at least 30 Brix and whose product has a residual sugar content of at least 130 grams per liter. Finally, the alcohol will be obtained over 7% and less than 13% alcohol by volume.

-

Flow chart of cryoextraction/cryoconcentration process

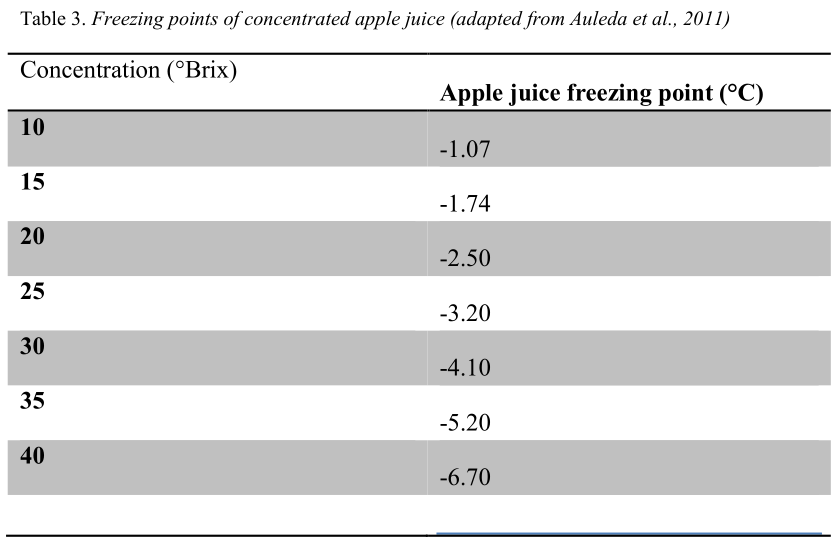

Concentrations at apple juice freezing point

-

The freezing point of apple juice at different concentrations was determined by Auleda et al. (2011). A juice with 40 °Brix will freeze at -6.7°C/19.94°F, thus at least this temperature would need to be reached in order to concentrate it to this extent.

-

The use of artificial cold in the production of ice cider is permitted only for purposes of malic precipitation, provided the temperature is not lower than -4℃/24.80℉.

-

Apple juice, initial freezing point temperature: -1.44℃/29.41℉

-

Apple juice concentrate, initial freezing point temperature: -11.55℃/11.21℉

-

(Source:

-

Ice cider product development–Effects of concentration, yeast strains and processing conditions on biochemical and sensory quality traits, Lisa Åkerman

