King Son Convertible IFP Superchilling Thawer Overview

King Son Convertible IFP Superchilling Thawer Overview

King Son Convertible IFP Superchilling Thawer is a machinery, plant or laboratory equipment designed for the treatment of materials by a process involving a change of temperature such as cooling and refrigeration for refrigerated food process and beverage preservation.

King Son Convertible IFP Superchilling Thawer is also a machinery for the preparation of meat or poultry, is a food process and preservation equipment.

King Son Convertible IFP Superchilling Thawer is a Convertible Temperature Equipment that operates at a chilled, frozen, or variable temperature condition between approximately (6°C/42.8℉ to -12°C/10.4℉), which can display, processes and preserves merchandise and other perishable materials horizontally, semi-vertically, or vertically; with hinged transparent doors; that also has a user adjustable application temperature set point within the operating range of (6°C/42.8℉ to -12°C/10.4℉); and connected to a self-contained condensing unit.

King Son Convertible IFP Superchilling Thawer is a new refrigeration and food preservation solution for the modern AIoT-era. It is incorporated with A7 Intelligent Food-Tech Controller and designed with Constant Temperature and Humidity Multiple Points Monitoring and Servo Control Technology to perform Convertible Temperature Refrigeration System between precision refrigeration and precision freezing for 5 novel next generation refrigeration technologies.

King Son Convertible IFP Superchilling Thawer is also a machinery for the preparation of meat or poultry, is a food process and preservation equipment.

King Son Convertible IFP Superchilling Thawer is a Convertible Temperature Equipment that operates at a chilled, frozen, or variable temperature condition between approximately (6°C/42.8℉ to -12°C/10.4℉), which can display, processes and preserves merchandise and other perishable materials horizontally, semi-vertically, or vertically; with hinged transparent doors; that also has a user adjustable application temperature set point within the operating range of (6°C/42.8℉ to -12°C/10.4℉); and connected to a self-contained condensing unit.

King Son Convertible IFP Superchilling Thawer is a new refrigeration and food preservation solution for the modern AIoT-era. It is incorporated with A7 Intelligent Food-Tech Controller and designed with Constant Temperature and Humidity Multiple Points Monitoring and Servo Control Technology to perform Convertible Temperature Refrigeration System between precision refrigeration and precision freezing for 5 novel next generation refrigeration technologies.

-

King Son Constancy Precision Refrigeration Technology (0°C/32.00℉ to 6°C/42.80℉)

-

King Son Constancy IFP Chilling Technology (0°C/32.00℉ – above Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Technology (-1°C/30.20℉ to -2°C/28.40℉, just below Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Thawing/Tempering Technology (-2°C/28.40℉ to -5°C/23.00℉)

-

King Son Constancy Precision Freezing Technology (-12°C/10.40℉)

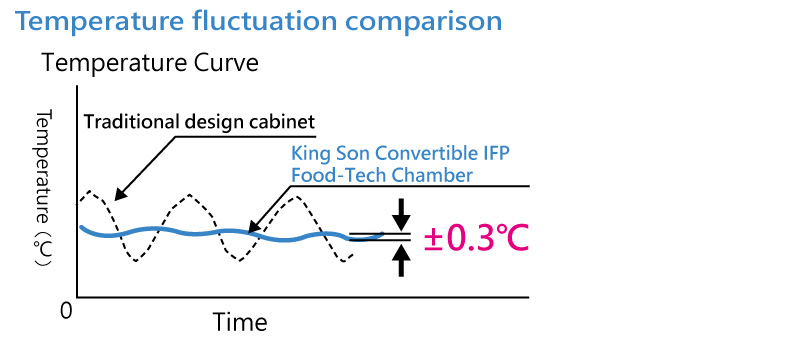

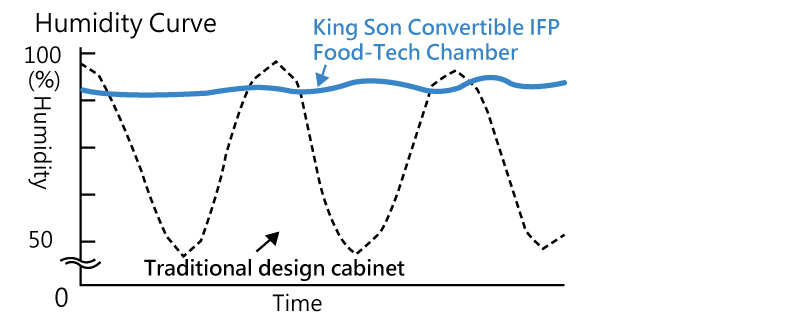

that preserves and processes food in uniform conditions and environments, with temperature fluctuations ±0.3°C/0.54℉ and humidity fluctuations ±5%. King Son Convertible IFP Superchilling Thawer is an AIoT machine which incorporates King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform for remote distance servicing and collaboration – thus helping build new partnership opportunities through IoT eco-system.

King Son Convertible IFP Superchilling Thawer

King Son Convertible IFP Superchilling Thawer

-

King Son Convertible IFP Superchilling Thawer is designed with King Son Constancy IFP Superchilling Technology mainly, specifically designed applied for frozen fish and meat to thaw process and preserve at -1°C/30.20℉ to -2°C/28.40℉, just below Initial Freezing Point of food, with thin freezing in the outer layer of the food that maintains thawed food to extend shelf-life and retains high food quality and also suppress growth of harmful microbes.

-

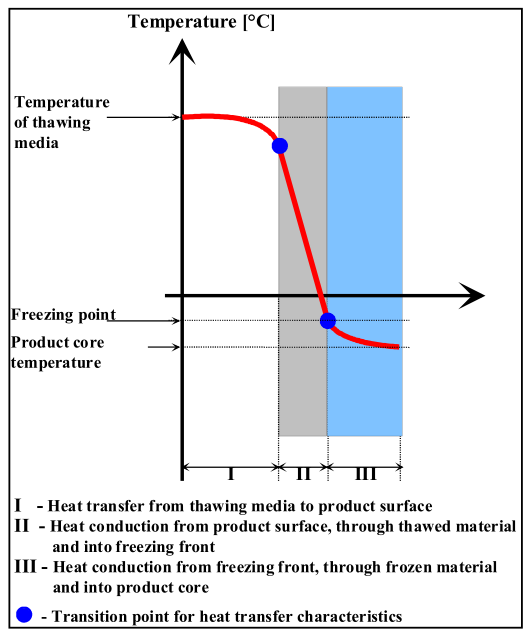

Figure 1. Figure 2.7 Schematic drawing over the three mechanisms of the Convection/conduction thawing principle.

-

(Source: Anders Haugland/INDUSTRIAL THAWING OF FISH - to improve quality, yield and capacity, Chap. 2 Industrial thawing, page 11

-

INDUSTRIAL THAWING OF FISH - to improve quality, yield and capacity

What is thawing?

-

Thawing is the process of changing a product from frozen to unfrozen. It involves transferring heat to a frozen product to melt the ice that was formed within the flesh during the freezing process. The point at which ice crystals are converted back to water occurs completely when the temperature throughout the seafood reaches -1°C/30.20℉. The time required to melt all the ice in the frozen seafood is the thawing time.

