Dry Aging Meat Applications Overview

King Son Convertible IFP Aging Chiller Overview

King Son Convertible IFP Aging Chiller is a machinery, plant or laboratory equipment designed for the treatment of materials by a process involving a change of temperature such as cooling and refrigeration for refrigerated food process and beverage preservation.

King Son Convertible IFP Aging Chiller is also a machinery for the preparation of meat or poultry, is a food process and preservation equipment.

King Son Convertible IFP Aging Chiller is a Convertible Temperature Equipment that operates at a chilled, frozen, or variable temperature condition between approximately (+6°C/42.8°F to -12°C/10.4°F), which can display, processes and preserves merchandise and other perishable materials horizontally, semi-vertically, or vertically; with hinged transparent doors; that also has a user adjustable application temperature set point within the operating range of (+6°C/42.8°F to -12°C/10.4°F); and connected to a self-contained condensing unit.

King Son Convertible IFP Aging Chiller is a new refrigeration and food preservation solution for the modern AIoT-era. It is incorporated with A7 Intelligent Food-Tech Controller and designed with Constant Temperature and Humidity Multiple Points Monitoring and Servo Control Technology to perform Convertible Temperature Refrigeration System between precision refrigeration and precision freezing for 5 novel next generation refrigeration technologies.

King Son Convertible IFP Aging Chiller is also a machinery for the preparation of meat or poultry, is a food process and preservation equipment.

King Son Convertible IFP Aging Chiller is a Convertible Temperature Equipment that operates at a chilled, frozen, or variable temperature condition between approximately (+6°C/42.8°F to -12°C/10.4°F), which can display, processes and preserves merchandise and other perishable materials horizontally, semi-vertically, or vertically; with hinged transparent doors; that also has a user adjustable application temperature set point within the operating range of (+6°C/42.8°F to -12°C/10.4°F); and connected to a self-contained condensing unit.

King Son Convertible IFP Aging Chiller is a new refrigeration and food preservation solution for the modern AIoT-era. It is incorporated with A7 Intelligent Food-Tech Controller and designed with Constant Temperature and Humidity Multiple Points Monitoring and Servo Control Technology to perform Convertible Temperature Refrigeration System between precision refrigeration and precision freezing for 5 novel next generation refrigeration technologies.

- King Son Constancy Precision Refrigeration Technology (0°C/ 32.00°F - 6°C/ 42.80°F)

- King Son Constancy IFP Chilling Technology (0°C/32℉ – above Initial Freezing Point of food)

- King Son Constancy Superchilling Technology (- 1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point of food)

- King Son Constancy IFP Superchilling Thawing/Tempering Technology (- 2°C/28.40°F to -5°C/23.00°F)

- King Son Constancy Precision Freezing Technology (- 12°C/10.40°F)

that preserves and processes food in uniform conditions and environments, with temperature fluctuations 0.3°C/0.54°F and humidity fluctuations ±5%. King Son Convertible IFP Aging Chiller is an AIoT machine which incorporates King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform for remote distance servicing and collaboration – thus helping build new partnership opportunities through IoT eco-system.

King Son Convertible IFP Aging Chiller

King Son Convertible IFP Aging Chiller

- King Son Convertible IFP Aging Chiller is designed with King Son Constancy IFP Chilling Technology mainly, specifically designated applied for high value fruit, vegetable, fish, meat process and preservation between 0°C/32℉ and above Initial Freezing Point of food, without freezing.

- King Son Convertible IFP Aging Chiller dry ages food above its initial freezing point (IFP) thereby contributing to food’s tenderness and flavor, as well as preserving food either above IFP or in super-chilling temperature to extend shelf life to reduce food waste and help contribute to eco-friendly environments.

-

(Source

- Why dry aged beef?

- https://www.katherinefarm.com/blogs/around-the-farm/93774723-why-dry-aged-beef )

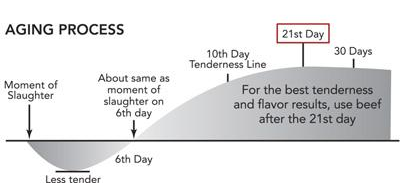

What is meat aging?

