King Son Convertible IFP Lab Chamber Overview

King Son Convertible IFP Lab Chamber Overview

King Son Convertible IFP Lab Chamber is a machinery, plant or laboratory equipment designed for the treatment of materials by a process involving a change of temperature such as cooling and refrigeration for refrigerated food process and beverage preservation.

King Son Convertible IFP Lab Chamber is also a machinery for the preparation of meat or poultry, is a food process and preservation equipment.

King Son Convertible IFP Lab Chamber is a Convertible Temperature Equipment that operates at a chilled, frozen, or variable temperature condition between approximately (6°C/42.8℉ to -12°C/10.4℉), which can display, processes and preserves merchandise and other perishable materials horizontally, semi-vertically, or vertically; with hinged transparent doors; that also has a user adjustable application temperature set point within the operating range of (6°C/42.8℉ to -12°C/10.4℉); and connected to a self-contained condensing unit.

King Son Convertible IFP Lab Chamber is a new refrigeration and food preservation solution for the modern AIoT-era. It is incorporated with A7 Intelligent Food-Tech Controller and designed with Constant Temperature and Humidity Multiple Points Monitoring and Servo Control Technology to perform Convertible Temperature Refrigeration System between precision refrigeration and precision freezing that commercializes five novel next generation refrigeration technologies for food industry by mass production economic scale.

-

King Son Constancy Precision Refrigeration Technology (0°C/32.00℉ to 6°C/42.80℉)

-

King Son Constancy IFP Chilling Technology (0°C/32.00℉ – above Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Technology (-1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Thawing/Tempering Technology (-2°C/28.40℉ to -5°C/23.00℉)

-

King Son Constancy Precision Freezing Technology (-12°C/10.40℉)

that preserves and processes food in uniform conditions and environments, with temperature fluctuations ±0.3°C/0.54℉ and humidity fluctuations ±5%. King Son Convertible IFP Lab Chamber is an AIoT machine which incorporates King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform for remote distance servicing and collaboration – thus helping build new partnership opportunities through IoT eco-system.

King Son Convertible IFP Lab Chamber is designed for precision refrigeration, subzero Food-Tech education and commercial development

King Son Convertible IFP Lab Chamber is designed for precision refrigeration, subzero Food-Tech education and commercial development

-

King Son Convertible IFP Lab Chamber is specifically designed by King Son Constant Temperature and humidity multiple points monitoring and servo control technology to research, develop and performs five novel next generation refrigeration technologies – Precision Refrigeration, IFP Chilling and Superchilling that commercializes emerging food process and preservation methods for food industry, which are developed with Innovation FoodTech, AIoT Technology to increase Nutrition and Shelf Life of food, that achieves mass production industrial Economic value, and energy saving to minimize CO2 emission, and also reduces food loss and waste for environmental Sustainable.

-

The five novel next generation refrigeration technologies, includes

-

King Son Constancy Precision Refrigeration Technology for food process and preservation in Precision Refrigeration method, at (0°C/32.00℉ to 6°C/42.80℉)

-

King Son Constancy IFP Chilling Technology for food process and preservation in subzero IFP Chilling method, at (0°C/32.00℉ – above Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Technology for food process and preservation in subzero Superchilling method, at (-1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Thawing/Tempering Technology for food process and preservation in subzero Superchilling Thawing method, at (-2°C/28.40℉ to -5°C/23.00℉)

-

King Son Constancy Precision Freezing Technology for food process and preservation in freezing method, at (-12°C/10.40℉).

-

-

The five novel next generation refrigeration technologies are designed to produce

-

0.01°C/0.018℉ controlled resolution in constant temperature above/below Initial Freezing Point, with controlled temperature fluctuation ±0.3°C/0.54℉

-

0.1% RH controlled resolution in constant temperature & humidity above/below Initial Freezing Point, with controlled humidity fluctuation ±5% RH.

-

-

King Son Convertible IFP Lab Chamber is a food laboratory testing equipment specifically designed to test, performs and commercializes those novel emerging subzero food process and preservation methods, which can walk out from laboratory to industrial mass production scale by experimental tests.

-

in Precision Refrigeration method, at (0°C/32.00℉ to 6°C/42.80℉) that with temperature fluctuations ±0.3°C/0.54℉ and humidity fluctuations ±5% to keep and hold food freshness and preservation.

-

in subzero, IFP Chilling method, at (0°C/32.00℉ – above Initial Freezing Point of food, without freezing) that with temperature fluctuations ±0.3°C/0.54℉ and humidity fluctuations ±5% to keep food freshness and preservation; and also to increase food value by ripening, aging without freezing.

-

in subzero, IFP Superchilling method, at (-1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point of food) that with temperature fluctuations ±0.3°C/0.54℉ and humidity fluctuations ±5%, in which a thin layer of ice is formed on the surface of food, e.g. the so called crust-freezing, superchilling is used to keep food freshness and for food preservation.

-

in subzero, IFP Superchilling Thawing method, at (-1°C/30.20℉ to -2°C/28.40℉)that with temperature fluctuations ±0.3°C/0.54℉ and humidity fluctuations ±5% to thaw frozen food in superchilling conditions and then temper that to (-2°C/28.40℉ to -5°C/23.00℉) for food temperature equilibrium.

-

in Precision Freezing method, at (-12°C/10.40℉) that) that with temperature fluctuations ±0.3°C/0.54℉ and humidity fluctuations ±5% for food preservation over than one-month

King Son Convertible IFP Lab Chamber provides precision Refrigeration, subzero experiments to research and develop subzero new generation food products

-

King Son Convertible IFP Lab Chamber is suitable for food lab to experiment foods, which are processed and preserved by King Son Novel Food-Techs and analyzed by food testing analyzers, for food shelf life determination, sensory evaluation; and microbiological, biochemical, physiochemical Properties, physical attributes and nutritional analysis, to research and develop new generation food products.

-

Food sensory evaluation

-

Sensory evaluations should be the most important key of your food product development strategy. Reliable, accurate analyses can help with recipe refinement, product development and comparable market research.

-

The sensory evaluation of product quality is very important when it comes to the decision of whether a consumer will buy it again, or if a different product will be chosen.

-

It can be used for quality control, to determine shelf life, to decide whether a new product is worth launching onto the market, for flavor profiling to identify the sensory attributes driving consumer preferences and for taint identification to check if your product is affected by storage or packaging.

-

-

Food chemistry analysis, such as water/moisture content, fat, lipid, protein, ash, pH, salt, minerals, sugar, contaminants, and more.

-

Food chemistry, a major aspect of food science, deals with the composition and properties of food and the chemical changes it undergoes during handling, processing, and storage. Food chemistry is intimately related to chemistry, biochemistry, physiological chemistry, botany, zoology, and molecular biology.

-

-

Food biochemical analysis

-

For example, what and how are biochemical properties, such as of proteins and enzymes, when process and preservation by superchilling?

-

Superchilling is a potential process and preservation method to extend shelf life of food, what and how to thru King Son Convertible IFP Lab Chamber to experiment the storage and preservation degree of superchilling (ice fraction) affects biochemical changes, such as protein denaturation, enzymatic activity and liquid retention is very important, worthy to further experiment and study how the effect of superchilling on biochemical process that influences the quality of juiciness and textural changes.

-

-

-

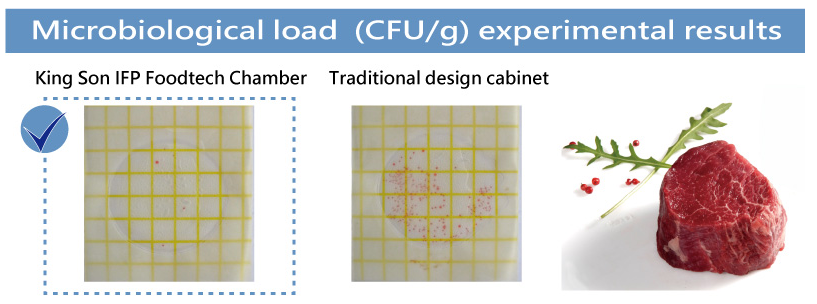

Food microbiology analysis, such as Lactobacillus, Salmonella, Pseudomonas, Listeria, E. coli, Staphylococcus aureus, yeast, mold, and more.

-

Microbiology analysis of food products uses biological, biochemical, molecular or chemical methods for the detection, identification or enumeration of microorganisms in a food. It is often applied to disease causing and spoilage microorganisms.

-

-

Physicals properties analysis

-

What is Physical Testing?

-

Physical testing in the food industry refers to the testing methods used to evaluate various physical properties of a food product. Commonly tested properties of food products include the color, viscosity, weight, thickness, granulation size and texture. Physical testing in the application of food primarily acts as an indicator of quality, but it can also be used for ensuring product consistency. Manufacturers can use this to verify product value, correlate a product with consumer perception and, in some cases, ensure food safety when the product must undergo a cooking step.

-

-

Physicochemical properties are related such as (viscosity, gelation potential, intermolecular association) analysis.

-

-

Food nutrition analysis

-

Nutritional analysis to ensure complying with labelling regulations as well as retailer specifications.

-

For example, to design an experiment to study and analyze the effect of different storage temperature (including precision refrigeration, IFP Chilling and Superchilling) on flavor and ATP-related compounds of meat.

-

To design an experiment to study and analyze the effect of precision refrigeration and IFP Chilling storage temperature on amino acid content, water content, acidity, soluble solids, vitamin C, reducing sugar contents of fruit.

-

-

Food shelf-life studies

-

Shelf life can be defined as the period of time during which a perishable product under a given appropriate set of conditions can be stored or displayed until it is considered as unsuitable for sale or consumption. Shelf life is highly variable among different types of food products and several quality and safety parameters determine its values. These parameters can be divided into the categories of microbiological, chemical and sensory properties.

-

Food shelf life testing

-

Food manufacturers need to accurately determine the use by or best before dates for subzero new generation food products in order to meet strict regulations and to keep their brand and consumers safe.

-

Shelf life is a product of physical, microbiological and chemical processes, triggered by any one of a multitude of contributing factors. Product characteristics, including the quality and consistency of ingredients, the moisture content and acidity levels, all play a part, as do external factors like storage, transport and packaging materials.

-

By performing shelf life analyses, food manufacturers can define accurate dates for the products, ensuring that the quality remains acceptable and safe for consumers.

-

-

-

Food quality control determination

-

Scientifically, quality control of food refers to the utilization of technological, physical, chemical, microbiological, nutritional and sensory parameters to achieve the wholesome food. These quality factors depend on specific attributes such as sensory properties, based on flavor, color, aroma, taste, texture and quantitative properties namely; percentage of sugar, protein, fiber etc. as well as hidden attributes likes. peroxides, free fatty acids, enzyme.

-

The most important element and ultimate goal in food quality control is protecting the consumer. To ensure standardization of these procedures, food laws and regulations cover the related acts affecting the marketing, production, labeling, food additive used, dietary supplements, enforcement of General Manufacturing Practice (GMP), Hazard Analysis and Critical Control Point (HACCP), laws and regulations, factory inspections and import/export inspections.