Temperature changes during thawing

-

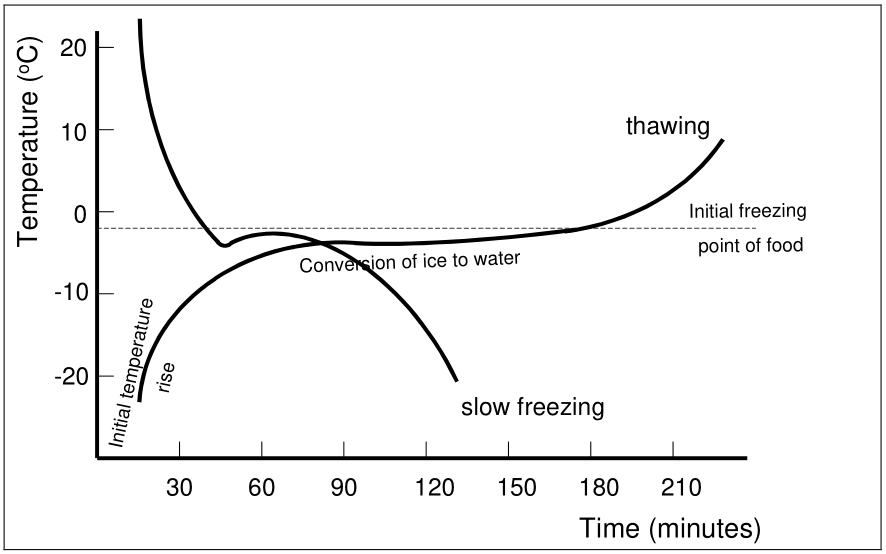

Figure 1 shows the typical temperature changes that occur in foods during freezing and thawing.

-

Figure 1 - Temperature changes during thawing

-

(Source:

-

Seafood thawing, February 2008, Research & Development Department, SR598, page 3, ISBN - 0 903941 99 6

-

The initial rapid temperature rise during thawing is due to the presence of a layer of ice around the food material which forms a protective glaze. This ice glaze layer has a higher thermal conductivity than water and thaws quickly during the early stages.

-

As the surface ice (glaze) melts, the thawing rate slows down and there follows a long period when the temperature of the food is close to that of melting ice. At this time, the energy to overcome the latent heat (i.e. to change the solid ice to liquid water) needs to be overcome. It is also the period where any cellular damage caused by, for example, poor handling before freezing, excessively slow freezing or poor temperature controls, result in the release of cell constituents to form ‘drip losses’.

-

Commercially, foods can be thawed to just below the freezing point to retain a firm texture for subsequent processing. This process is known as tempering.

-

(Source:

-

Seafood thawing, February 2008, Research & Development Department, SR598, page 3, ISBN - 0 903941 99 6

-

What is Initial Freezing Point (IFP)?

-

The Initial Freezing Point (IFP) is the temperature in at any fixed pressure at which the liquid and solid phases of a substance of specified composition is in equilibrium. The freezing point of water is 0°C/32.00℉.

Some facts about fish thawing

-

Thawed fish spoil as rapidly as wet fish, and must be kept chilled until required; the thawed fish can be iced, or the fish can sometimes be removed from the thawer just before thawing is completed, so that the fish has its own small reserve of cold.

-

Fish will normally lose some weight on thawing; this drip loss may amount to up to 5% for properly frozen and cold stored white fish, though it can be considerably more if insufficient attention is paid to thawing procedure. Very little, if any, of this loss is directly attributable to the thawing process itself; some is accounted for by changes in the nature of the flesh during cold storage, some is due to the melting of any glaze that has been coated onto the fish. Fish that have been frozen before the onset of rigor may complete the rigor process after thawing if the changes have not already taken place gradually during cold storage; this effect is usually more obvious with fillets than whole fish, the fillets contracting noticeably in length. It may be necessary to thaw pre-rigor fillets slowly in order to avoid distortion or shrinkage.

-

-

(Source:

-

FAO CORPORATE DOCUMENT REPOSITORY, produced by: Torry Research Station, Title: Thawing frozen fish

-

INDUSTRIAL SUPERCHILLING THAWING OF FISH - to improve quality, yield and capacity

-

2.7 Regulations

-

The Norwegian quality regulation for fish and fish products did until 10th of June 1998 demand that the thawing should be finalized as soon as the coldest part of the product reached -1°C/30.20℉, and there should be no delay in the further processing. Each shift should process the fish thawed within the same shift, and thawed fish should if necessary be iced in order to give the product a temperature of 0°C/32.00℉.

-

(Source:

-

Anders Haugland/ INDUSTRIAL THAWING OF FISH - to improve quality, yield and capacity, Chap. 2 Industrial thawing, page 27

-

King Son Constancy IFP Superchilling Technology

-

It is designed by King Son Constant Temperature and humidity multiple points monitoring and servo control technology to produce, achieve and perform superchilling conditions that meets the requirements for superchilling thawing process and preservation.

-

0.01°C/0.018℉ controlled resolution in constant temperature above Initial Freezing Point, with controlled temperature fluctuation ±0.3°C/0.54℉

-

0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, with controlled humidity fluctuation ±5% RH.