-

-

Artificial freezing iced cider

-

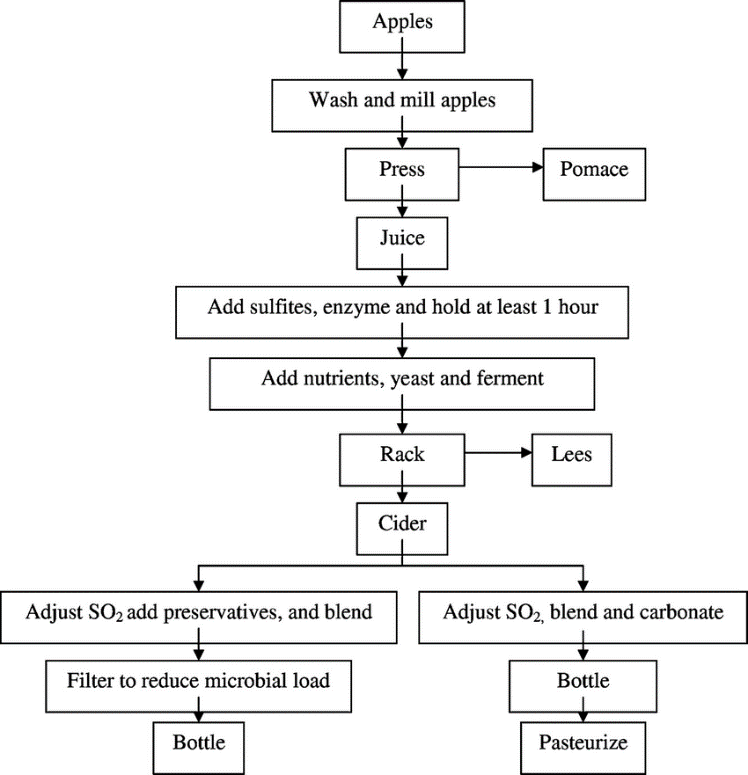

Whether you have recently inherited a few apple trees, or have had a small orchard for some time, one eventually may consider making hard cider. Also, with the gaining popularity of commercial cider, we have seen a resurgence of interest in home production. There are many small local producers of ciders that are bringing the craft back to farmhouse ciders. You too can create your own artisanal cider right at home.

-

You can make hard cider from freshly pressed juice from apples or pears; or purchase fresh apple juice at the market. When searching for juice from the store try to find unfiltered, and preservative-free juice (pasteurized is ok). If you are pressing apples, it is important to use sound, ripe fruit. To obtain the juice the fruit will have to be ground and then pressed.

-

The freezing process will occur after the juice has been pressed from the apples, but before fermentation takes place.

-

The easiest way to make small batches of ice cider is to freeze fresh-pressed cider that condense the natural sugars the cider contains before fermentation. This is equivalent to boiling beer wort to condense the sugars before fermentation. The idea is to get enough sugar to go above the alcohol tolerance of the yeast and still have a pleasant amount of residual sweetness.

-

That is to say that the cider is frozen to concentrate the OG (Original Gravity) above 1.129, and the real residual extract is above .053 of residual sugar. The bottle of Neige started at 1.159, has .060 of residual sugar, and 12% ABV.

-

Freezing the Cider

-

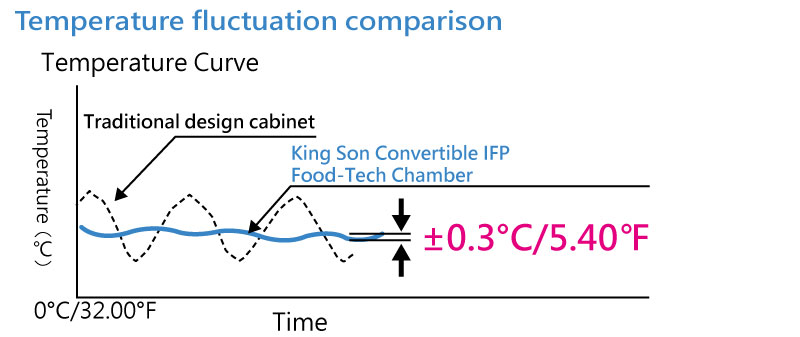

Started with 6 gallons/ 22.71 liters of regular fresh/local cider (pasteurized, but preservative free) and added 1/2 tsp of pectic enzyme to each gallon. After allowing the enzyme to work on clearing the cider for a few hours, and followed by racked the cider into the bottling bucket. Then put it into the chest freezer which had set to 20°F/-6.667°C. It took just 24 hours to freeze the cider into a thick icy slush, which left it there for the next few days, because the freezer temperature fluctuation cycles +/- 3 ℉ degrees (±1.667℃), hoping that would be enough to let the sugary portion of the cider separate from the frozen water.

-

-

-

Extraction

-

Once the cider is frozen solid, you can begin to slowly melt the cider to separate the ice from the extract.

-

Took the bucket out of the freezer and tried to open the spigot, hoping that like a frozen pond the ice was simply a layer on top of the cider. Sadly, a ring of ice had formed around the edge of the bucket rendering the spigot useless. However, under 1/2 inch (1.27cm) of ice the middle column was still liquid so it can pour this portion out through a metal strainer. This yielded about 1.5 gallons/5.678 liters of 1.082 OG (Original Gravity) cider (a 60% increase over the original juice). Not quite as strong or as much as looking for, but a good start.

-

-

Over the next hour the frozen cider slowly melted releasing more concentrated cider before the rest of the water (you can see how clear the ice the top got) that able to pour off another 0.5 gallon/1.892 liters of cider.