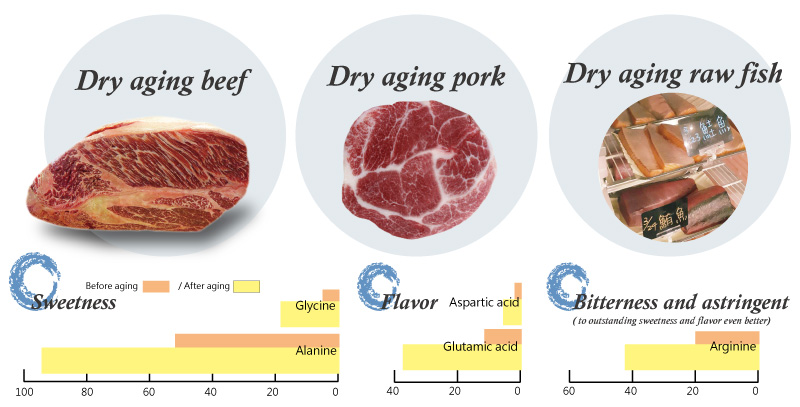

What is meat aging? After animal being slaughtered, the cells within the meat of the animal lose vitality, the enzyme reaction rate and the reaction object is no longer subject to cell control. The enzyme begins to catalyze the decomposition of meat: the macromolecule protein decomposition to small molecule amino acid, Liver glycogen to glucose, adenosine triphosphate (ATP) responsible for energy transport is broken down to a taste of monophosphate myosin (IMP), Lipid in the fat is broken down to fatty acids that produces meat and nut fruit flavor. Connective tissue and muscle fibers of various supporting proteins are also broken down to small molecules, the meat becomes more flavorful and more tender. The process of continuous decomposition of the enzyme is called "aging".

Another attractive feature of the dry-aging process is the release of unique natural aromatic flavours and fragrances of the ingredient. From previous studies, it has been observed that aromatic fragrances resembling nuts, dairy, mushroom, chocolate, truffle, popcorn and butter were released. When undergoing the dry-aging procedure for an extended period of time, the ingredient may even release aromas resembling blue cheese.

Dry aging enhances sweetness and aroma: enzymes break down proteins into flavored amino acids, transform glycogen into glucose, increase Mena reaction.

What and How Does King Son Convertible IFP Aging Chiller dry aging process and preservation? and why choose King Son the best dry aging solutions?

King Son Convertible IFP Aging Chiller provides ideal dry aging environment and condition

- King Son Convertible IFP Aging Chiller provides meat with an ideal dry aging uniformity environment, where meat ages and preserves in constant temperature and humidity above initial freezing point, temperature fluctuation ±0.3°C/0.54°F and humidity fluctuation ±5% and embraced in UVC air ventilation bacteriostatic environment that ensures food aging safety.

- The dry aging process is to place fresh chilled meat (without packaging), which has undergone pre-cooling treatment after slaughter, in the controlled temperature, humidity, and air velocity for longer time process. Commonly used dry aging temperature is -2 ℃/28.40°F to + + 4°C/39.20°F, related humidity between 50% RH and 90% RH. Wet aging uses vacuum packaging for aging.

- Taking dry aging beef rib eye as the example, it is recommended to place the fresh chilled beef rib eye (without packaging) in King Son IFP Meat Aging Chamber, set controlled temperature at -0.5 ℃/31.10°F above initial freezing point of beef rib eye and controlled humidity at 80% for 42 days dry aging process experiment.

Dry aging process naturally and safely in King Son Convertible IFP Aging Chiller:

- When dry aging process beef rib eye in King Son IFP Meat Aging Chamber, the beef rib eye undergoes two notable changes. Firstly, in the beef itself, the natural enzyme will break the muscle connective tissue which makes the meat becomes tenderer. Secondly, the water evaporates from the muscle tissue of the beef, this makes the flavor of the beef more concentrated. Furthermore, the beef’s natural enzymes and their external microbiological interactions improve the tenderness, flavor, juicy of the beef.

- The Process:

- Enzymatic action

- Endogenous proteolytic enzymes from the meat itself as well as from the specific beneficial moulds weaken the structural myofibrillar proteins in the meat. This takes 10 to 14 days and results in a more tender meat. At this stage the meat flavour can usually be described as buttery and smooth.