-

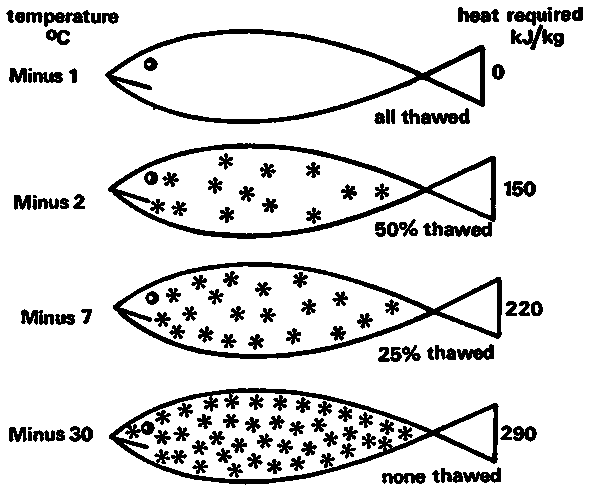

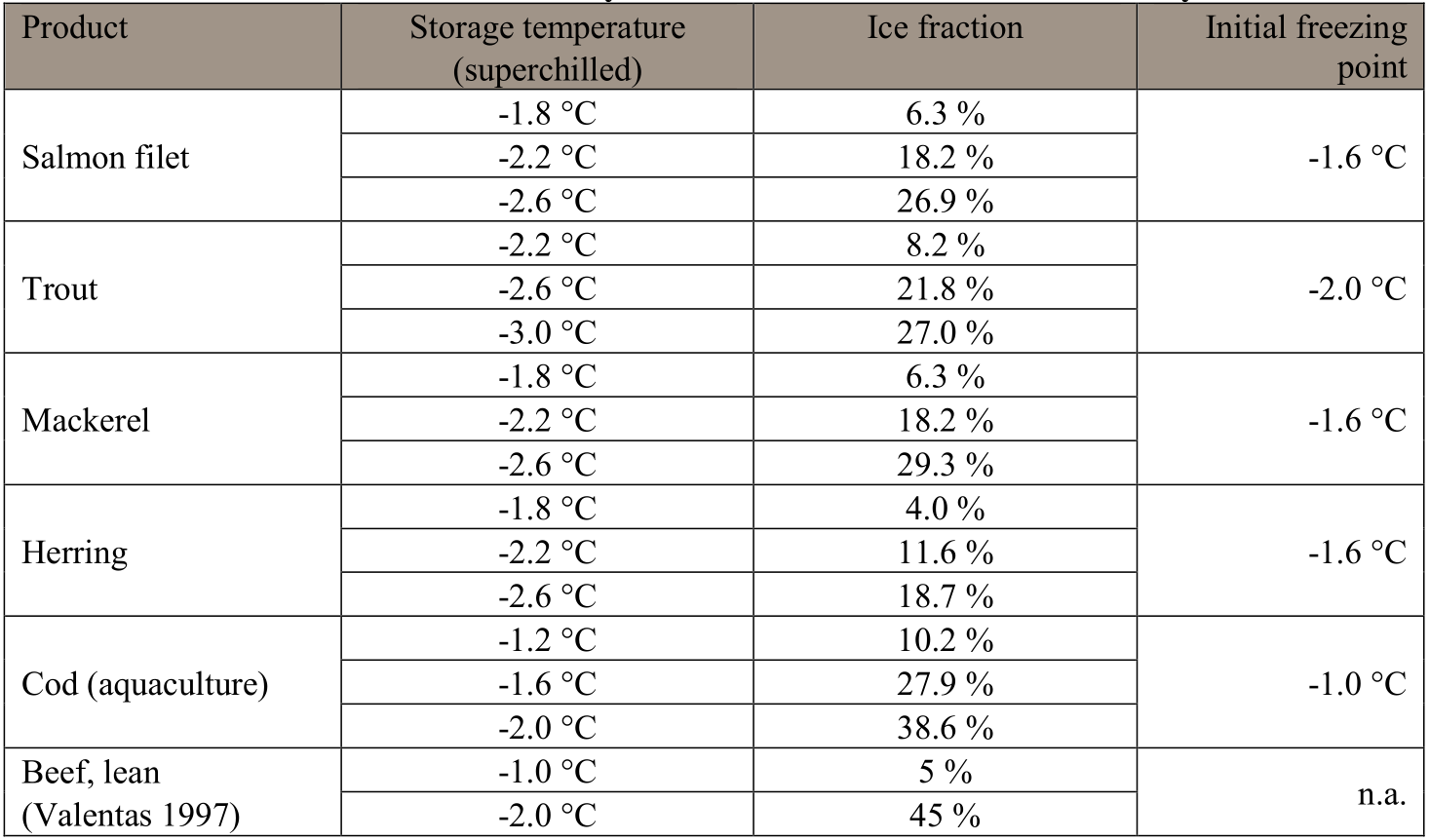

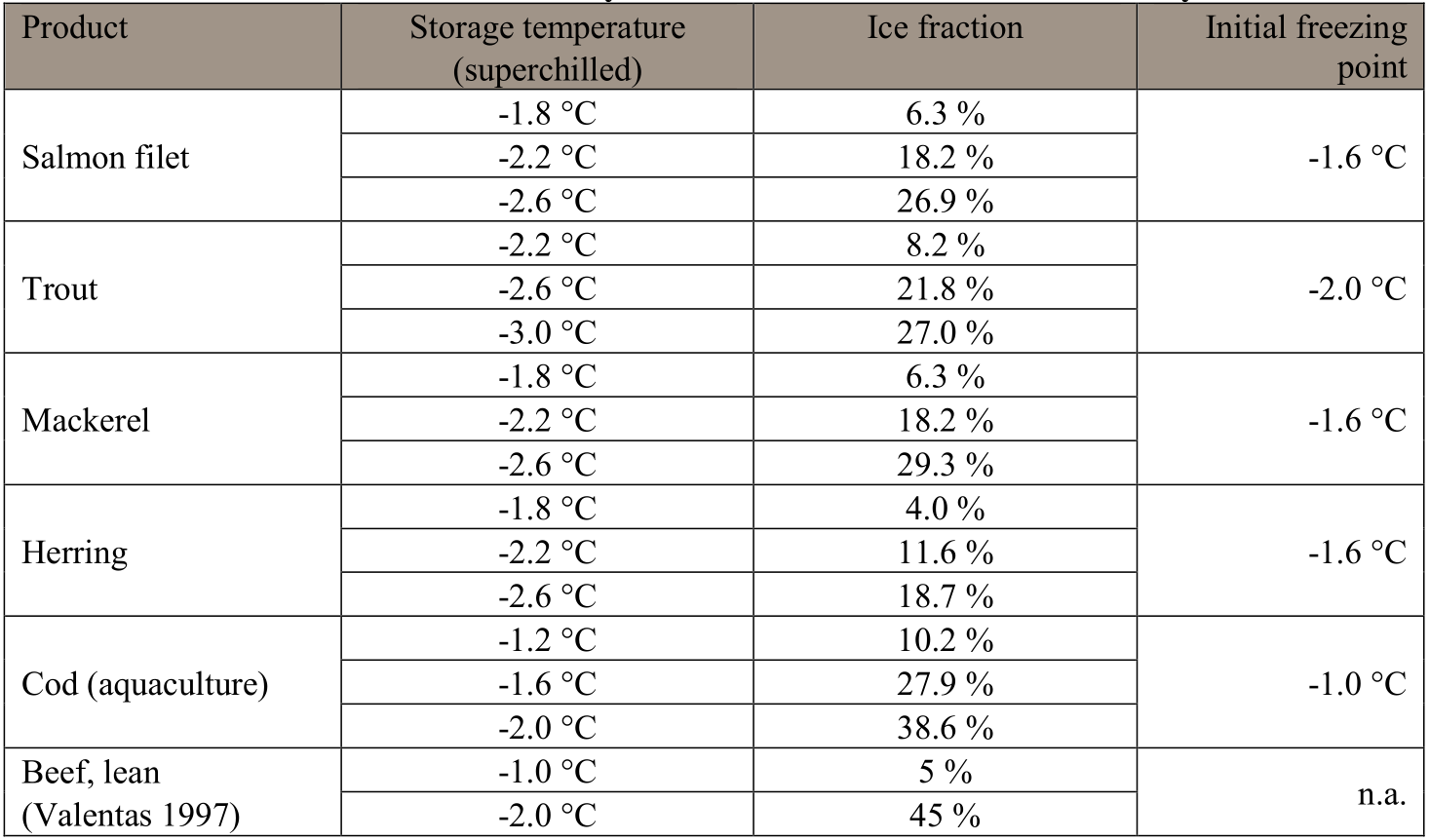

To avoid low quality influences in the superchilled thawing food, recommended the degree of superchilling (ice fraction) is between 5% and 30% inside the products and that ice fraction larger than 30% inside the product will result in low quality of the food. Therefore, optimal 20 % ice fraction has been recommended.