-

-

Application of emerging food processing technology in the field of biological resources

-

Definition of food processing: Using physical, chemical, microbial fermentation or combined methods to turn and change the original nature, shape, texture of the raw ingredients of agricultural products, livestock products, aquatic products and forest products, that thus increase food preservation and improve and enhance nutritional value, convenience and practicality.

-

Food industry and its manufacturing process

-

It is transformed from a home-grown flavor or a hometown flavor in an agricultural society to food mass production in an industrial society.

-

In food manufacturing process, biological raw materials are treated and processed by physical, chemical, and biological changes, and the purpose is not only to produce food, but also to preserve food in good quality and flavor.

-

-

Three main purposes of food processing and preservation

-

Endow food a longer shelf life and also have the effect of regulating the harvest season.

-

Increasing the added value, improving the properties of raw materials and imparting special flavors, and having marketability for foods.

-

Make effective use of food raw materials and improve the production yield rate by improving the processing technology.

-

-

Emerging food processing technologies & methods: MAP (Modified Atmosphere Packaging) Storage, IFP (Initial Freezing Point) Chilling Preservation, Partial freezing (Superchilling, light-freezing)

-

MAP (Modified Atmosphere Packaging) Storage: Increase carbon dioxide in the modified atmosphere packaging storage, reduce oxygen, increase nitrogen to inhibit fruit breathing.

-

IFP (Initial Freezing Point) Chilling Process & Preservation: between -2°C/28.40℉ and 0°C/32.00℉, (the freezing point of food will drop to -2°C/28.40℉, due to the concentration of food ingredients), maintaining the texture.

-

Superchilling (Partial freezing) Process & Preservation: It is mostly used for the storage and preservation of fish and shellfish. It is not easy to cause protein denaturation by using -3°C/26.60℉.

-

King Son Convertible IFP Lab Chamber is designed with King Son Food-Techs to perform emerging subzero food process and preservation methods for food industry by mass production economic scale

-

King Son IFP Lab Chamber is designed with latest industry AIoT innovations and unique novel next generation refrigeration technology to perform emerging food process and preservation methods, in quality, safety and services.

-

King Son A7 Intelligent Food-tech Controller

-

King Son Constant Temperature and humidity multiple points monitoring and servo control technology

-

King Son Intelligent Temperature Control 3D Dynamic Induction Technology

-

King Son Constant Temperature and Humidity Technology

-

King Son 360° Air Cooling System for uniform temperature distribution in Chamber

-

King Son Smart Defrosting System

-

King Son UVC Air Ventilation Bacteriostatic System

-

King Son Constancy Precision Refrigeration Technology (0°C/32.00℉ to 6°C/42.80℉)

-

King Son Constancy IFP Chilling Technology (0°C/32.00℉ – above Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Technology (-1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Thawing/Tempering Technology (-2°C/28.40℉ to -5°C/23.00℉)

-

King Son Constancy Precision Freezing Technology (-12°C/10.40℉)

-

King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform

-

King Son Constancy Precision Refrigeration Technology, at (0°C/32.00℉ to 6°C/42.80℉) application

-

The relationships between storage parameters, such as temperature or relative humidity, and produce storage life and safety need to be further experiments and studied.

-

The current state-of-the-art house-hold refrigerator design is not optimized to control the temperature and humidity to maintain a high-humidity environment (for vegetable crisper preservation). Most current designs in traditional refrigerator and freezer also rely on vapor-compression systems that are turned ON or OFF at high and low set points, resulting in temperature fluctuations that exceed the lab recommended variation of ±5°C/±9°F). There are limited information available on the relationship between these parameters and food shelf life to drive the rationale for designing truly improved household and commercial refrigeration systems.

-

King Son Constancy Precision Refrigeration Technology is a novel generation Food-Tech after traditional refrigeration and freezing for food process and preservation between 0°C/32.00℉ to 6°C/42.80℉ in controlled constant temperature and humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5%.

-

King Son Constancy Precision Refrigeration Technology is applicable and available to meet when planning conditions for long term preservation a temperature difference of no more than 1°C/32.80℉ in the circulating air should be aimed at, together with a short-term fluctuation of less than 0.5°C/32.90℉.

-

The consequence of fluctuations in temperature often cause condensation or moisture on preservation products, which is undesirable because it may favor the growth of microorganisms, in the case of fruits and vegetables, the growth of mold and the development of decay.

-

King Son Constancy Precision Refrigeration Technology application process

-

Fresh hold, freshness contained

-

Preservation

-

-

Optimum Preservation Conditions for high value crops

-

The recommended conditions for commercial preservation of asparagus are 0°C/32.00℉ to 2°C/35.6℉ with 95 to 99% RH, yielding 14 to 21 days of preservation life. Maintaining a low storage temperature is critical to delay senescence, tissue toughening, and flavor loss. High RH is essential to prevent desiccation and to maintain freshness.

-

Truffles can be kept in good condition for 20 to 30 days at 0°C/32.00℉ with 90 to 95% RH. Preservation life is slightly reduced at 5°C/41.00℉. Attention must be paid to fluctuation of the refrigeration temperature around 0°C/32.00℉ that could freeze truffles and completely destroy their texture.

-

Ginseng should be preserved at 0°C/32.00℉ with 95% RH or higher. Roots retain good quality for 2 months at 0°C/32.00℉.

-

-

The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks

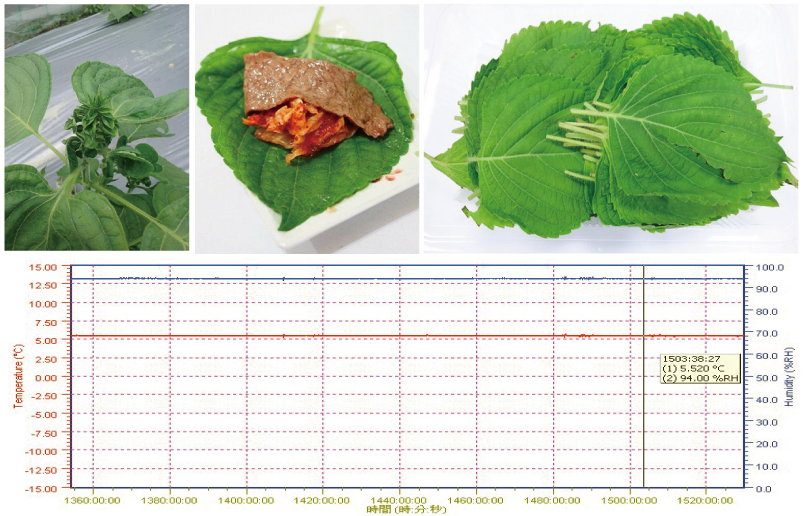

Preserves Korean sesame leaves fresh in King Son Convertible IFP Sub Chiller at 5.5℃/41.90℉, 94% R.H. for 2 months

-

It’s not easily to preserve sesame leaves fresh, since sesame leaves are very sensitive to temperature fluctuation. The best taste time of sesame leaves normally is only 4 days when stores it in traditional refrigerator. It’s very difficult to preserve large volume sesame leaves well and fresh, especially when in harvest season.

-

after several times experiment test in King Son lab, King Son comes out proposal for Korean sesame growers to preserve sesame leaves at 5.5℃/41.90℉, 94% R.H. by King Son Convertible IFP Sub Chiller in which constant temperature fluctuation ±0.3°C/0.54℉, humidity fluctuation ±5% would be the most optimum preservation conditions to keep it well and fresh that extends the best taste time from 4 days to 2 months.

-

The lab graphic chart of temperature curves demonstrated that King Son Convertible IFP Lab Chamber commercializes King Son Constancy Precision Refrigeration Technology with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% to preserves Korean sesame leaves fresh for 2 months that is the core competence Food-Tech innovations developed by King Son for food industry with mass production economic value.

King Son Constancy IFP Chilling Technology in subzero, at (0°C/32.00℉ – above Initial Freezing Point of food, without freezing) application

What is Initial Freezing Point (IFP)?

-

The Initial Freezing Point (IFP) is the temperature in at any fixed pressure at which the liquid and solid phases of a substance of specified composition is in equilibrium. The freezing point of water is 0°C/32.00℉.

-

Foods and beverages do not freeze completely at a single temperature, but rather over a range of temperatures between 0°C/32.00℉ and Initial Freezing Point (IFP). In fact, foods are high in sugar content or packed in high syrup concentrations may never be completely frozen, even at typical frozen food storage temperatures. Thus, there is not a distinct freezing point for foods and beverages, but an initial freezing point at which crystallization begins.

-

The initial freezing point of a food or beverage is important not only for determining the food’s proper storage conditions, but also for calculating thermos physical properties. During storage of fresh fruits and vegetables, for example, the commodity temperature must be kept above its initial freezing point to avoid freezing damage. In addition, because there are drastic changes in the thermos physical properties of foods as they freeze, a food’s initial freezing point must be known to model its thermos physical properties accurately.

-

The initial freezing points of most foods are between -0.5°C/31.10℉ to -2.8°C/26.96℉.

-

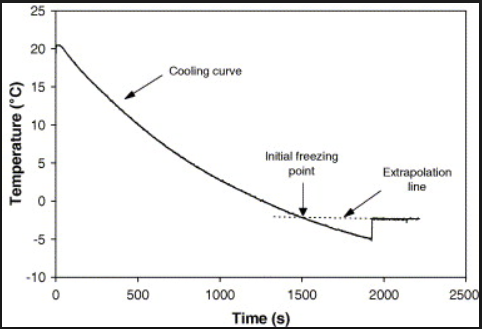

Initial freezing point of Mozzarella cheese

-

Initial freezing points between -1.2°C/29.84℉ and 2.4°C/36.32℉ were observed.

-

The initial freezing point of Mozzarella cheese as shown in Fig. 2 (Fennema et al., 1973)

-

-

Fig. 2. Typical cooling curve of a NaCl 4% w/w solution. Temperature values correspond to the reading of 3 thermocouples.

-

(Source:

-

Gustavo G. Ribero/Initial freezing point of Mozzarella cheese, Journal of Food Engineering 81 (2007) 157–161, page 159

- https://www.sciencedirect.com/science/article/abs/pii/S0260877406006510)

-

What is IFP Chilling?

-

IFP Chilling is the temperature range, defined between 0°C/32.00°F and above Initial Freezing Point (IFP) of food.

-

IFP Chilling temperature can be used to process and preserve fresh fruits, vegetables, meat and fish at a little below 0°C/32.00°F - but above the initial freezing point of food – without freezing, gives food maximum shelf life.

King Son Constancy IFP Chilling Technology commercializes the economic value of the temperature ranges between 0°C /32°F and above Initial Freezing Point (IFP), that performs temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ± 5 % for food preservation in food industry.

-

The effects of King Son Constancy IFP Chilling Technology applied on the fresh food preservation mainly includes

-

King Son Constancy IFP Chilling can inhibit respiration, delay the respiratory peak and reduce the loss of nutrients. The exhaled volume of CO2 in the Constancy IFP Chilling is less than that stored in normal temperature.