- Enzymatic action

- Evaporation

- Loss of water from the meat by evaporation causes concentration of the remaining proteins and increases flavour intensity to a nutty almost gamey taste. Final water loss can be up to 50 per cent and depends on the relative humidity used during drying.

King Son Convertible IFP Aging Chiller monitor and control dry aging controlled factors

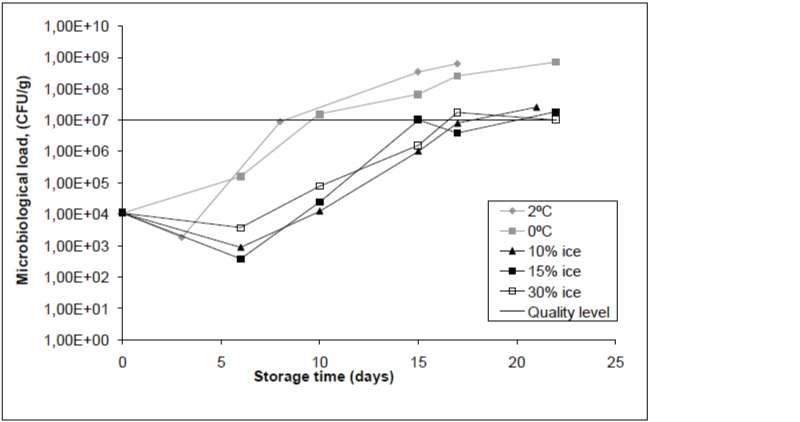

- Three main factors are taken into account when dry aging process – the controlled temperature, humidity and air velocity.

- Aging Temperature, with fluctuation ±0.3°C/0.54°F

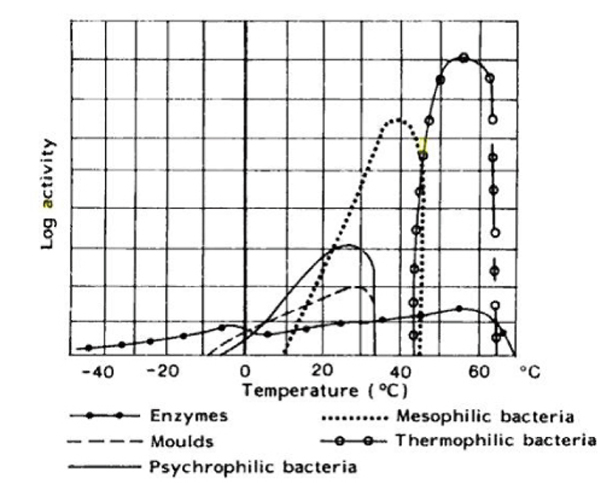

- Aging at a higher temperature can accelerate tenderness development, however, amplified microbial growth becomes a serious problem at higher temperatures.

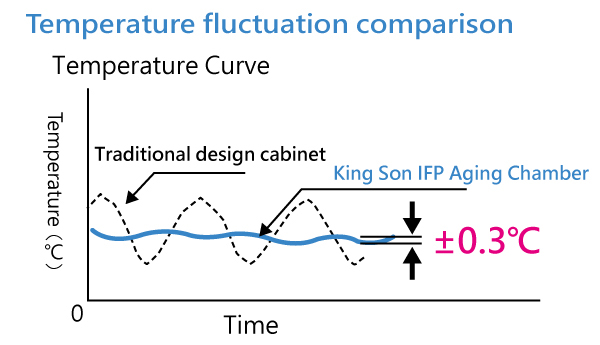

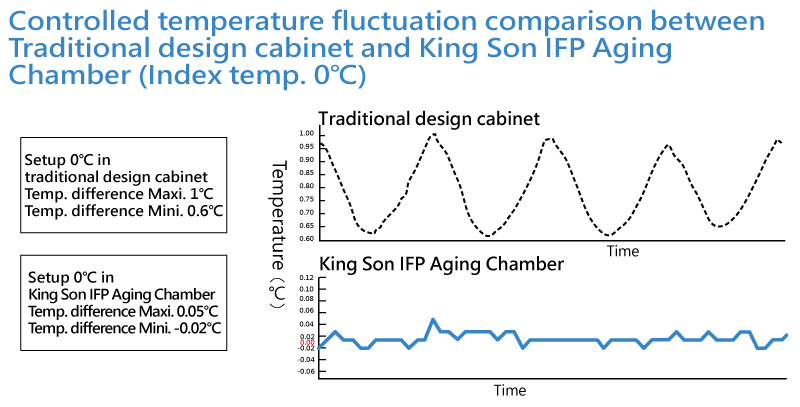

- Temperature fluctuation affects food quality and safety.