-

-

Table 1. Relation between storage temperature and ice fraction for some selected products. Product variations make it necessary to evaluate the ice fraction individually.

-

Michael Bantle et al./ SINTEF Energy Research/ Superchilling of organic food, Part 1: Concept, State-of-the-Art and Potential for small scale implementation, page 15

-

(Source:

What is superchilling?

-

The term ‘superchilling’, is also called partial freezing, light freezing, and deep chilling, which describe a food process and preservation method, where crust freezing, with thin freezing in the outer layer of the food, about 10% to 30% of food's water content is frozen, without complete freezing. During superchilling, the temperature of food is lowered to between -1°C/30.20℉ and -2°C/28.40℉, below the initial freezing point of food. After initial surface freezing, the ice distribution equilibrates and food obtains a uniform temperature at which it is maintained during preservation.

Why needs superchilling?

-

Fresh foods demand novel refrigeration methods to preserve food products at controlled low temperature through complete cold chain from production, transportation and storage. Storage temperature is important in all stages of the products shelf life, and storage by producer, the retailer and the consumer. The market opinion survey results are fresh foods are better than frozen foods. Therefore, the demand for keeping the food fresh is increasing, and the requirement for keeping the right temperatures are essential. It is therefore important to develop and promote what and how the superchilled thawed products with a low content of ice do have the same quality characteristics like fresh products.

-

Superchilling thawing have great potential to enable safe, high quality and long term storage of foods without the consumer perceived detrimental effects of freezing. Energy and environmental benefits are envisaged due to reduced heat loads and higher storage temperatures (when compared to frozen food).

Superchilling is potential and substantial alternative for freezing

The main efforts now are how to use the experimental research knowledge of superchilling thawing to produce industrial economic scale in the food industry.

In the fast-moving food industry of today, keeping up with the competition is of vital importance. Customers demand better and “newer” products almost every other day, and they also expect affordable prices and high availability. Being able to meet these demands means inventing new food products and using the best technology for processing them and keeping them nutrition, tasty and healthy. With decades of product liability testing instrument experiences and as a Food-Tech equipment manufacturer, King Son is able to provide a wide variety of high-quality, state-of-the-art King Son Convertible IFP Food-Tech Chamber for food industry.

King Son Convertible IFP Superchilling Thawer commercializes superchilling thawing process and preservation for food industry in economic scale value

The main efforts now are how to use the experimental research knowledge of superchilling thawing to produce industrial economic scale in the food industry.

In the fast-moving food industry of today, keeping up with the competition is of vital importance. Customers demand better and “newer” products almost every other day, and they also expect affordable prices and high availability. Being able to meet these demands means inventing new food products and using the best technology for processing them and keeping them nutrition, tasty and healthy. With decades of product liability testing instrument experiences and as a Food-Tech equipment manufacturer, King Son is able to provide a wide variety of high-quality, state-of-the-art King Son Convertible IFP Food-Tech Chamber for food industry.

King Son Convertible IFP Superchilling Thawer commercializes superchilling thawing process and preservation for food industry in economic scale value

-

King Son Convertible IFP Superchilling Thawer is a novel generation Food-Tech equipment after traditional refrigerator and freezer, which is designed with King Son Constancy IFP Superchilling Technology to thaw process and preserve thawed food in the temperature of -1°C/30.20℉ to -2°C/28.40℉, just below Initial Freezing Point (IFP) of food, with thin freezing in the outer layer of the food that maintains thawed food to extend shelf-life and retains high food quality and also suppress growth of harmful microbes, in which the controlled constant temperature and humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5 %.

-

After initial surface superchilling, the ice distribution equilibrates and food obtains a uniform temperature at which it is maintained during preservation.

-

King Son Constancy IFP Superchilling Technology is designed by King Son Constant Temperature and humidity multiple points monitoring and servo control technology to produce, achieve and perform superchilling conditions, that meets the requirements for superchilling thawing process and preservation.

-

0.01°C/0.018℉ controlled resolution in constant temperature above Initial Freezing Point, with controlled temperature fluctuation ±0.3°C/0.54℉

-

0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, with controlled humidity fluctuation ±5% RH.

-

-

King Son Convertible IFP Superchilling Thawer commercializes the economic value of superchilling thawing at -1°C/30.20℉ to -2°C/28.40℉, just below Initial Freezing Point (IFP), for food thawing process and preservation in food industry.

-

Superchilling Thawing Commercial Benefits

-

Reduced drip loss

-

Retained product quality

-

Reasonable defrosting time to meet thawed quality

-

High degree of homogeneity

-

Better hygiene

-

-

The initial freezing points of most foods are between -0.5°C/31.10℉ and -2.8°C/26.96℉

-

King Son Convertible IFP Superchilling Thawer application

-

Fresh hold, freshness contained

-

Preservation

-

Thawing

-

Tempering:

-

Commercially, foods can be thawed to just below the freezing point to retain a firm texture for subsequent processing. This process is known as tempering.

-

Tempering is the process of taking a product to a temperature where a substantial amount of the water in the product is in the form of ice but not all the water has turned to ice. This temperature must be below the freezing point and is usually between -5°C/23.00℉ to -2.8°C/26.96℉. At this state the product is rigid, but not hard and thus easier to cut. The product can either be cooled to this state from a temperature above the freezing point or warmed from a frozen temperature. Unless tempering is controlled well, product variability is liable to be high. Quite small differences in temperature during processing operations such as pre-breaking or cutting can have quite large effects on product quality. The consequences of processing below the zone of optimum temper (under-tempering) may be blade breakage and yield loss from shattered product, excessive fines, and slices of non-uniform thickness. The consequences of over-tempering may also be in the form of yield loss from ragged edges and incomplete shearing of tissue resulting in pearling.

-

-

- (Source:

- Thawing and tempering - FRPERC.com

- http://www.frperc.com/FRPERC.com/Thawing_and_tempering.html

-

CHAPTER 8 Fahrenheit THERMAL PROPERTIES OF FOODS, Table 3 Unfrozen Composition Data, Initial Freezing Point, and Specific Heats of Foods.

-

CHAPTER 9 Celsius THERMAL PROPERTIES OF FOODS,Table 3 Unfrozen Composition Data, Initial Freezing Point, and Specific Heats of Foods.

By what and How King Son Convertible IFP Superchilling Thawer does superchilling thawing process and preservation?

-

Ice-forming and re-crystallization can cause microstructural changes to food tissue during freezing, resulting in cell dehydration, drip loss and tissue shrinkage during thawing.

-

Frozen foods must be thawed well before they were processed. It would lead to microbial growth and spoilage owing to enzymes and oxidation reaction when thawing is not properly. The juice inside of the thawed food must sufficiently flowed into the cell to prevents the loss of nutritional components. Choosing the right thawing method is essential for the subsequent processing of frozen foods.