-

King Son Constancy IFP Chilling won’t destroy the cells, but improve the quality of fruits and vegetables in the vicinity of freezing temperature. In order to prevent from forming ice, fruits will secrete large amounts of antifreeze (its main ingredients are glucose, amino acids, aspartic acid etc.) to reduce the freezing point, or decompose the starch into sugar. These physiological changes improve the quality of fruits and vegetables in different degrees.

-

King Son Constancy IFP Chilling can inhibit the growth of microbial efficiently. Under the condition of King Son Constancy IFP Chilling, water molecules in fruits or vegetables are arranged in an orderly state, which reduce the content of free water available for the microbial. In the short and mid period preservation, King Son Constancy IFP Chilling can inhibit multiplication of microorganisms, better than the current fluctuated refrigeration temperature.

-

Since King Son Constancy IFP Chilling can inhibit chemical reaction strongly, the food quality in King Son Constancy IFP Chilling is better than that of the current cold storage. The King Son Constancy IFP Chilling also can inhibit lipid oxidation, non-enzymatic and other chemical reaction. The key for the King Son Constancy IFP Chilling preservation is to realize a hibernation state of the product. The “hibernation” process is a cooling process during which the product can reduce its activity ability and energy consumption through the self-adaption, starting from the change of components within cells, and at the same time ensuring their own living life characteristics. It is a typical phenomenon of natural adaption.

-

Food preservation in King Son Constancy IFP Chilling, between 0°C/32.00°F and above Initial Freezing Point (IFP) of food, to prolong shelf life of food

-

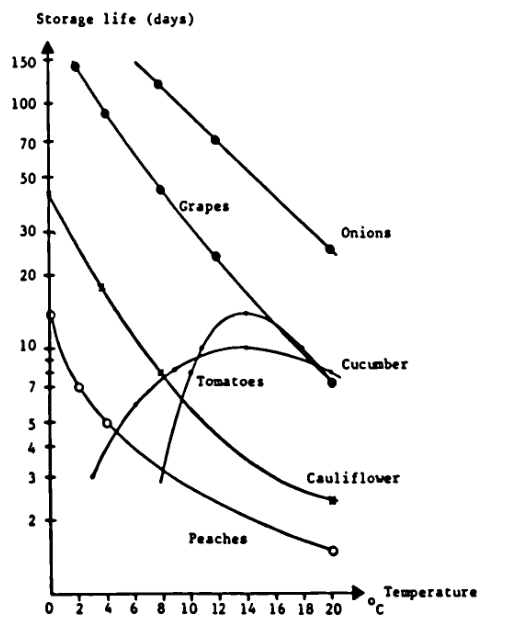

Preserve fresh fruits, vegetables, meat and fish at a little below 0°C/32.00°F - but above the initial freezing point – without freezing, gives food maximum shelf life.

-

-

Figure 3. TTT-curves for some fruits and vegetables.

-

(Source: P. ZEUTHEN et al./ROCESSING AND QUALITY OF FOODS, VOLUME 3, CHILLED FOODS: THE REVOLUTION IN FRESHNESS, page 59

-

IFP Chilling application

-

Fresh hold. freshness contained

-

Preservation

-

Aging

-

Fermentation

-

Rigor off

-

Dehydration

-

Inspissation

-

Case study - dry aging beef above Initial Freezing Point

The study of dry aging pork above Initial Freezing Point

Preserves ice plant by King Son Constancy IFP Chilling Technology between 0°C/32.00°F and above initial freezing point (IFP)

-

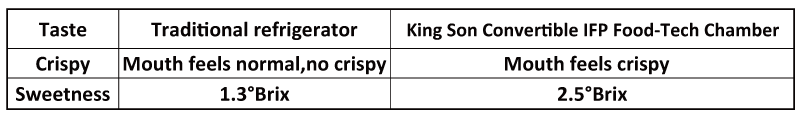

Left picture shown ice plant storage in traditional refrigerator can only keep freshness for 4 – 7 days, sweetness 1.5 °Brix

-

Right picture shown ice plant preserves by King Son Constancy IFP Chilling Technology at the temperature between 0°C/32.00°F and above initial freezing point (IFP), without freezing, that can preserve ice plant freshness for one month, sweetness 5 °Brix.

-

As King Son lab experiment indicated, ice plant preserved in King Son Convertible IFP Sub Chiller benefitted from the ripening process by King Son Constancy IFP Chilling Technology to increases sweetness and also extends the preservation days from 4–7 days to one month, is the best solution for plant factory to preserve large volume ice plant stocks, especially when it is in harvest season.

Preserves vegetables by King Son Constancy IFP Chilling Technology between 0°C/32.00°F and above initial freezing point (IFP) that achieves the effects of lowered down containing Nitrate, NO3

-

To catch up with market development demands and incorporated with modern agriculture technology development that lead farmers to harvest vegetables earlier than past that results vegetables contained more Nitrate, NO3 higher than edible standards.

-

As King Son lab experiments demonstrated that King Son Constancy IFP Chilling Technology preserves vegetables at the temperature between 0°C/32.00°F and above initial freezing point (IFP) that performs the effects of lowered down containing Nitrate, NO3.

-

The Nitrate, NO3 contents of the vegetable before the experiment is 4200ppm, which is reduced to 1500ppm after preservation experiment in King Son Convertible IFP Sub Chiller.

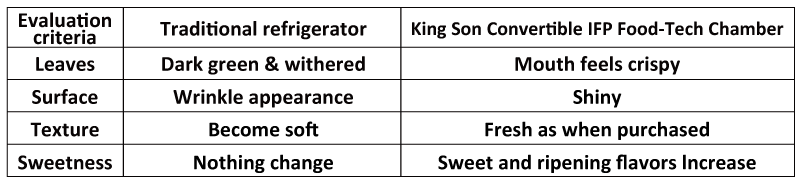

Traditional refrigeratorKing Son Convertible IFP Sub Chiller

Preserves Romaine red leaf lettuces by King Son Constancy IFP Chilling Technology between 0°C/32.00°F and above initial freezing point (IFP)

-

Romaine red leaf lettuces preserves in traditional refrigerator and King Son Convertible IFP Sub Chiller respectively for one week and then compared its freshness, in which the latter preservation method is with better appearance, fresher than the former one stored in traditional refrigeration that proves King Son Constancy IFP Chilling Technology can prolong the days of freshness and extend the shelf life of lettuces.

-

Experiment vegetable: Romaine red leaf lettuce (which is cultivated in King Son Plant Chamber, packed in sealed plastic bag)

-

Experiment days: one week

-

Experiment temperature: 0°C/32.00°F

King Son Convertible IFP Sub ChillerTraditional refrigerator

Preserves cherry tomato by King Son Constancy IFP Chilling Technology between 0°C/32.00°F and initial freezing point (IFP) to prolong freshness to 24 days and thru ripening process to increase sweetness

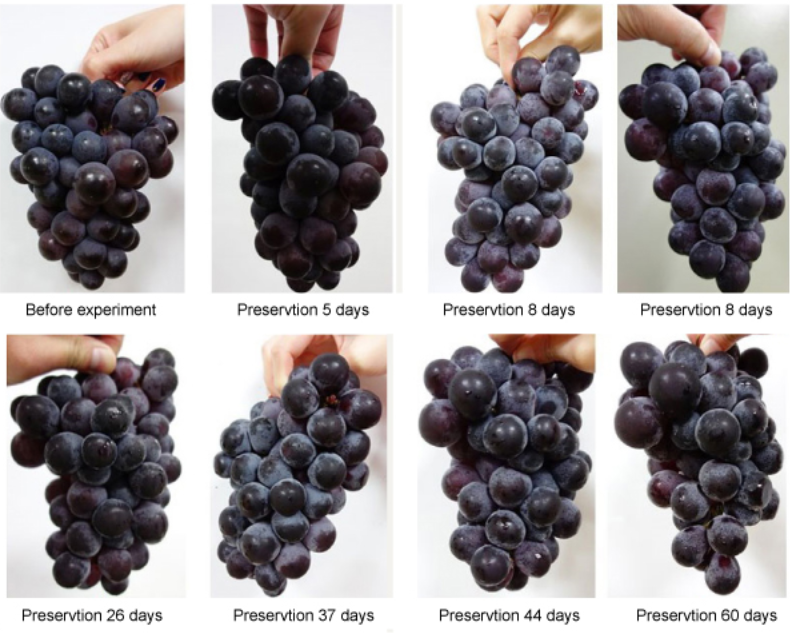

Preserves and ripens grapes in highly humidity conditions by King Son Constancy IFP Chilling Technology between 0°C/32.00°F and above initial freezing point (IFP)

-

Grapes that stores in traditional refrigerator or cold room normally can only maintain freshness for one week. Once over days, grapes will rot away, the taste is deteriorated due to refrigerator’s temperature fluctuation too much that appear cracking and spoiled phenomenon in grapes. In addition to this, the humidity in traditional refrigerator generally is lower that results grapes stem withered, shrivel and wrinkled in appearance.

-

Preserved and ripened grapes by King Son Constancy IFP Chilling Technology at the temperature between 0°C/32.00°F and above initial freezing point (IFP) with high humidity conditions that can effectively prolong grapes freshness longer for 2 months and reduce the fruit loss rate. The grapes retain elasticity and luster appearance after 2 months’ preservation, in which sweetness has improved significantly, the sour is reduced, the flavor is enhanced, due to ripening process.

-

Preserves and ages grapes in highly humidity conditions by King Son Constancy IFP Chilling Technology between 0°C/32.00°F and above initial freezing point (IFP) for 2 months

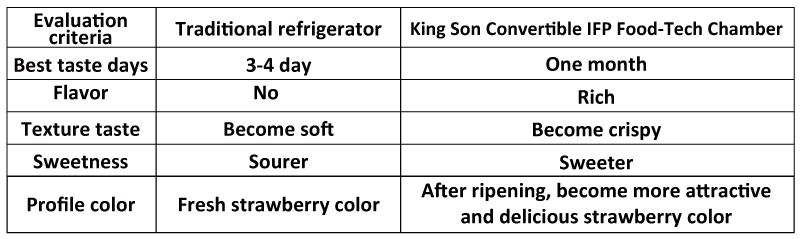

Preserves strawberry by King Son Constancy IFP Chilling Technology between 0°C/32.00°F and above initial freezing point (IFP) to extend the preservation days and thru ripening process to increase flavor

-

Strawberry that stores in traditional refrigerator can only keep freshness for 3–4 days.

-

Preserves strawberry by Constancy IFP Chilling Technology at the temperature between 0°C/32.00°F and above initial freezing point (IFP) that can preserve strawberry freshness and ripening for one month.

Experiment on Different Storage Temperature Impact on Litchi’s Quality Change

-

CFP storage, namely stored the food between 0°C/32.00°F and above freezing point temperature, is a non-frozen preservation, is the third generation of preservation technology following the cold storage and Controlled Atmosphere storage.