- Temperature fluctuation in traditional designed refrigerator and freezer that normally is about 3℃/5.40°F - 5℃/9.00°F.

- Temperature fluctuations influences the greatest reliability in food quality of taste, texture and flavor.

- It is well known that both enzymatic and microbiological activity are greatly influenced by temperature that temperature changes have greater impact on microbiological growth than on enzymatic activity for food safety.

- Therefore, to maintain high quality and product consistency, temperature swings of more than 1℃ above or below the desired temperature in the storage room must be avoided.

- Dry aging Meat by King Son Constancy IFP Chilling Technology

- To eliminate temperature fluctuation impacts on food quality and safety, King Son researched, developed and launched Constancy IFP Chilling Technology in 2015 that provides a unique constant temperature stability ±0.3°C/0.54°F, which reduces the traditional temperature fluctuation from ±5℃/23℉ down to ±0.3°C/0.54°F.

- King Son Convertible IFP Aging Chiller is designed to produce

- 0.01℃/0.018℉ controlled resolution in constant temperature above Initial Freezing Point, with controlled temperature fluctuation ±0.3°C/0.54°F

- 0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, with controlled humidity fluctuation ±5% RH.

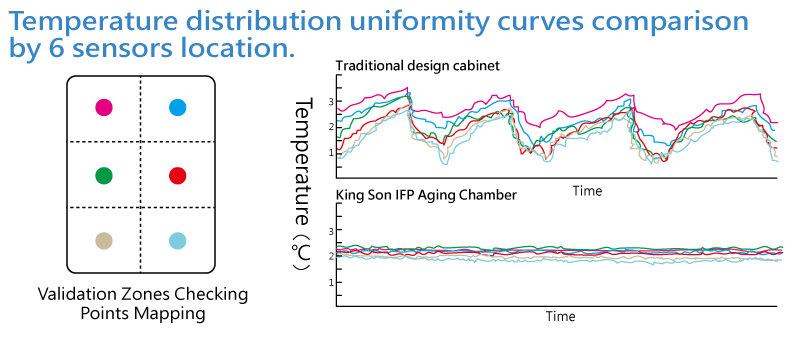

- Temperature and humidity fluctuation comparison

- King Son Convertible IFP Aging Chiller is incorporated with 360° Air Cooling System, it is a unique design of the wind field, thru that cooling air inputs into to the chamber that produces uniform temperature distribution, so that cooling is more stable, efficient and allows for accurate temperature distribution uniformity inside the chamber.

- Temperature distribution uniformity curves comparison by 6 sensors location

- Non uniformity temperature distribution in the traditional cabinet is the main reason produced food waste.

- King Son Convertible IFP Aging Chiller is designed to dry age meat in subzero, between 0°C/32 ℉ and above IFP (Initial freezing Point) of meat, in controlled constant temperature and humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% that prevents the temperature of the food’s cell membrane becoming lower than the temperature of Initial Freezing Point, without freezing and thereby enhancing more tenderness, flavor and juicy.

