Beef aging

Case Study: Dry aging beef above Initial Freezing Point

In this study, we use weight change, pH value, shear force value, VBN value, glutamic acid content and flavor change as indicators to assess changes in the aging quality of the rib eye through the process of dry aging.

Dry aging conitions and parameters

- Temperature: -0.5℃, above initial freezing point -1.7℃

- Humidity: 80%RH

- Aging time: 35 days

The rib eye achieved a stable state in the required 35 days needed for dry aging

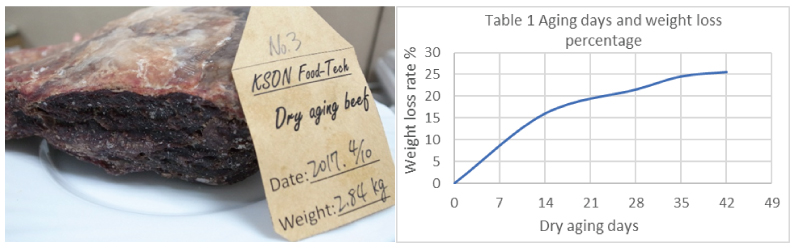

Appearance and weight change

-

Raw frozen rib eye

-

Dry aging process after 35 days

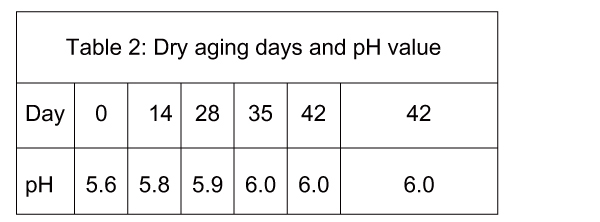

PH value change

-

PH value between 5.8-6.2 is defined as fresh meat, between 6.3-6.6 is defined to sub-fresh meat, and pH above 6.7 is spoiled meat.

- Throughout the entire 42 days IFP dry aging process, the quality of rib eye is within the fresh meat levels of pH, indicating that there is no significant deterioration of the quality of meat.

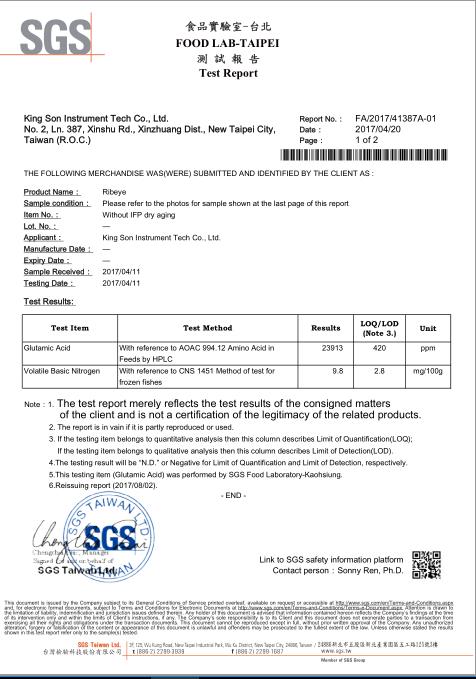

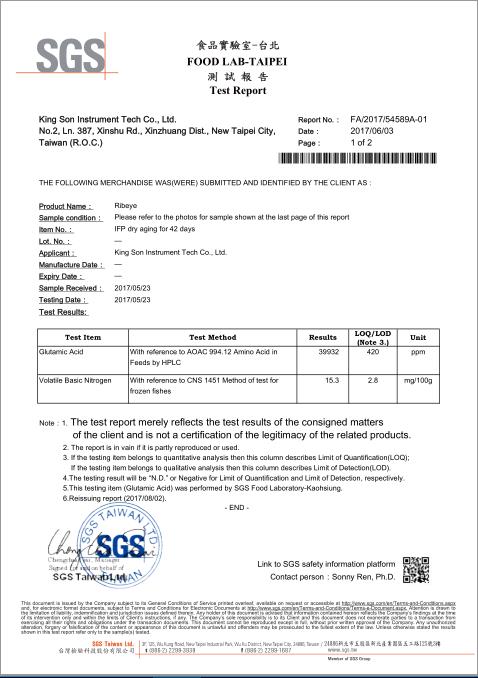

Measurement of Volatile basic ni-trogen

- Volatile basic nitrogen (VBN) is a general term referring to the presence of amines and ammonia within the food’s tissue and composition as produced by the activities of microorganisms and enzymes.