-

Through the 35-days experimental study in litchi, it is obvious to see that, compared with the 3°C/37.40℉ storage, the results of CFP storage at -1.2°C/29.84℉, 87% humidity is much better than 3°C/37.40℉ refrigeration storage. During CFP storage litchi’s amino acids content has significantly increase, and the acidity, water content, vitamin C, reducing sugar and soluble solids content change significantly smaller. The study result shows that CFP storage technology can effectively preserve the litchi’s quality and energy, and to achieve the longest shelf life, this has potentially significant implications to the long term storage of litchi, and other vegetables and fruits.

-

(Source:

-

Shen Jiang et al. / Procedia Environmental Sciences 11 (2011) 719 – 725

-

King Son Constancy IFP Superchilling Technology in subzero, at (-1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point of food) application for food process and preservation

What is superchilling?

-

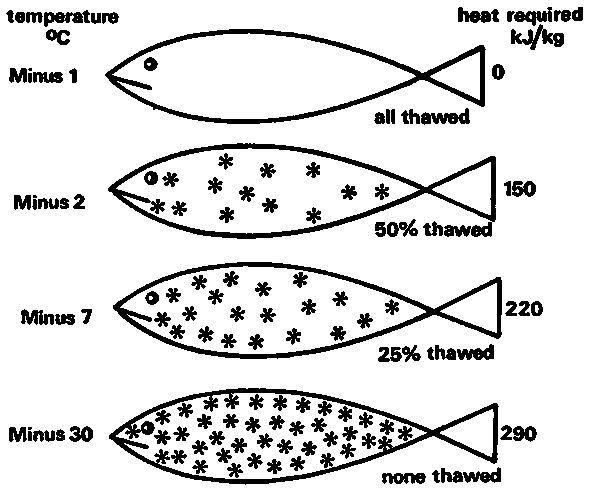

The term ‘superchilling’, is also called partial freezing, light freezing, and deep chilling, which describe a food process and preservation method, where crust freezing, with thin freezing in the outer layer of the food, about 10% to 30% of food's water content is frozen, without complete freezing. During superchilling, the temperature of food is lowered to between -1.5°C/29.30°F to -2°C/28.40°F, below the initial freezing point of food. After initial surface freezing, the ice distribution equilibrates and food obtains a uniform temperature at which it is maintained during preservation.

King Son Constancy IFP Superchilling Technology is designed by King Son Constant Temperature and humidity multiple points monitoring and servo control technology to produce, achieve and perform superchilling conditions that meets the requirements for superchilling process and preservation.

-

0.01°C/0.018℉ controlled resolution in constant temperature above Initial Freezing Point, with controlled temperature fluctuation ±0.3°C/0.54℉

-

0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, with controlled humidity fluctuation ±5% RH.

-

To prevent freeze denaturation of food, superchilling temperature does not fall below the point where freezing is discernible (i.e. -2°C/28.40℉)

-

To avoid low quality influences in the superchilled food, recommended the degree of superchilling (ice fraction) is between 5% and 30% inside the products and that ice fraction larger than 30% inside the product will result in low quality of the food. Therefore, optimal 20 % ice fraction has been recommended.

-

EC Marketing Regulation 1234/2007, Fresh poultry is defined as that which has been kept at temperatures between -2°C/28.40℉ and +4°C/39.20℉

-

USA poultry meat kept above -3.3°C/26.06°F can be marketed as ‘fresh’ (US Poultry products inspection regulations 9CFR381)

-

-

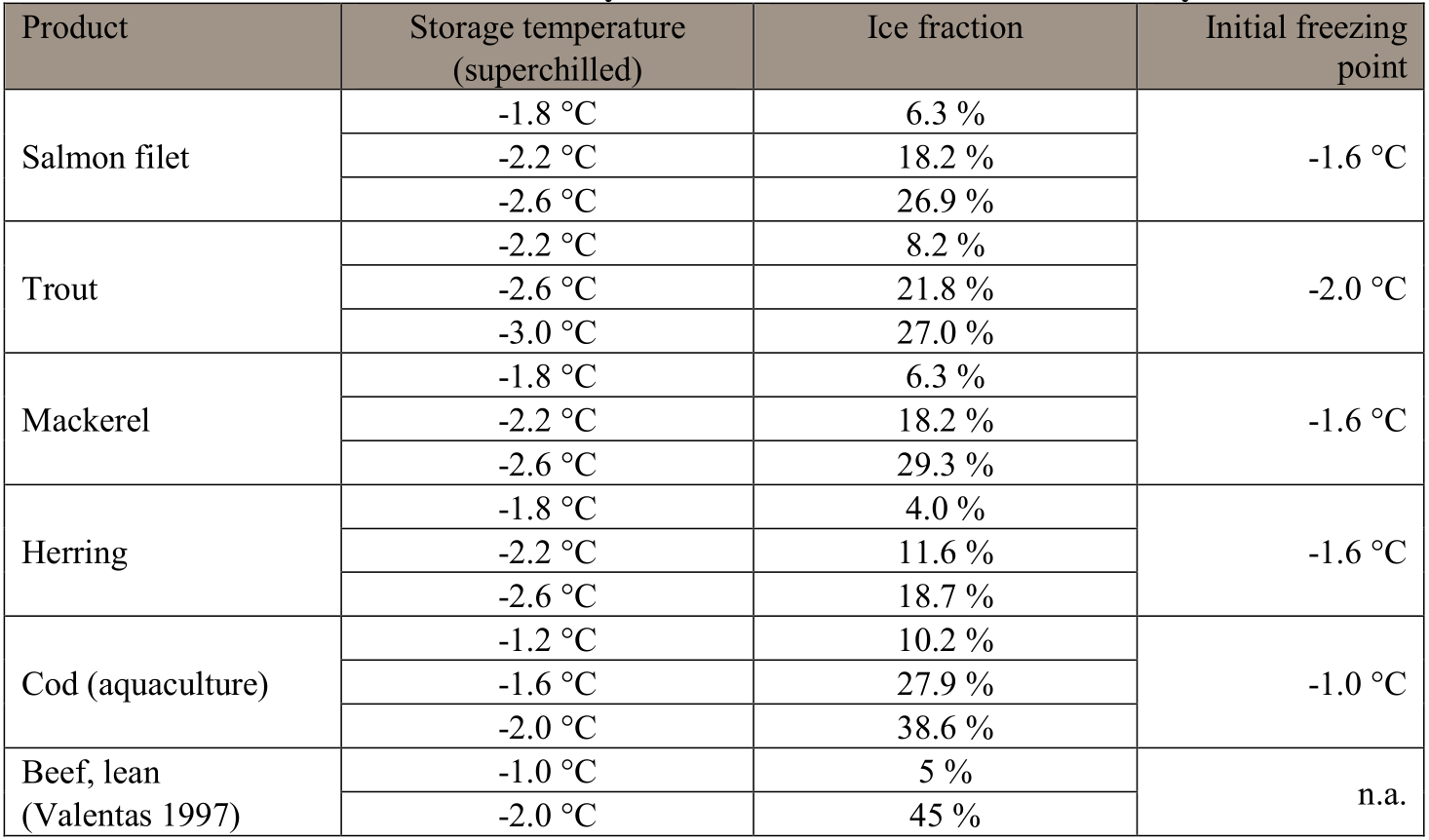

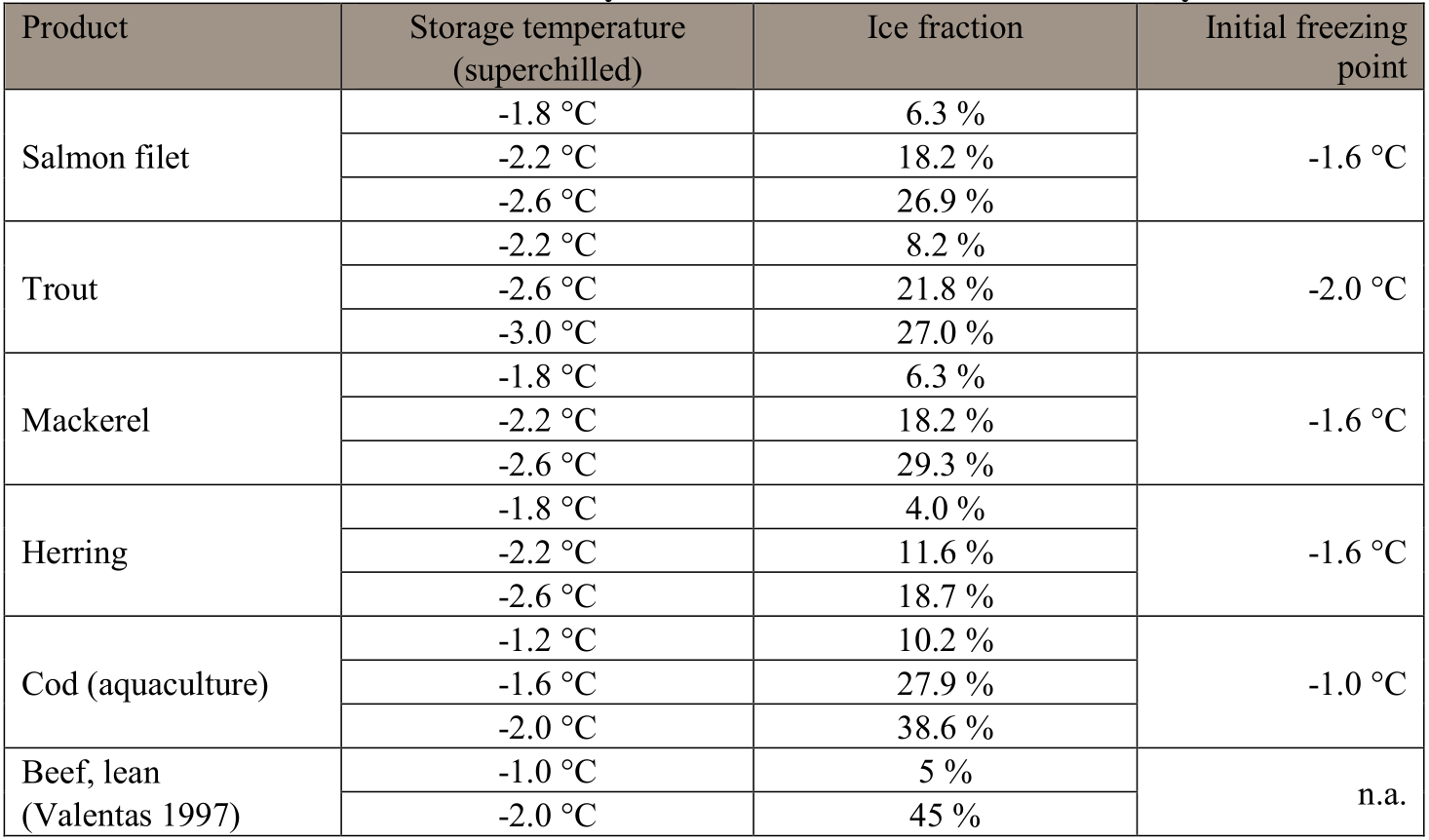

Table 1. Relation between storage temperature and ice fraction for some selected products. Product variations make it necessary to evaluate the ice fraction individually.