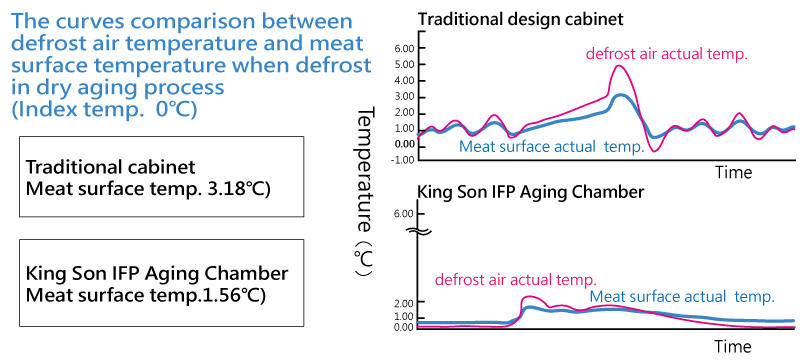

- The controlled temperature fluctuation comparison between Traditional design cabinet and King Son Convertible IFP Aging Chiller (Index temp. 0℃/32℉)

- King Son Smart Defrosting System

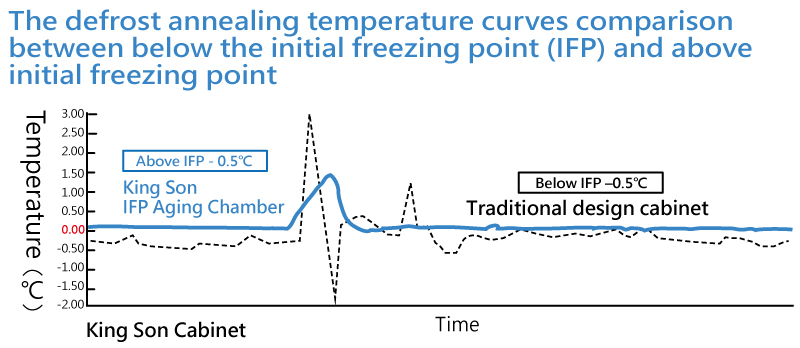

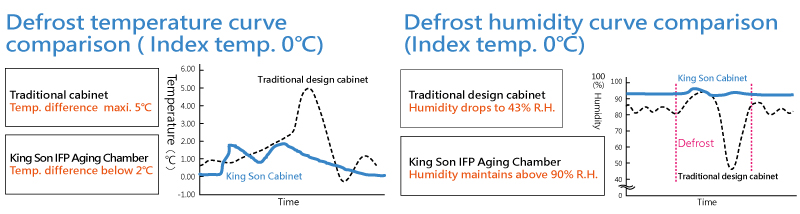

- In the traditional defrost mechanism, the temperature after finished defrosting is likely to occur too low that leads to food surface temperature lower than the initial freezing point of food, thereby causing unintended food freezing. King Son Smart Defrosting Technology overcomes this issue by ensuring food return temperature is not lower than IFP (initial freezing point).

- Frost accumulation results in decreased performance in heat exchangers and it is necessary to move out the accumulated frost. The traditional design defrosting system typically runs only in specific periods of time and the time when the heat exchanger is not in active operation. Such solutions will use too much energy when in small amount of ice loading and too little energy use when there is more ice.

- King Son unveiled Smart Defrosting System in 2015 with leading edge technology in the refrigeration industry to solve this issue.

- The defrost return temperature curves comparison between below the initial freezing point (IFP) and above initial freezing point

- The temperature curve comparison between defrost air and meat surface (Index temp. 0℃/32℉)

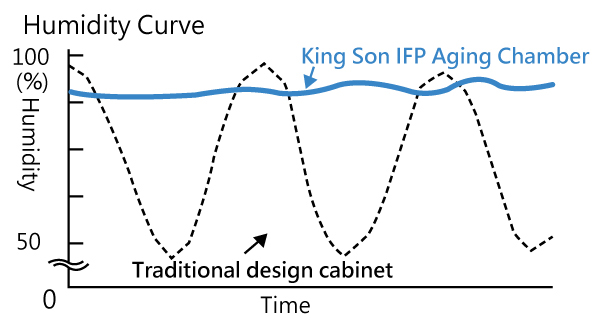

- Aging Related Humidity, with fluctuation ±5%

- The amount of humidity should be monitored closely, because too much will allow disproportionate microbial growth, whereas too little will cause excessive shrinkage.

- Efficient moisturizing

- During dry aging process, of the biggest concern is the excessive drying loss of the food, resulting in food’s weight loss and cost loss. King Son Convertible IFP Aging Chiller is designed with humidity function that humidifies meat, keeps meat surface moist which enhances texture and palatability of meat. Additionally, King Son Convertible IFP Aging Chiller also has an optional model with constant high humidity function available for high humidity process and preservation.