-

A rule of thumb when freezing and thawing meat is to “freeze it fast and thaw it slowly”. This minimizes the formation of larger ice crystals which can break cell membranes, causing moisture loss during thawing and cooking.

-

Rapid thawing is NOT recommended. It has the potential to do as much damage to frozen beef as slow freezing. Rapid thawing provides a greater opportunity for the formation of new, larger ice crystals and increased microbial growth, especially when frozen beef is thawed at a high temperature. The more desirable smaller ice crystals formed during rapid freezing may thaw too quickly and then refreeze into less desirable larger crystals, which can rupture muscle cells. This can result in increased purge loss during thawing, as well as greater drip loss during cooking. Slow thawing reduces the opportunity for smaller ice crystals to thaw and refreeze into larger crystals.

-

Unless beef products are being cooked directly from the frozen state, they should be thawed slowly with the packaging material left intact in order to minimize drip loss. Thawing methods tend to affect the amount of drip losses in direct proportion to the rate of thawing. Factors to consider when thawing frozen beef products include meat product size and the temperature used for the thawing process.

-

The recommended procedure is to thaw frozen beef products at refrigerated temperatures, between 0°C/32°F and 1.67°C /35°F. This is a slow process, so one must plan ahead. The thawing process is frequently abused, however, by thawing frozen beef products at room temperature or in warm water. These procedures can speed up the thawing process, but they also greatly increase the rate of microbial growth and can cause excessive drip losses. In fact, thawing frozen beef too rapidly at higher temperatures can actually undo the benefits of quick freezing.

-

Thawed meat products should be used promptly. In fact, cooking from the frozen or partially thawed state largely eliminates the opportunity for any appreciable microbial growth to take place.

-

At temperatures around the initial freezing point, the texture is very much depending on product temperature. For some products like fat mackerel industrial experience shows that it is almost impossible to cut a first class fillet when the product is completely thawed (contains no ice). This means that temperature control is imperative for these kind of products, and that this fact has to be taken seriously in the process and equipment design.

-

Controlled superchilling thawing applied in clip fish and fillet production offer benefits in terms of higher yield and better quality. The product temperature should be just below the initial freezing point of the product. Normally this means that the product temperature should be approximately -1°C/30.20℉. Products containing a small amount of internal ice after thawing will give higher yields and experience lower temperatures during filleting, trimming and grading. The required energy for refreezing will therefore be reduced, thus increasing the capacity on the freezers. The reduced product temperature during processing will also reduce the risk for microbial contamination.

-

King Son Convertible IFP Superchilling Thawer is designed with King Son Constancy IFP Superchilling Technology in temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% that precisely to perform frozen food thawed in superchilling uniformity conditions and environments (-1°C/30.20℉ to -2°C/28.40℉, 85% - 95% high humidity), where thawed food is in light freezing preserved its best texture characteristics available for process, with lower weight/drip loss, higher yield, moisture content and lower bacterial count that ensures thawed foods in best product value.

-

King Son Constancy IFP Superchilling Technology is designed by King Son Constant Temperature and humidity multiple points monitoring and servo control technology to produce, achieve and perform superchilling conditions, that meets the requirements for superchilling thawing process and preservation.

-

0.01°C/0.018℉ controlled resolution in constant temperature above Initial Freezing Point, with controlled temperature fluctuation ±0.3°C/0.54℉.

-

0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, with controlled humidity fluctuation ±5% RH.

-

-

Retained thawing food quality and high degree of homogeneity in King Son Convertible IFP Superchilling Thawer

-

The best way to minimize the drip loss is to thaw the fish up to initial freezing point and then apply tempering to even out the temperature of the batch food.

-

-

Why choose King Son for the best superchilling thawing process, storage and preservation solutions?

-

King Son Convertible IFP Superchilling Thawer provides frozen food ideal IFP Superchilling thawing process condition and preservation environment.

-

Superchilling thawing process and preserve food naturally and safely in King Son Convertible IFP Superchilling Thawer.

-

King Son Convertible IFP Superchilling Thawer monitors and controls superchilling thawing factors.

-

King Son Convertible IFP Superchilling Thawer provides UVC Air Ventilation Bacteriostatic System for antibacterial and microbiological control.

-

King Son Convertible IFP Superchilling Thawer is available to preserves food in Superchilling.

-

Superchilling Thawing-Tempering-Superchilling preservation Multiple functions

-

King Son Convertible IFP Superchilling Thawer provides food with an ideal uniformity conditions and environment, where thawing processes and preserves food in controlled constant temperature at -1°C/30.20℉ to -2°C/28.40℉, just below Initial Freezing Point (IFP) of food and 95% high humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% and that embraced in UVC air ventilation bacteriostatic environment which ensures food storage and preservation safety.

-

King Son Convertible IFP Superchilling Thawer thaws fish up to the initial freezing point and then allowing it to temper is then advised to keep the material quality as high as possible after thawing. The maximum product temperature should never go over 3°C/37.40℉ during the thawing process to minimize bacterial growth and drying.

-

After thawing the fish must be given a chance to temper and reach even temperatures throughout the whole volume.

-

Once finished thawing process, thawing food can be preserved in Superchilling conditions (-1.5°C/29.30°F to -2°C/28.40°F, 85% - 95% high humidity) for 2-3 weeks.

-

King Son Convertible IFP Superchilling Thawer provides food constant superchilling thawing process and preservation conditions and environments

-

King Son Convertible IFP Superchilling Thawer provides food with an ideal uniformity conditions and environment, where thawing processes and preserves food in controlled constant temperature at -1°C/30.20℉ to -2°C/28.40℉, just below Initial Freezing Point (IFP) of food and 95% high humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% and that embraced in UVC air ventilation bacteriostatic environment which ensures food storage and preservation safety.

-

Results obtained from shrimp thawing study suggests

-

Shrimp thawed using the thawing chamber did not exceed -1°C/30.20℉ throughout the thawing experiment, in which microbial growth during thawing was also avoided that indicated that the thawing chamber has potential for the food service industry to produce uniformly thawed products under sanitary conditions.

-

Quality and safety of shrimp thawed using a constant temperature thawing chamber were better maintained than room temperature and running water thawing processes."

-

Superchilling thawing process and preserve food naturally and safely in King Son Convertible IFP Superchiller

-

Superchilling thawing process is a new method preserved thawed food for a whole month, without the use of chemical additives, examples include salt in water, alcohol in water, or the mixing of two solids such as impurities in a finely powdered drug.

-

Thawing food in King Son Convertible IFP Superchilling Thawer naturally, without adding salt to lower freezing point for better health food, without waste water by using immersion thawing and that safely embraced in UVC air ventilation bacteriostatic environment which ensures thawing food safety.

-

Additional food can be placed in King Son Convertible IFP Superchilling Thawer at any point during the thawing process with no adverse effects, enabling a continual supply of thawed food.

-

Built with King Son renowned product quality and reliability, King Son Convertible IFP Superchilling Thawer has an impressive 84 kg and 168 kg capacity for 2 doors and 4 doors thawer.

King Son Convertible IFP Superchilling Thawer monitors and controls superchilling thawing process and preservation factors

-

Temperature, with fluctuation ±0.3°C/0.54℉

-

Temperature fluctuation affects food quality and safety.