-

Michael Bantle et al./ SINTEF Energy Research/ Superchilling of organic food, Part 1: Concept, State-of-the-Art and Potential for small scale implementation, page 15

-

(Source:

-

Figure 1. SUPERCHILLING test at SINTEF, Norway

-

(Source:

-

SUPERCHILLING! A new technology to have your food products fresher than fresh

Why needs superchilling?

-

Fresh foods demand novel refrigeration methods to preserve food products at controlled low temperature through complete cold chain from production, transportation and storage. Storage temperature is important in all stages of the products shelf life, and storage by producer, the retailer and the consumer. The market opinion survey results are fresh foods are better than frozen foods. Therefore, the demand for keeping the food fresh is increasing, and the requirement for keeping the right temperatures are essential. It is therefore important to develop and promote what and how the superchilled products with a low content of ice do have the same quality characteristics as fresh products.

-

Superchilling have great potential to enable safe, high quality and long term storage of foods without the consumer perceived detrimental effects of freezing. Energy and environmental benefits are envisaged due to reduced heat loads and higher storage temperatures (when compared to frozen food).

Superchilling is potential and substantial alternative for freezing

The main efforts now are how to use the experimental research knowledge of superchilling to produce industrial economic scale in the food industry.

In the fast-moving food industry of today, keeping up with the competition is of vital importance. Customers demand better and “newer” products almost every other day, and they also expect affordable prices and high availability. Being able to meet these demands means inventing new food products and using the best technology for processing them and keeping them fresh, tasty and healthy. With decades of product liability testing instrument experiences and as a Food-Tech equipment manufacturer, King Son is able to provide a wide variety of high-quality, state-of-the-art King Son Convertible IFP Food-Tech Chamber for food industry.

King Son Convertible IFP Lab Chamber experiments that proves to commercialize superchilling to process and preserve food for industrial scale economic value

The main efforts now are how to use the experimental research knowledge of superchilling to produce industrial economic scale in the food industry.

In the fast-moving food industry of today, keeping up with the competition is of vital importance. Customers demand better and “newer” products almost every other day, and they also expect affordable prices and high availability. Being able to meet these demands means inventing new food products and using the best technology for processing them and keeping them fresh, tasty and healthy. With decades of product liability testing instrument experiences and as a Food-Tech equipment manufacturer, King Son is able to provide a wide variety of high-quality, state-of-the-art King Son Convertible IFP Food-Tech Chamber for food industry.

King Son Convertible IFP Lab Chamber experiments that proves to commercialize superchilling to process and preserve food for industrial scale economic value

-

King Son Convertible IFP Lab Chamber is a novel generation Food-Tech experiment equipment after traditional refrigerator and freezer, which is designed with King Son Constancy IFP Superchilling Technology to experiment food process and preservation in the temperature of -1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point (IFP) of food, with thin freezing in the outer layer of the food that maintains food freshness to extend shelf-life and retains high food quality and also suppress growth of harmful microbes, in which the controlled constant temperature and humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5 %.

-

After initial surface freezing, the ice distribution equilibrates and food obtains a uniform temperature at which it is maintained during preservation.

-

King Son Constancy IFP Superchilling Technology is designed to produce

-

0.01°C/0.018℉ controlled resolution in constant temperature above Initial Freezing Point, with controlled temperature fluctuation ±0.3°C/0.54℉

-

0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, with controlled humidity fluctuation ±5% RH.

-

-

King Son Convertible IFP Lab Chamber experiments that proves to commercializes the economic value of superchilling at -1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point (IFP), for food process and preservation in food industry.

-

The initial freezing points of most foods are between -0.5°C/31.1℉ and -2.8°C/26.96℉

-

King Son Convertible IFP Superchiller’s application

-

Fresh hold, freshness contained

-

Preservation

-

Thawing

-

Tempering

-

Crust Freezing

-

-

CHAPTER 8 Fahrenheit THERMAL PROPERTIES OF FOODS, Table 3 Unfrozen Composition Data, Initial Freezing Point, and Specific Heats of Foods.

-

CHAPTER 9 Celsius THERMAL PROPERTIES OF FOODS,Table 3 Unfrozen Composition Data, Initial Freezing Point, and Specific Heats of Foods.

-

Case study: King Son Superchilling preservation

-

Case study: King Son Cod fillets 28 days Superchilling preservation

King Son Constancy IFP Superchilling Technology in subzero, at (-1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point of food) thawing application for frozen food process and preservation

King Son Convertible IFP Lab Chamber

-

King Son Convertible IFP Lab Chamber is designed with King Son Constancy IFP Superchilling Technology mainly, specifically designed applied for frozen fish and meat to experiment in thawing process and preserve at -1°C/30.20℉ to -2°C/28.40℉, just below Initial Freezing Point of food, with thin freezing in the outer layer of the food that maintains thawed food to extend shelf-life and retains high food quality and also suppress growth of harmful microbes.

-

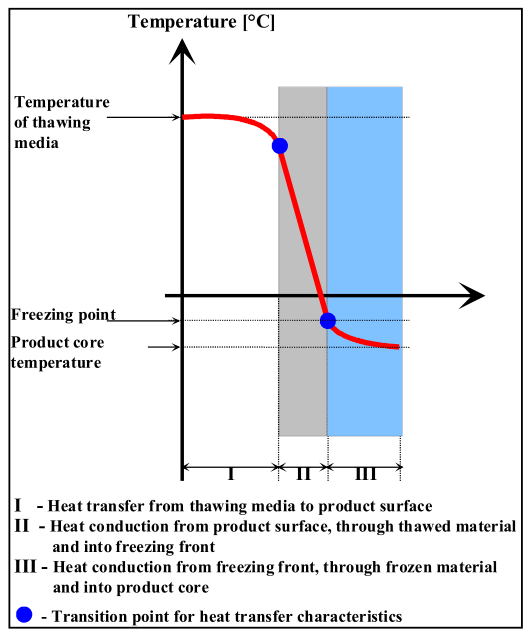

Figure 1. Figure 2.7 Schematic drawing over the three mechanisms of the Convection/conduction thawing principle.

-

(Source: Anders Haugland/INDUSTRIAL THAWING OF FISH - to improve quality, yield and capacity, Chap. 2 Industrial thawing, page 11

-

INDUSTRIAL THAWING OF FISH - to improve quality, yield and capacity

What is thawing?

-

Thawing is the process of changing a product from frozen to unfrozen. It involves transferring heat to a frozen product to melt the ice that was formed within the flesh during the freezing process. The point at which ice crystals are converted back to water occurs completely when the temperature throughout the seafood reaches -1°C/30.20℉. The time required to melt all the ice in the frozen seafood is the thawing time.

Temperature changes during thawing

-

Figure 1 shows the typical temperature changes that occur in foods during freezing and thawing.

-

Figure 1 - Temperature changes during thawing

-

(Source:

-

Seafood thawing, February 2008, Research & Development Department, SR598, page 3, ISBN - 0 903941 99 6

-

The initial rapid temperature rise during thawing is due to the presence of a layer of ice around the food material which forms a protective glaze. This ice glaze layer has a higher thermal conductivity than water and thaws quickly during the early stages.

-

As the surface ice (glaze) melts, the thawing rate slows down and there follows a long period when the temperature of the food is close to that of melting ice. At this time, the energy to overcome the latent heat (i.e. to change the solid ice to liquid water) needs to be overcome. It is also the period where any cellular damage caused by, for example, poor handling before freezing, excessively slow freezing or poor temperature controls, result in the release of cell constituents to form ‘drip losses’.

-

Commercially, foods can be thawed to just below the freezing point to retain a firm texture for subsequent processing. This process is known as tempering.

-

(Source:

-

Seafood thawing, February 2008, Research & Development Department, SR598, page 3, ISBN - 0 903941 99 6

-

Some facts about fish thawing

-

Thawed fish spoil as rapidly as wet fish, and must be kept chilled until required; the thawed fish can be iced, or the fish can sometimes be removed from the thawer just before thawing is completed, so that the fish has its own small reserve of cold.

-

Fish will normally lose some weight on thawing; this drip loss may amount to up to 5% for properly frozen and cold stored white fish, though it can be considerably more if insufficient attention is paid to thawing procedure. Very little, if any, of this loss is directly attributable to the thawing process itself; some is accounted for by changes in the nature of the flesh during cold storage, some is due to the melting of any glaze that has been coated onto the fish. Fish that have been frozen before the onset of rigor may complete the rigor process after thawing if the changes have not already taken place gradually during cold storage; this effect is usually more obvious with fillets than whole fish, the fillets contracting noticeably in length. It may be necessary to thaw pre-rigor fillets slowly in order to avoid distortion or shrinkage.

-

-

(Source:

-

FAO CORPORATE DOCUMENT REPOSITORY, produced by: Torry Research Station, Title: Thawing frozen fish

-

INDUSTRIAL SUPERCHILLING THAWING Application for FISH - to improve quality, yield and capacity

-

The Norwegian quality regulation for fish and fish products demand that the thawing should be finalized as soon as the coldest part of the product reached -1°C/30.20℉, and there should be no delay in the further processing. Each shift should process the fish thawed within the same shift, and thawed fish should if necessary be iced in order to give the product a temperature of 0°C/32.00°F.

-

(Source:

-

Anders Haugland/ INDUSTRIAL THAWING OF FISH - to improve quality, yield and capacity, Chap. 2 Industrial thawing, page 27

-

-

King Son Convertible IFP Superchilling Thawer plays a key experiment role for superchilling thawing value chain

-

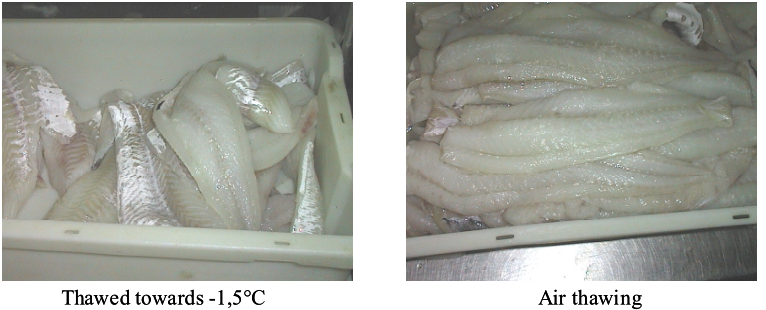

Figure 5.22 The trimmed fillets after thawing. RSW thawed towards -1.5°C/29.30℉ vs. Air blast thawed product.