- In general, if the VBN value ≦ 15mg/100g is a fresh meat, VBN value between 15 to 25 mg/100g is belonged to sub-fresh meat, if the VBN value is greater than 25mg/100g is a spoiled meat.

- The VBN value was 9.88mg/100g on raw rib eyes and the VBN value on day 42 into the dry aging process to be 15.3 mg/100g which are all within the standards of fresh meat.

From the results of pH and VBN measurements, we can confirm that IFP dry aging process is safe for foods, which can be attributed to the stable IFP dry aging process environment provided by King Son IFP Aging Chamber.

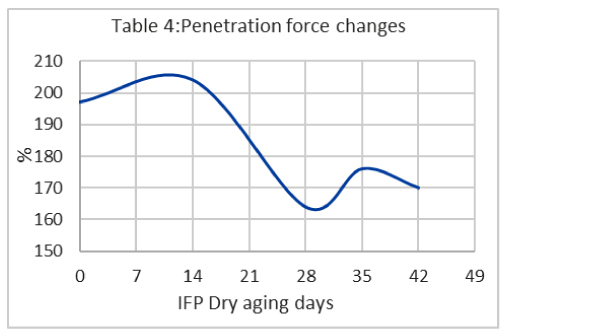

Penetration force measurement

- On the whole process, tenderness within the rib eye starts to be seen from day 14 onwards. Before this, the penetration force was around 200 g. After 28 days, the penetration force fell to 170 g, which in effect is around a 15% decline. This indicates that the rib eye has under-gone significant changes, and is a clear indicator that the quality of the rib eye has increased.

Glutamine acid and aroma devel-opment

- In the process of aging, the protein molecules in the meat will break down into smaller amino acid fragments, including amino acid species which are associated with perceived savoury and delicious-ness. One such amino acid is Glu-tamic acid, which is the amino acid associated with the savoury umami flavor, is present in the form of monosodium glutamate which in turn is the main compo-nent of sodium glutamate. Therefore,we selected glutamate as a monitoring indicator to observe the changes of glutamic acid contents during IFP dry aging process.

- We found that the glutamic acid content increase significantly during IFP dry aging process that varies by different sample taken locations. The glutamic acid con-tents increase between 16% and 67%, from 23913 ppm up to a maximum 39932 ppm, this result provides a scientific evidence that IFP dry aging process can increase the delicious taste and umami flavor of meat.

- One more distinguishing charac-teristic of the IFP dry aging process is that it can induce the develop-ment unique aromas within the food that is not otherwise present in the food before. In this experi-ment, after 14 days the rib eye began to develop special aromas familiar to milk and cheese. This result is expected from observa-tion made in past literature. Com-bining with our own observations, the aroma development at first was produced from the fat and slowly to the lean muscle parts of the meat, therefore, we can rea-sonably speculate that the aroma source is the aromatic fatty acid produced by the decomposition of fat after aging. Aside from the production of aromatic fragrances, the rib eye exhibited moistness, which can be

- clearly observed through the cut slide of the rib eye as seen from figure 6. It is worth noting that this additional moisture does contra-dict with the observation of dry aging induced weight loss. The weight loss is caused by overall water evaporation from the meat, while the additional moisture is derived from cells within the mus-cles of the meat as a result of the dry aging process. Despite this effect, under extended periods of dry aging, however, it is still ex-pected that the meat will still lose its moisture due to excessive water evaporation.

To summarise on the above experimental results, during IFP dry aging process, the weight loss of rib eye tends to be stabalises after day 35, the penetration force value tends to stabilize after about 28 days and begins to produce the additional moisture after the 35 days. The pH value and VBN values of rib eye on day 42 are both within the range of being a fresh meat after 42 days. In all, these results demonstrate that there is a viable potential business model around the dry aging of rib eye using the King Son IFP Aging Chamber. Rib eyes are matured and ready on day 35 for sale or cooking, and can be also preserved in the same chamber for further aging and extends shelf life for one more week, totaling 42 days. Fully dry aged beefs can also be stored in other mediums throughout the distribution chain. From exterior observations, pH value, VBN value and other metrics, the rib eye did not exhibit signs of spoilage. This is due to the technical designs of the King Son IFP Aging Chamber, which provides constant temper-ature and humidity and UVC Air Ventilation Bacteriostatic System,thus playing the most important role in ensuring the quality safety of the meat during IFP dry aging process.