-

With only 2 gallons to work that it would be simpler to just ferment it out as is. So after letting the cider warm up to 60°F/15.56°C to give it a shot of oxygen, some yeast nutrient, and the yeast slurry from this year's batch of normal cider (nothing but cider, pectic enzyme, and Wyeast's Cider yeast).

-

(Source:

-

Ice Cider

-

-

Flowchart of typical steps and procedures in modern cider-making

-

Flowchart of typical steps and procedures in modern cider-making. Source: From Valois 2007

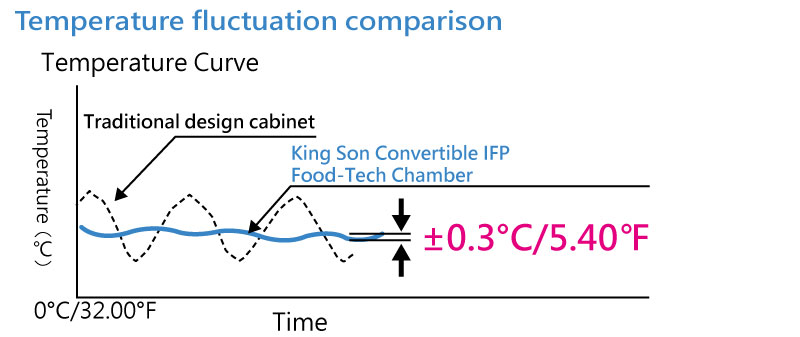

King Son Convertible IFP Superchiller, the superchilling solution to freeze process fresh-pressed cider at -4°C/24.80°F to produce artificial iced wine.

-

King Son Convertible IFP Superchiller is a Convertible Temperature Equipment that operates at a chilled, frozen, or variable temperature condition between approximately (+6°C/42.8°F to -12°C/10.4°F).

-

King Son Convertible IFP Superchiller is a new refrigeration and food preservation solution for the modern AIoT-era. It is incorporated with A7 Intelligent Food-Tech Controller and designed with Constant Temperature and Humidity Multiple Points Monitoring and Servo Control Technology to perform Convertible Temperature Refrigeration System between precision refrigeration and precision freezing for 6 novel next generation refrigeration technologies.

-

King Son Constancy Precision Refrigeration Technology (0°C/32.00°F to 6°C/42.80°F)

-

King Son Constancy IFP Chilling Technology (0°C/32.00°F – above Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Technology (-1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Thawing/Tempering Technology (-2°C/28.40°F to -5°C/23.00°F)

-

King Son Constancy Precision Cryoconcentration Technology (-4℃/24.80℉ to -12°C/10.4°F)

-

King Son Constancy Precision Freezing Technology (-12°C/10.40℉)

-

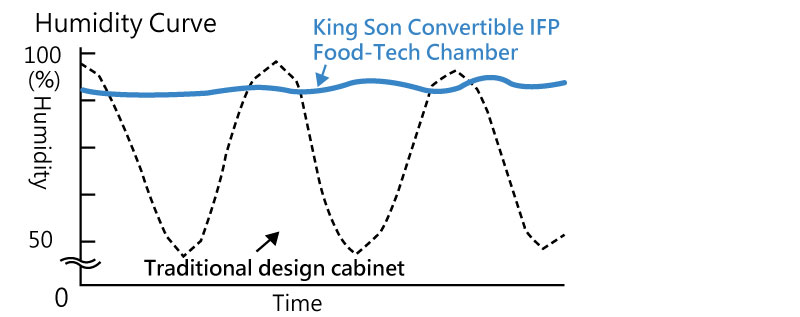

that preserves and processes food in uniform conditions and environments, with temperature fluctuations ±0.3°C/0.54°F and humidity fluctuations ±5%.

-

King Son Convertible IFP Superchiller is an AIoT machine which incorporates King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform for remote distance servicing and collaboration – thus helping build new partnership opportunities through IoT eco-system.