-

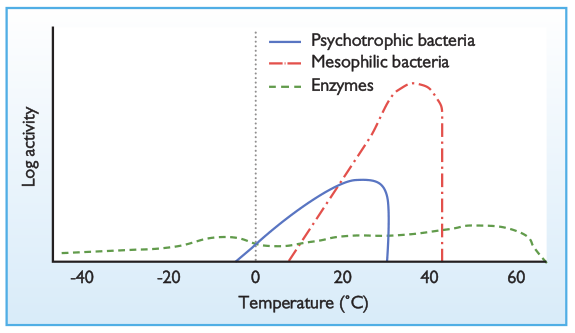

It is well known that both enzymatic and microbiological activity are greatly influenced by temperature that temperature changes have greater impact on microbiological growth than on enzymatic activity for food safety.

-

-

Figure 2. Relative enzyme activity and microbial growth rate in relation to temperature (Andersen et al., 1965)

-

(Source:

-

The evolving story of fish shelf-life management, International Meat Topics — Volume 1 Number 1, Page 1,

-

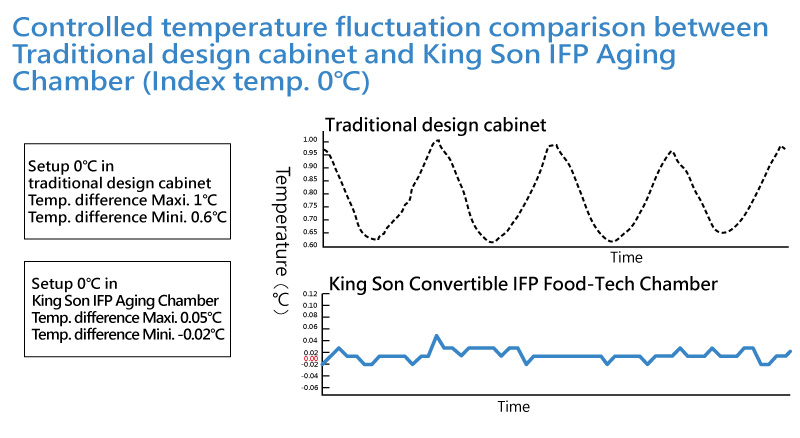

To eliminate temperature fluctuation impacts on food quality and safety, King Son researched, developed and launched King Son Constancy IFP Superchilling Technology in 2015 that provides a unique constant temperature stability ±0.3°C/0.54℉, which reduces the traditional temperature fluctuation from ±5°C/9℉ down to ±0.3°C/0.54℉.

-

In addition, it should also be noted that reducing temperature variations to a minimum extent during superchilling storage is of great importance. Minor temperature changes may lead to ice melting and recrystallization, thus changing the size and distribution of ice crystals inside food, and increasing the amount of myofiber detachment or breakage during storage, eventually resulting in drip loss after thawing. Therefore, keeping a stable temperature is critical for reducing drip loss during superchilling storage and preservation.

-

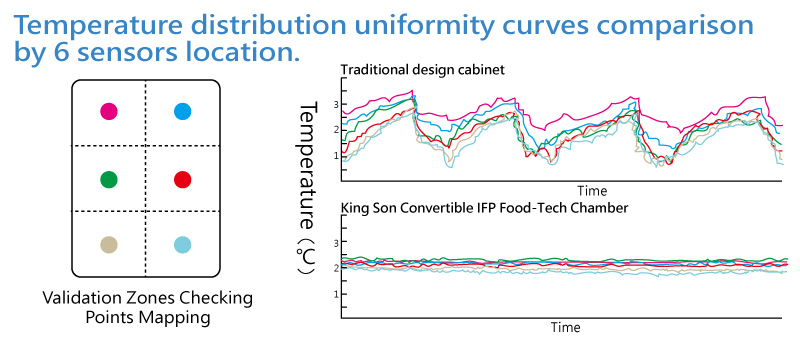

Most current designs in traditional refrigerator and freezer also rely on vapor-compression systems that are turned on or off at high and low set points, resulting in temperature fluctuations that exceed the recommended variation of ±5°C/9℉.

-

Non uniformity temperature distribution in the traditional cabinet is the main reason produced food waste.

-

King Son Convertible IFP Superchilling Thaweris a flexible and effective Superchilling storage and preservation equipment that can meet the demands and fulfill the requests of more research on how to control and keep the required superchilling storage temperature after initial surface freezing of food. The Superchilling preservation temperature should be stable enough to avoid significant levels of ice crystal growth that can cause structural damage during the storage of the superchilled product as well as to keep the degree of superchilling within a narrow margin.

-

Related Humidity, with fluctuation ±5% reduced weight, drip and (water soluble) proteins loss

-

The amount of humidity should be monitored closely, because too much will allow disproportionate microbial growth, whereas too little will cause excessive shrinkage.

-

The humidity of the preservation conditions should be over 90 percent and the air velocity should be low to minimize food dehydration.

-

King Son Convertible IFP Superchilling Thawer is designed to produce 0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, and controlled humidity fluctuation ±5% RH.

-

-

Significant factors affecting the properties of thawed seafood include:

-

Moisture migration, weight loss

-

This is the principal physical change that occurs in frozen foods and has major effects on the physical, chemical and biochemical properties of the final product. It is manifested in several ways; moisture loss by surface evaporation, moisture absorption and redistribution in foods, recrystallization of ice and drip loss during thawing. Having taken great care to freeze foods rapidly and store the frozen products under cold and well-controlled frozen storage conditions, the process of thawing takes precedent in dictating the likely final quality of frozen seafood. The role of water (frozen or unfrozen) in foods is an important consideration. Moisture loss from frozen seafood has important economic consequences and is a major factor in determining the shelf life. Moisture loss during frozen storage can lead to freezer burn and desiccation of the surface layers, making the product unappealing to the manufacturer or consumer. Moisture migration has a significant effect in the form of weight loss; the water that is lost has the same economic value as the product.

-

-

Drip loss

-

This is a form of moisture migration. It is known that fish usually lose weight on thawing. This drip loss may be up to 5% of the original product weight for properly frozen and cold stored whitefish, though it can be more if the thawing process is uncontrolled.

-

The factors that influence thawing drip loss are many and complex. It is determined by a number of factors intrinsic to the food product, the conditions of freezing and the thawing process and conditions. Thawing drip loss is visually unattractive, soluble nutrients are lost from the food and it represents a significant economic loss to the processor.

-

-

By keeping thawing food in the air of sufficiently high humidity, drip loss can be minimized.

-

Fish muscle has been shown to have a tendency to reabsorb some of the water that has been lost from the muscle during freezing. However, this reabsorption is dependent upon the thawing rate and since forced air thawing induces higher rates than still air thawing, the danger is that more drip loss is experienced during this process. However, by keeping the humidity of the air sufficiently high, drip loss can be minimized.

-

Another way to minimize the drip is to thaw the fish up to initial freezing point and then apply tempering to even out the temperature of the batch.