-

(Source: Anders Haugland/ INDUSTRIAL THAWING OF FISH - to improve quality, yield and capacity, Chap. 5 Thawing of lean fish – Cod, page 135

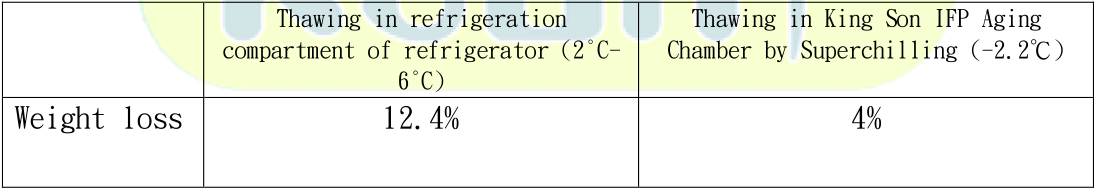

King Son Superchilling Thawing experimental test results:

-

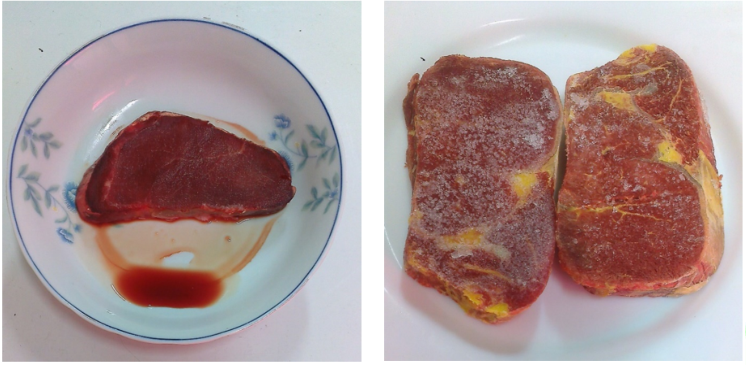

Thaws frozen beef in King Son Convertible IFP Superchilling Thawer (-2.2°C/28.04℉) and refrigeration compartment (2°C/35.6℉ to 6°C/42.80℉) of refrigerator for 24 hours, the weight loss as below:

-

Learned from above experiment results that Thaws frozen beef by Superchilling (-2.2°C/28.04℉) in King Son Convertible IFP Superchilling Thawer can minimize the weight loss of thawing. The pictures as below shown the actual thawing status of frozen beef.

-

The picture in upper left is the frozen beef thawed 24 hours in refrigeration compartment (2°C/35.6℉ to 6°C/42.80℉ that shows a lot of drip loss, this result evidences that frozen beef thawed in the refrigeration compartment of refrigerator can cause irreversible damage to the food tissues, resulting in a significant drip loss and mouthfeel deterioration, which in turn causes food nutritional value down and high weight loss.

-

The picture in upper right is the frozen beef thawed 24 hours in King Son Convertible IFP Superchilling Thawer that shows no drip loss by Superchilling (-2.2°C/28.04℉), there is only a very thin ice on the surface of beef which is still pliable and yields to the thumb when pressed, evidences that the beef is ready to process after finished thawing. Most consumers consider a product to be fresh, as opposed to frozen, when it is pliable or when it is not hard to the touch.”

-

In order to further observe whether the thawing in Superchilling performed by King Son Convertible IFP Superchilling Thawer that cause damages to food tissue or not, the Superchilling thawing beef (shown in upper right picture) is placed at room temperature for 30 minutes and the results are shown below:

-

Above actual photo shows that there is no drip loss happened after the Superchilling thawing beef acclimated to room temperature, this results evidences that the Superchilling Thawing process in King Son Convertible IFP Superchilling Thawer is hardly to produce impacts on food tissue that preserves food’s original nutrients and keep the taste same.

-

Conclusion

-

Thaws frozen food by Superchilling temperature (-2.2°C/28.04℉) in King Son Convertible IFP Superchilling Thawer can minimize the weight loss of thawing. The traditional thawing method, due to the temperature difference is too large and the temperature fluctuation too much, easily lead to the food tissue damages in the thawing process and make food taste worse, and cause a lot of drip loss and nutrient disappeared.

-

King Son Convertible IFP Superchilling Thawer can provide frozen food thawing in Superchilling, at above 85% constant high humidity environment that minimizes the weight loss in thawing process, it is hardly to produce impacts on food tissue and preserves food’s original nutrients and keep the taste well after finished thawing.

-

By what and How King Son Convertible IFP Lab Chamber does subzero food process and preservation in experiment? Why choose King Son for best subzero experimental test solutions?

-

IFP Chilling process and preservation

-

Food is chilled to above its initial freezing point of food, without freezing for IFP Chilling storage and preservation

-

-

Superchilling process and preservation

-

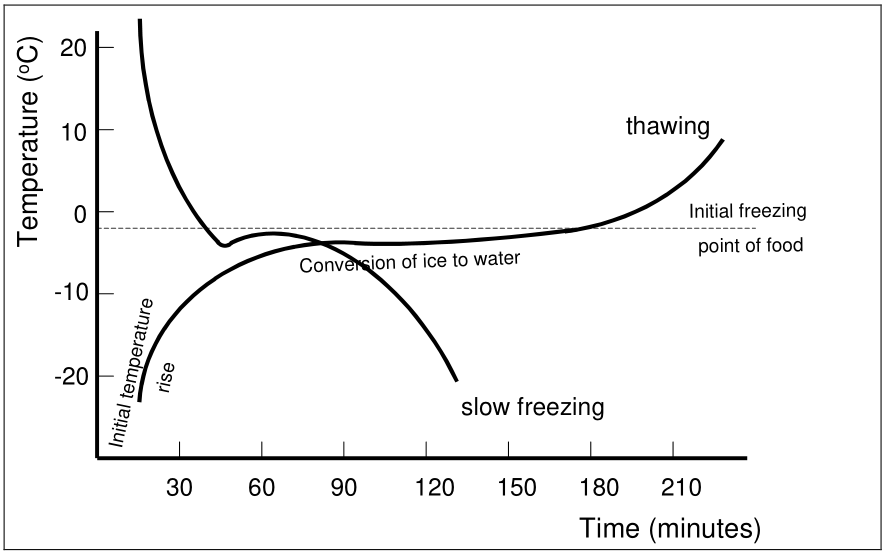

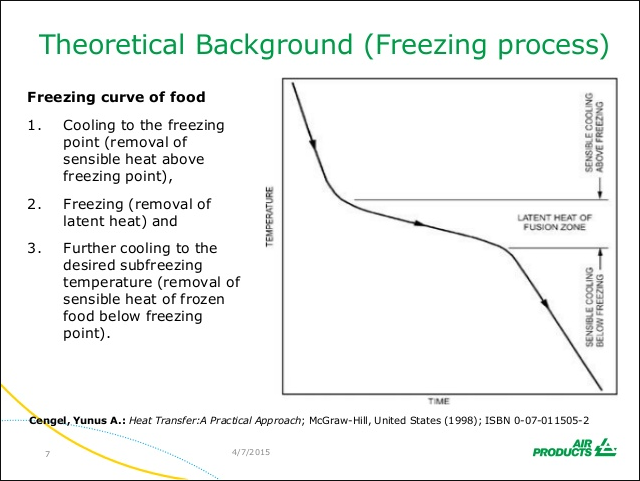

The superchilling technology can be divided to two stages – superchilling process and superchilled storage/preservation.

-

Stage 1, superchilling process: food is superchilled to its initial freezing point of food;

-

Stage 2, superchilled storage: by removing the latent heat of crystallisation in the food for superchilled storage

-

-

In superchilling process stage, food is superchilled by pre-cooling function in King Son Convertible IFP Lab Chamber to below its initial freezing point of food so that the latent heat of crystallization can be removed firstly and then forms ice nuclei. The heat removal rate and the numbers formed ice nuclei depends on the temperature difference between the cooling media and the product.

-

-

Freezing curve of food

-

(Source:

-

Cengel, Yunus A.: Heat Transfer: A Practical Approach; McGraw-Hill, United States (1998), ISBN 0-07-011505-2

-

Randy Peterson/Process Freezing 101: 4 Variables Food Processors Must Understand,Part 1: Process freezing series

-

-

Why choose King Son for the best next generation emerging precision refrigeration, subzero storage and preservation solutions?

-

King Son Convertible IFP Lab Chamber provides food ideal precision refrigeration, subzero process condition and preservation environment.

-

Precision refrigeration, Subzero process and preserve food naturally and safely in King Son Convertible IFP Chamber.

-

King Son Convertible IFP Lab Chamber monitors and controls precision refrigeration, subzero controlled factors.

-

King Son Convertible IFP Lab Chamber provides UVC Air Ventilation Bacteriostatic System for antibacterial and microbiological control.

-

King Son Convertible IFP Lab Chamber is available to preserves food in Superchilling.

-

King Son Convertible IFP Lab Chamber provides food constant precision refrigeration, subzero preservation conditions and environments

-

King Son Convertible IFP Lab Chamber provides food with an ideal uniformity conditions and environment, where processes and preserves food in convertible controlled constant temperature at

-

(0°C/32.00℉ to 6°C/42.80℉), precision refrigeration

-

0°C/32.00℉ - above initial freezing point of food, IFP Chilling

-

-1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point (IFP) of food, Superchilling

-

-1°C/30.20℉, Superchilling thawing

-

-10°C/14.00℉ to -20°C/-4.000℉, tempering

-

and 95% high humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% and that embraced in UVC air ventilation bacteriostatic environment which ensures food storage and preservation safety.

Precision refrigeration, subzero process and preserve food naturally and safely in King Son Convertible IFP Lab Chamber

Precision refrigeration, subzero process and preserve food naturally and safely in King Son Convertible IFP Lab Chamber

-

Precision refrigeration, subzero is a new method preserved food fresh for a whole month, without the use of chemical additives, examples include salt in water, alcohol in water, or the mixing of two solids such as impurities in a finely powdered drug.

King Son Convertible IFP Lab Chamber monitors and controls precision refrigeration, subzero process and preservation factors

-

Temperature, with fluctuation ±0.3°C/0.54℉

-

Temperature fluctuation affects food quality and safety.

-

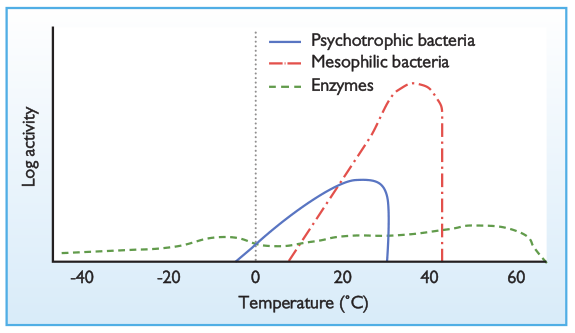

It is well known that both enzymatic and microbiological activity are greatly influenced by temperature that temperature changes have greater impact on microbiological growth than on enzymatic activity for food safety.