- King Son Convertible IFP Aging Chiller is designed to produce 0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, and controlled humidity fluctuation ±5% RH.

- Air velocity

- It is equally critical since it acts as a medium for moisture removal from the refrigerated area. Inadequate air velocity will permit undue moisture to condense on the product, and as a result, off-flavors and aromas, as well as spoilage, will occur. On the other hand, if the air velocity is too high, this will result in excessive surface drying, with resulting weight and trim losses.

- King Son Convertible IFP Aging Chiller is incorporated with 360° Air Cooling System, it is a unique design of the wind field, thru that cooling air inputs into to the chamber that produces uniform temperature distribution, so that cooling is more stable, efficient and allows for accurate temperature distribution uniformity inside the chamber.

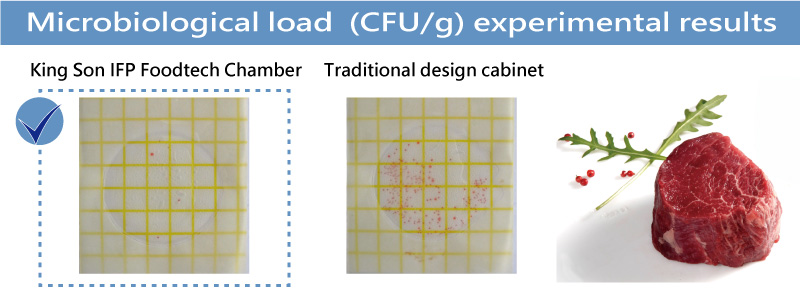

King Son Convertible IFP Aging Chiller provides UVC Air Ventilation Bacteriostatic System for antibacterial and microbiological control

- The use of ultraviolet (UV) light to eliminate bacterial cells is well known for fresh meat. A more sophisticated approach to manage the dry aging process is to install UV. Air is through the sealed UV channel to circulate in the aging zone of the chamber.

- King Son UVC Air Ventilation Bacteriostatic System remove the micro-organisms in the chamber enables a safe aging food process environment.

- Microbiological control

- Dry aging in natural condition and environment, without controlled temperature, humidity and air velocity that involves restricting bacterial growth and encouraging the growth of beneficial mould. During the dry aging process in nature environment, mould from the Thamnidium, Penicillium, Rhizopus and Mucor genera can be found on the surface of the meat. The most desirable is the Thamnidium mould as it has been shown to releases proteases that tenderize aging meat. Other mould species have been associated with infections in humans and production of harmful natural toxicants. They also do not provide any favorable characteristics for aging of meat.

- King Son Convertible IFP Aging Chiller is incorporated with UVC Air Ventilation Bacteriostatic System that ensures food safety during dry aging process. In the case study of dry aging experiments, we did not observe the growth of mold or other bacteria on the surface of pork loin and beef, because UVC Air Ventilation Bacteriostatic System performs bacteriostatic effectively that inhibits mould and microorganism growing.

- King Son Convertible IFP Aging Chiller preserves dry aged meat in Superchilling

- Once finished dry aging process, King Son Convertible IFP Aging Chiller can switch the process mode to superchilling preservation that preserves aged meat in superchilling (- 1.5°C/29.30°F to -2°C/28.40°F), with temperature fluctuation ±0.3°C/0.54°F and humidity fluctuation ±5% which extends the shelf life of meat for 2–3 weeks longer.

- The aim of superchilling is to preserve food products at temperatures just below their initial freezing point; low enough to substantially reduce bacterial activity but high enough to avoid significant levels of bigger size ice crystal growth as frozen does that can cause food structural damage. Traditional frozen meat can be extended for a long time. However, large amounts of water frozen out lead to serious texture microstructural change and drip loss after thawing.

To produce the best quality dry-aged meat, King Son IFP Meat Aging Chamber provides an ideal and safe aging environment where it automatically regulates the controlled temperature, humidity and air velocity thus creating the optimal conditions for the activation of the natural meat enzymes to break down protein and connective tissues of the meat to enhance to its tenderness, and allowing moisture to evaporate from the muscle to create a greater concentration of meat flavor and taste.