-

-

Air velocity

-

It is equally critical since it acts as a medium for moisture removal from the superchilling thawing process area. Inadequate air velocity will permit undue moisture to condense on the product, and as a result, off-flavors and aromas, as well as spoilage, will occur. On the other hand, if the air velocity is too high, this will result in excessive surface drying, with resulting weight and trim losses.

-

King Son Convertible IFP Superchilling Thawer is incorporated with 360° Air Cooling System, it is a unique design of the wind field, thru that cooling air inputs into to the chamber that produces uniform temperature distribution, so that cooling is more stable, efficient and allows for accurate temperature distribution uniformity inside the chamber.

-

Temperature distribution uniformity curves comparison by 6 sensors location

-

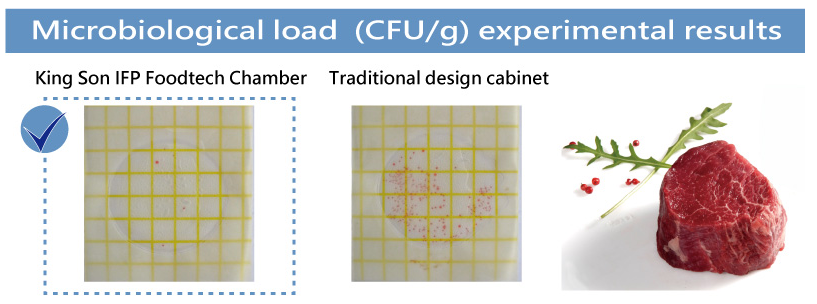

King Son Convertible IFP Superchilling Thawer provides UVC Air Ventilation Bacteriostatic System for antibacterial and microbiological control

-

The use of ultraviolet (UV) light to eliminate bacterial cells is well known for fresh meat. A more sophisticated approach to manage the superchilling process and preservation is to install UV. Air is through the sealed UV channel to circulate in the superchilling thawing process zone of the chamber.

-

King Son UVC Air Ventilation Bacteriostatic System remove the micro-organisms in the chamber enables a safe superchilling thawing food process and preservation environment.

King Son Convertible IFP Superchilling Thawer preserves food in Superchilling temperature

-

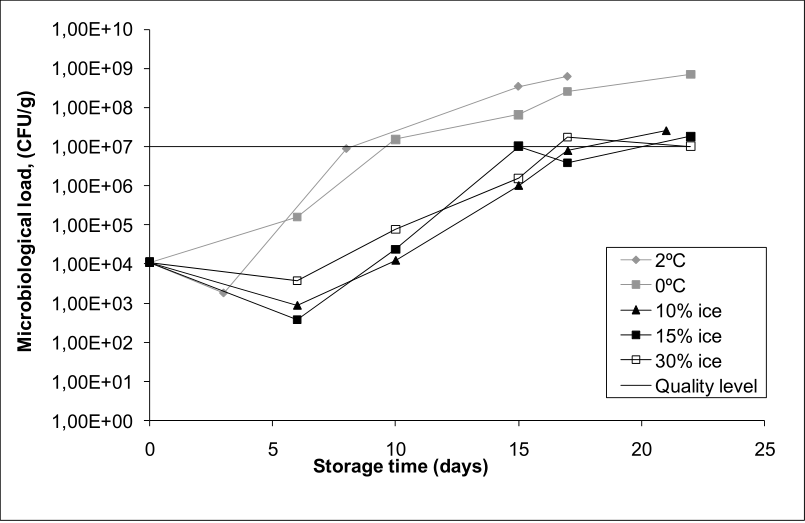

Once finished superchilling thawing process, King Son Convertible IFP Superchilling thawer can switch the thawing process mode to superchilling preservation mode that preserves food in superchilling (-1.5°C/29.30°F to -2°C/28.40°F), with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% which extends the shelf life of the meat for 3 – 4 weeks.

-

The aim of superchilling storage and preservation is to preserve food products at temperatures just below their initial freezing point; low enough to substantially reduce bacterial activity but high enough to avoid significant levels of bigger size ice crystal growth as refreezing does that can cause food structural damage.

-

The quality limit of 107 CFU/g represents a usual microbiological quality measure, above which food is regarded as unfit for human consumption.

-

Figure 3. Microbiological load (total count) for unpacked chilled and superchilled salmon fillets

-

(Source:

-

Stevik, A.M. 2007. Microbiological level of unpacked, chilled and superchilled salmon fillets. In SINTEF Energy Research, Trondheim

Controlled thawing applied in clip fish and fillet production offer benefits in terms of higher yield, and better quality. The product temperature should be just below the initial freezing point of the product. Normally this means that the product temperature should be approximately -1°C/30.20℉. It is however clear that the margins are narrow in this temperature region and that too low temperatures will reduce the yield. Products containing a small amount of internal ice after thawing will give higher yields and experience lower temperatures during filleting, trimming and grading. The required energy for refreezing will therefore be reduced, thus increasing the capacity on the freezers. The reduced product temperature during processing will also reduce the risk for microbial contamination. It seems possible to reduce the overall process time for thawing without compromising the yield or quality.

King Son Superchilling Thawing experimental test results:

-

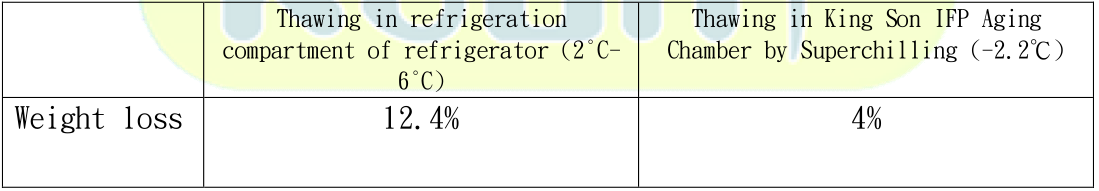

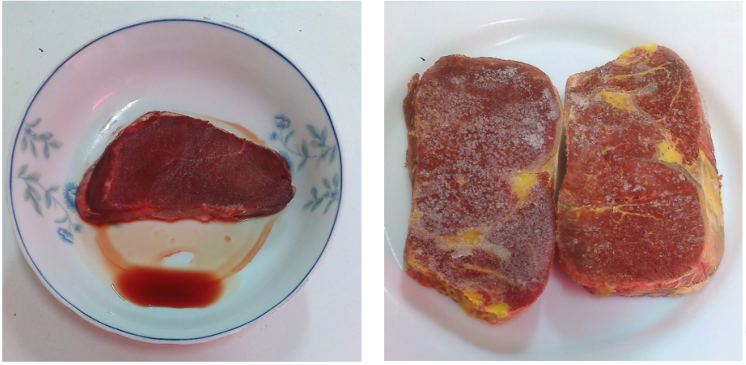

Thaws frozen beef in King Son Convertible IFP Superchilling Thawer (-2.2°C/28.04℉) and refrigeration compartment (2°C/35.60℉-6°C/42.80°F) of refrigerator for 24 hours, the weight loss as below:

-

Learned from above experiment results that Thaws frozen beef by Superchilling (-2.2°C/28.04℉) in King Son Convertible IFP Superchilling Thawer can minimize the weight loss of thawing. The pictures as below shown the actual thawing status of frozen beef.