-

-

Figure 2. Relative enzyme activity and microbial growth rate in relation to temperature (Andersen et al., 1965)

-

(Source:

-

The evolving story of fish shelf-life management, International Meat Topics — Volume 1 Number 1, Page 1,

-

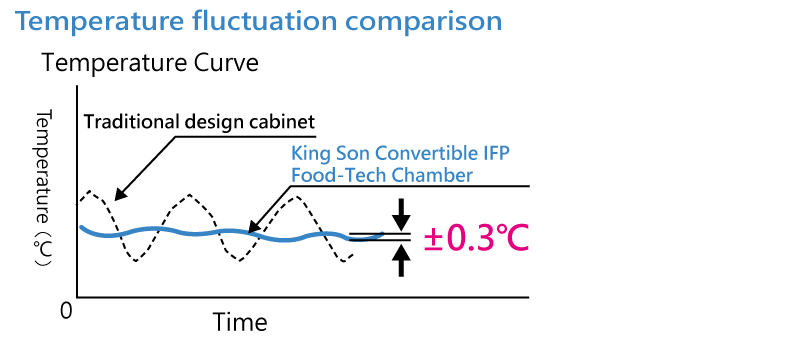

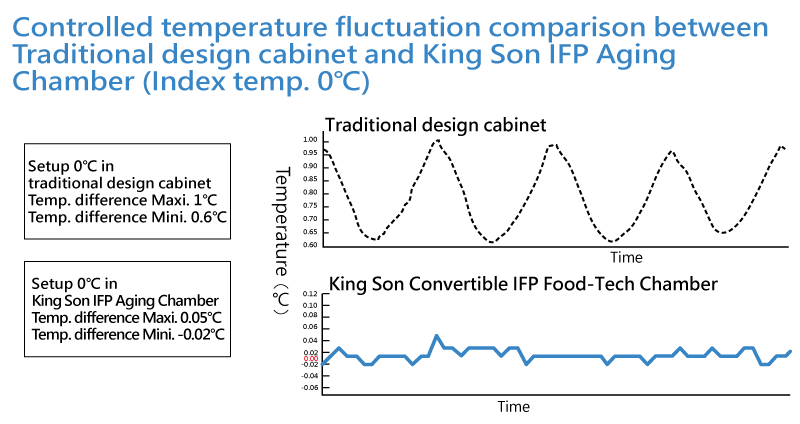

To eliminate temperature fluctuation impacts on food quality and safety, King Son researched, developed and launched King Son Constancy IFP Superchilling Technology in 2015 that provides a unique constant temperature stability ±0.3°C/0.54℉, which reduces the traditional temperature fluctuation from ±5°C/9℉ down to ±0.3°C/0.54℉.

-

Most current designs in traditional refrigerator and freezer also rely on vapor-compression systems that are turned ON or OFF at high and low set points, resulting in temperature fluctuations that exceed the recommended variation of ±5°C/9℉.

-

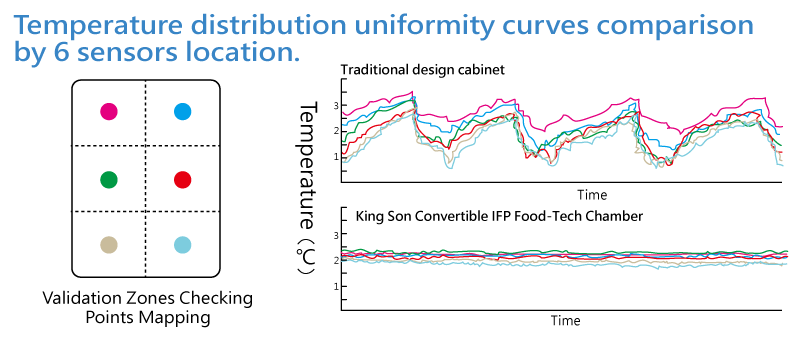

Non uniformity temperature distribution in the traditional cabinet is the main reason produced food waste.

-

In addition, when process by superchilling, it should also be noted that reducing temperature variations to a minimum extent during subzero storage is of great importance. Minor temperature changes may lead to ice melting and recrystallization, thus changing the size and distribution of ice crystals inside food, and increasing the amount of myofiber detachment or breakage during storage, eventually resulting in drip loss after thawing. Therefore, keeping a stable temperature is critical for reducing drip loss during subzero storage and preservation.

-

King Son Convertible IFP Lab Chamber is a flexible and effective subzero storage and preservation equipment that can meet the demands and fulfill the requests of more research on how to control and keep the required storage temperature after initial surface freezing. The subzero preservation temperature should be stable enough to avoid significant levels of ice crystal growth that can cause structural damage during the storage of the subzero product as well as to keep the degree of subzero within a narrow margin.

-

95% Related Humidity, with fluctuation ±5%

-

The amount of humidity should be monitored closely, because too much will allow disproportionate microbial growth, whereas too little will cause excessive shrinkage.

-

The humidity of the preservation conditions should be over 90 percent and the air velocity should be low to minimize food dehydration.

-

King Son Convertible IFP Lab Chamber is designed to produce 0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, and controlled humidity fluctuation ±5% RH.

-

-

Air velocity

-

It is equally critical since it acts as a medium for moisture removal from the superchilled area. Inadequate air velocity will permit undue moisture to condense on the product, and as a result, off-flavors and aromas, as well as spoilage, will occur. On the other hand, if the air velocity is too high, this will result in excessive surface drying, with resulting weight and trim losses.

-

King Son Convertible IFP Lab Chamber is incorporated with 360° Air Cooling System, it is a unique design of the wind field, thru that cooling air inputs into to the chamber that produces uniform temperature distribution, so that cooling is more stable, efficient and allows for accurate temperature distribution uniformity inside the chamber.

-

Temperature distribution uniformity curves comparison by 6 sensors location

-

King Son Convertible IFP Lab Chamber provides UVC Air Ventilation Bacteriostatic System for antibacterial and microbiological control

-

The use of ultraviolet (UV) light to eliminate bacterial cells is well known for fresh meat. A more sophisticated approach to manage the subzero process and preservation is to install UV. Air is through the sealed UV channel to circulate in the subzero process zone of the chamber.

-

King Son UVC Air Ventilation Bacteriostatic System remove the micro-organisms in the chamber enables a safe subzero food process and preservation environment.

King Son Convertible IFP Lab Chamber preserves food in Superchilling temperature

-

Once finished subzero process, King Son Convertible IFP Lab Chamber can switch the process mode to superchilling preservation that preserves food in superchilling (-1.5°C/29.30°F to -2°C/28.40°F), with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% which extends the shelf life of the meat for 3 – 4 weeks.

-

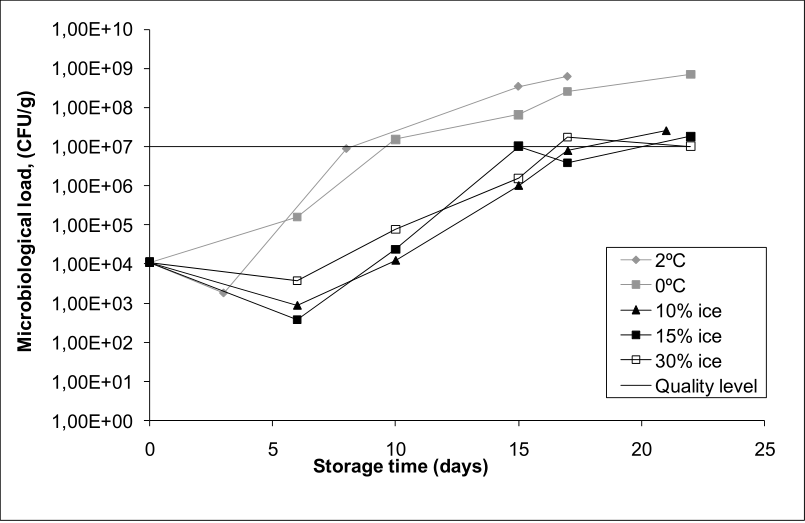

The aim of superchilling is to preserve food products at temperatures just below their initial freezing point; low enough to substantially reduce bacterial activity but high enough to avoid significant levels of bigger size ice crystal growth as frozen does that can cause food structural damage.

-

The quality limit of 107 CFU/g represents a usual microbiological quality measure, above which food is regarded as unfit for human consumption.

-

Figure 3. Microbiological load (total count) for unpacked chilled and superchilled salmon fillets

-

(Source:

-

Stevik, A.M. 2007. Microbiological level of unpacked, chilled and superchilled salmon fillets. In SINTEF Energy Research, Trondheim

-

Case study: King Son Superchilling preservation

-

Case study: King Son Cod fillets 28 days Superchilling preservation

King Son Convertible IFP Lab Chamber Can Perform Collaboration Experiments Application with sub chilling system and impingement freezer to realize IFP Chilling/Superchilling Cold Chain value and efficiency

-

The superchilling technology can be divided into two stages – superchilling process and superchilled storage/preservation. The whole process of superchilling/deep chilling can be further divided into two stages: (1) In the first stage (pre-cooling stage), the product is cooled to its initial freezing point followed by (2) removing the latent heat of crystallisation (phase transition stage) in the second stage (Kaale and Eikevik 2013).

-

The superchilling process, a highly transient process (for example, in 2 – 4 minutes by Impingement freezer), that is usually performed by Mechanical freezer, Cryogenic freezer, or Impingement freezer as freezing samples at a very low temperature (-20°C/-4.000℉ to -30°C/-22.00℉) but then storing samples at a higher temperature (superchilling storage temperature,-1.7°C/28.94℉± 0.5°C/0.9℉), which develops large thermal gradient near the surface of the product. This gradient causes slight melting of small ice crystals formed at the surface layer, and subsequent water diffusion to large ice crystals at the surface layer of the superchilled food during superchilling storage and preservation. Thus, controlling temperature stability in superchilling procedure is one of the most importance terms.

-

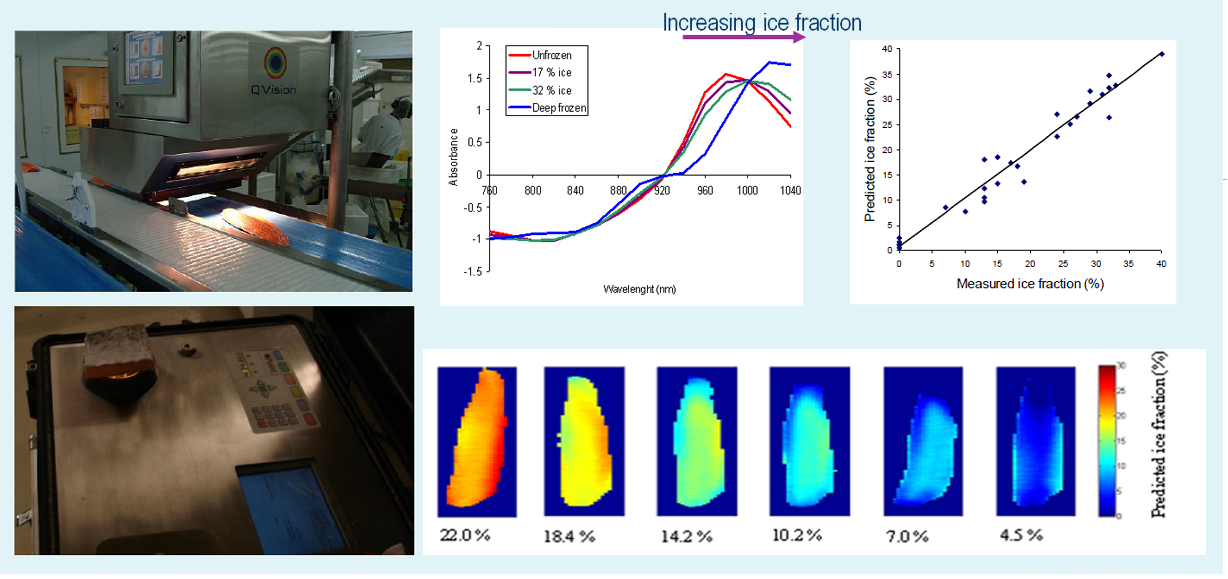

In practice, controlling and measuring temperature must be performed after pre-chilling and temperature equilibrium processes completion. Accurate temperature measurements can be carried out under laboratory conditions, but under industrial conditions one cannot expect to improve an accuracy of ± 0.5°C/0.9℉. And even with this accuracy, how to measure the amount of ice crystals (ice fraction or degree of superchilling) accuracy and timely in the product is the other extremely challenge for the strong dependency of ice content on the temperature during superchilling process (Magnussen et al., 2008).