-

The picture in upper left is the frozen beef thawed 24 hours in refrigeration compartment (2°C/35.60℉-6°C/42.80°F) that shows a lot of drip loss, this result evidences that frozen beef thawed in the refrigeration compartment of refrigerator can cause irreversible damage to the food tissues, resulting in a significant drip loss and mouthfeel deterioration, which in turn causes food nutritional value down and high weight loss.

-

The picture in upper right is the frozen beef thawed 24 hours in King Son Convertible IFP Superchilling Thawer that shows no drip loss by Superchilling (-2.2°C/28.04℉), there is only a very thin ice on the surface of beef which is still pliable and yields to the thumb when pressed, evidences that the beef is ready to process after finished thawing. Most consumers consider a product to be fresh, as opposed to frozen, when it is pliable or when it is not hard to the touch.”

-

In order to further observe whether the thawing in Superchilling performed by King Son Convertible IFP Superchilling Thawer that cause damages to food tissue or not, the Superchilling thawing beef (shown in upper right picture) is placed at room temperature for 30 minutes and the results are shown below:

-

Above actual photo shows that there is no drip loss happened after the Superchilling thawing beef acclimated to room temperature, this results evidences that the Superchilling Thawing process in King Son Convertible IFP Superchilling Thawer is hardly to produce impacts on food tissue that preserves food’s original nutrients and keep the taste same.

-

Conclusion

-

Thaws frozen food by Superchilling temperature (-2.2°C/28.04℉) in King Son Convertible IFP Superchilling Thawer can minimize the weight loss of thawing. The traditional thawing method, due to the temperature difference is too large and the temperature fluctuation too much, easily lead to the food tissue damages in the thawing process and make food taste worse, and cause a lot of drip loss and nutrient disappeared.

-

King Son Convertible IFP Superchilling Thawer can provide frozen food thawing in Superchilling, at above 85% constant high humidity environment that minimizes the weight loss in thawing process, it is hardly to produce impacts on food tissue and preserves food’s original nutrients and keep the taste well after finished thawing.

-

King Son Convertible IFP Superchilling Thawer is a designated ‘plug-and-play’ production unit for small-sized food processors who need a cost-effective method to superchilling thawing their frozen food before next process operations.

King Son Convertible IFP Superchiller is designed for mechanical freezing process to superchilling thawing frozen food at standard speeds.

King Son Convertible IFP Superchiller is designed for mechanical freezing process to superchilling thawing frozen food at standard speeds.

-

Small batch superchilling thawing by mechanical freezing method to thaw frozen food and preserve thawed food, such as meat/fish fillets, thin or flat products, including high-value individually quick-frozen (IQF) products. IQF product, e.g.: Fish fillets, Meat in pieces.

-

Small Batch superchilling thawing frozen food to stabilized soft food, fish and meat by mechanical freezing method before further processing.

-

Improve throughput, yield and hygiene for delicious product in slicing process operation.

-

Small batch superchilling thawing frozen raw meats by mechanical freezing method for safer chilled storage, preservation and distribution.

-

Food types available application

-

Meat

-

Poultry

-

Sea food fillets

-

-

King Son Convertible IFP Superchilling Thawer plays a key role in the final stage(s) of the superchilling thawing value chain including:

-

Benefiting high-volume thawing machine producers requiring rapid superchilling thawing processes in food processing factory. King Son Convertible IFP Superchilling Thawer serves as a superchilling storage and preservation solution for superchilled thawed foods in retailers operating in the final stages of superchilling value chain.

-

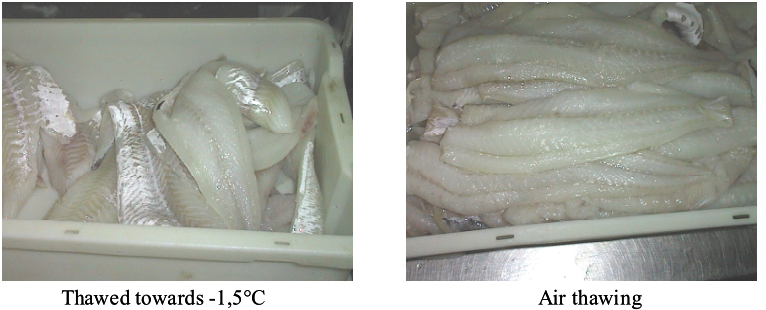

Figure 5.22 The trimmed fillets after thawing. RSW thawed towards -1.5°C/29.30℉ vs. Air blast thawed product.

-

(Source: Anders Haugland/ INDUSTRIAL THAWING OF FISH - to improve quality, yield and capacity, Chap. 5 Thawing of lean fish – Cod, page 135

-

King Son Convertible IFP Superchilling Thawer is well-suited for food retailer and food processing factory who needs to store fast mass production superchilled thawing frozen food. thin, flat and high value IFQ food products (that normally finished superchilling thawing process by Forced air/blast thawing system, Water sprinkling system, Water Immersion Systems, Vacuum Thawing, Microwave Thawing, Radio Frequency Systems, High voltage electrostatic field (HVEF) thawing).

-

King Son Convertible IFP Superchilling Thawer provides food with an ideal uniformity conditions and environment, where thawing processes and preserves food in controlled constant temperature at -1°C/30.20℉ to -2°C/28.40℉, just below Initial Freezing Point (IFP) of food and 95% high humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% and that embraced in UVC air ventilation bacteriostatic environment which ensures food storage and preservation safety, achieved 3-4 weeks longer shelf life.

-

King Son Convertible IFP Superchilling Thawer Super-chilling thawing process food, the moisture is kept in food, with 95% high humidity storage environment, resulting in minimal dehydration losses and maximum yield.

-

Shorter super-chilling process time than refreezing does again.

King Son Convertible IFP Superchilling Thawer meets the guidance when evaluates superchilling thawing equipment and solutions.

-

a controllable and predictable flow

-

a reproducible superchilling thawing process

-

produce in homogeneous ending-temperature and humidity conditions and envrionment

-

minimizes the weight, drip, and (water soluble) proteins losses

-

optimum and even quality

-

reasonable thawing time to meet thawed quality

-

no environmental impact

-

energy efficient

-

batch process capacity

-

compact design - no space demanding and occupation.

-

flexible running to meet different product size and shape

-

easily to clean, and meet hygienic production demands

-

reliable and safe to operation and running

-

simply and easily to run and maintain

-

No labour intensive and loading

-

low cost investments

-

can run continuously and semi-continuously setup by thawing program

-

easily to fit into food production flow and process

To produce the best superchilling thawed food, King Son Convertible IFP Superchilling Thawer provides an ideal and safe superchilling thawed process and preservation environment where it automatically regulates the controlled temperature, humidity and air velocity, thus creating the optimal conditions for superchilled thawed food with flavor, nutrition, in hygiene, safety, with longer shelf life, reducing food losses and waste, and environment sustainable.