-

Optimum superchilling storage and preservation temperature

-

To optimize physicochemical properties of food during superchilling processing and preservation is very important in superchilling research and development.

-

Superchilling storage temperature fluctuation is especially vulnerable due to the irreversible changes that happens in the food, in which ice crystallization can lead to cell destruction or puncturing of membranes as well as protein denaturation, leading to loss of water holding capacity and increased drip loss. Also when some of the water freezes out, the concentration of solutes in the unfrozen solution increases. “This may lead to increased enzymatic activity, protein denaturation and structural damage of membranes, resulting in increased drip as well as loss in water holding capacity and textural changes (Foegeding and others, 1996). Good thermal control during superchilling is therefore necessary to ensure high product quality".

-

-

King Son Convertible IFP Lab Chamber is a flexible and effective Superchilling storage and preservation equipment that can meet the demands and fulfill the requests of more research experiments on how to control and keep the required constant storage temperature after initial surface freezing. The Superchilling preservation temperature should be stable enough to avoid significant levels of ice crystal growth that can cause structural damage during the storage of the superchilled product as well as to keep the degree of superchilling within a narrow margin.

-

King Son Convertible IFP Lab Chamber provides food with an ideal uniformity conditions and environment, where test, processes and preserves food in controlled constant temperature at -1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point (IFP) of food and 95% high humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% and that embraced in UVC air ventilation bacteriostatic environment which ensures food storage and preservation safety, achieved 3-4 weeks longer shelf life.

King Son Convertible IFP Lab Chamber is a designated ‘plug-and-play’ production unit for small-sized food processors who need a cost-effective method to chilling, crust freezing and super-chilling their food before process operations.

King Son Convertible IFP Lab Chamber is designed for mechanical freezing process to experiment and treat food crust freezing and super-chilling process at standard speeds.

-

Batch superchilling by mechanical freezing method to experiment, process and preserve thin or flat products, including high-value individually quick-frozen (IQF) products.

-

Batch crust freezing experiment to test the stability of soft food and confectionery by mechanical freezing method before further processing.

-

Improve throughput, yield and hygiene for delicious product in slicing process operation.

-

Batch superchilling experiment the raw meats by mechanical freezing method for safer chilled storage, preservation and distribution.

-

Food types available application

-

Meat

-

Poultry

-

Sea food

-

-

King Son Convertible IFP Lab Chamber plays a key experimental role in the final stage(s) of the IFP Chilling and Superchilling value chain

-

The IFP Chilling and Superchilling value chain can be realized in existing production facilities by implementing setup a commercial blast freezer. Therefore, it is easily to produce IFP Chilled and Superchilled products. However, IFP Chilling and Superchilling storage requires a new design for existing storage and refrigeration systems to ensure and control the temperature fluctuation and achieve uniform distribution in the storage space.

-

Most current designs in traditional refrigerator and freezer also rely on vapor-compression systems that are turned ON or OFF at high and low set points, resulting in temperature fluctuations that exceed the lab recommended variation of ±5°C/±9°F). When superchilled products exposed to such temperature fluctuations, it will result thawing and re-freezing of the ice inside the food that leads have a poor impact on the product quality and stability.

-

Benefiting high-volume impingement freezer producers requiring rapid superchilling processes in food processing factory. King Son Convertible IFP Lab Chamber experiment results serves as a superchilling storage and preservation solution for superchilled foods in retailers operating in the final stages of superchilling value chain.

-

Figure 4. Shell (crust) freezing of pork neck in impingement freezer for superchilling.

-

(Source: Superchilling and supercooling

-

King Son Convertible IFP Lab Chamber experiment results proved that it is well-suited for food retailer and food processing factory who needs to store fast mass production superchilled thin, flat and high value IFQ food products (that normally finished crust freezing, superchilling process by blast chiller, Mechanical freezer, Cryogenic freezer and Impingement freezer).

-

King Son Convertible IFP Lab Chamber provides food with an ideal uniformity conditions and environment, where test, processes and preserves food in controlled constant temperature at -1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point (IFP) of food and 95% high humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% and that embraced in UVC air ventilation bacteriostatic environment which ensures food storage and preservation safety, achieved 3-4 weeks longer shelf life.

-

King Son Convertible IFP Lab Chamber Super-chilling process food surface, the moisture is kept in food, with 95% high humidity storage environment, resulting in minimal dehydration losses and maximum yield.

-

Shorter super-chilling process time than freezing does.

-

Case study: King Son Cod fillets 28 days Superchilling preservation

King Son Convertible IFP Lab Chamber Can Perform Collaboration Experiment Application with Commercial Blast Chiller to Process, Preserve and Maintain the Quality of Cook-Chill or Cook-Freeze Foods

-

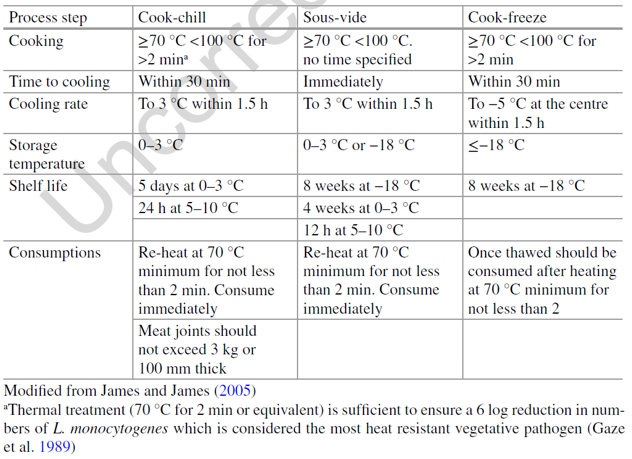

The cook-chill system is a preservation technology where food is fully cooked at usually <100°C/212.0℉ and then food is subsequently chilled rapidly and stored under controlled conditions where the final core temperature is maintained above the freezing point, at 0°C/32.00°F to -3°C/26.60℉.

-

Now “superchilling preservation” are being used to extend the shelf-life of food by maintaining food’s storage temperature at -1°C/30.20℉ to 2°C/35.60℉, below freezing temperature.

-

Superchilling could increase the shelf-life of cook-chill.

-

Cook-freeze foods are treated and processed the same way as cook-chill foods, but the final food product is either super-chilled (that cooled and maintained at 1°C/32.80℉ to 2°C/35.60℉ below the freezing point of food) or frozen-chilled (that frozen at a temperature of below -30°C/-22.00℉ and then thawed to 5°C/41.00℉ when needed).

-

Table 7.1 Processing requirements and shelf life of cook-chill, sous-vide and cook-freeze products

-

(Source:

-

Atef Elansari et al./Processing, Storage and Quality of Cook-Chill or Cook-Freeze Foods

-

What is cook chill? What is King Son Cook IFP chilling preservation method?

-

A food preservation method in which it is prepared and portioned, cooked, and then either chilled by commercial blast chiller to

-

3°C/37.40℉ in a central kitchen. Cook-chill preserves food for up to four days before it is reheated for eating, or

-

IFP Chilling temperature, between 0°C/32.00°F and above IFP (initial freezing point) of food, without freezing it, and then preserving it in King Son Convertible IFP Lab Chamber for over than four days to 2-3 weeks, before it is reheated for consumption.

-

The methodology – King Son Cook IFP chilling preservation method is simple to do, all it needs is a standard blast chiller that current mechanical refrigeration techniques are well able to rapidly chill cooked food to IFP Chilling temperature, at between 0°C/32.00℉ and above IFP (initial freezing point) of food, without freezing, and then, to preserve cooked foods, transfer in King Son Convertible IFP Lab Chamber by King Son Constancy IFP Chilling Technology for longer shelf life, with IFP Chilling 2 – 3 weeks storage, before it is reheated for eating (no thawing needed).

-

What is cook freeze? What is King Son Cook IFP Superchilling preservation method?

-

A Food preservation method in which it is prepared and portioned, cooked, and then either chilled by commercial blast chiller to

-

Frozen to -20°C/-4.000℉ in a central kitchen. Cook-freeze preserves food for up to eight weeks before it is reheated for eating, or

-

Superchilling temperature, at -1.5°C/29.30°F to -2°C/28.40°F, below initial freezing point of food, with thin freezing in the outer layer of the food, and then preserved in King Son Convertible IFP Lab Chamber for 3 - 4 weeks. Has advantage of thawing more quickly, before being reheated for consumption.

-

The methodology – King Son Cook IFP Superchilling preservation method is simple to do, all it needs is a standard blast chiller that current mechanical refrigeration techniques are well able to rapidly superchill cooked food to IFP Superchilling temperature, at -1.5°C/29.30°F to -2°C/28.40°F, below initial freezing point of food, and then, to preserve cooked foods, transfer in King Son Convertible IFP Lab Chamber by King Son Constancy IFP Superchilling Technology for longer shelf life, with IFP Superchilling 3 – 4 weeks storage. As stated, has advantage of thawing more quickly, before being reheated for consumption.

-

Superchilling can safely extend the shelf life of cook-chill prawns by 120%

-

Superchilling could increase the shelf life of cook-chill prawns to 22 days. This offers a potential 120% increase on the 10-day chilled shelf life subject to the protocol being implemented commercially.

-

Extending the shelf-life of meat and fish products with superchilling

-

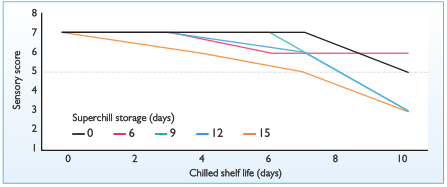

Fig. 1. Chilled sensory shelf life of prawns after 0, 6, 9, 12 and 15 days of superchill storage. Shelf life is deemed to end when sensory score = 5.

-

(Source:

-

by Greg Jones, Microbiologist, Campden BRI, Station Road, Chipping Campden, Gloucestershire GL55 6LD, UK.

-

International Meat Topics — Volume 6 Number 5, http://www.positiveaction.info/pdfs/articles/mt6_5p20.pdf)

To produce the best subzero food, King Son Convertible IFP Lab Chamber provides an ideal and safe subzero process and preservation environment where it automatically regulates the controlled temperature, humidity and air velocity, thus creating the optimal conditions for subzero food in fresh, with flavor, nutrition, in hygiene, safety, with longer shelf life, reducing food losses and waste, and environment sustainable.