Chamber unique features

King Son Convertible IFP Food-Tech Chamber product family series is designed with unique novel next generation refrigeration technology and industry innovation for food process, quality, safety and services.

King Son Convertible IFP Food-Tech Chamber product family series includes

-

King Son Convertible IFP Aging Chiller

-

King Son Convertible IFP Sub Chiller

-

King Son Convertible IFP Superchiller

-

King Son Convertible IFP Superchilling Thawer

-

King Son Convertible IFP Lab Chamber

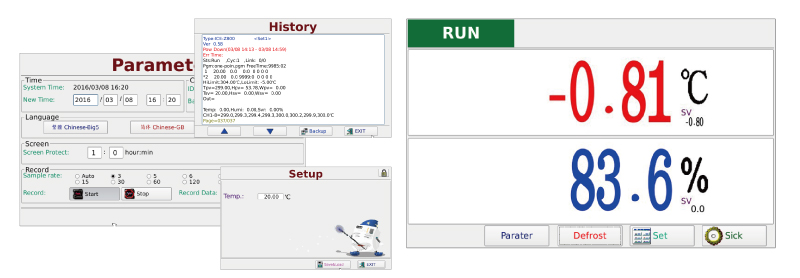

King Son A7 Intelligent Food-Tech Controller

-

King Son A7 Intelligent Food-Tech Controller is built on an embedded IPC (industry personal computer), which based on 64-bit ARM CPUs, firmware and operation with Linux kernel (multi-core) OS, particularly suitable for the development of proprietary applications and solutions for energy-saving, environmental monitoring and remote care.

-

King Son A7 Intelligent Food-Tech Controller with 6 "LCD color touch display is designed with Fuzzy temperature control technology and Intelligent PID (PWM) servo algorithm technology that effectively algorithm the energy required for Temperature rise and cooling, and incorporated with multi-track temperature detection (8CH Sensor) interface, in which multiple points temperature control ch1 - ch8 that performs temperature resolution ±0.01℃/0.018°F, relative humidity resolution ±0.1%.

-

King Son A7 Intelligent Food-Tech Controller is embedded with USB device, which records aging and chamber operational history in multi-track analysis curve charts that provides the records of food process flow, in line with FDA HACCP (Hazard Analysis and Critical Control Points) requirements.

King Son Intelligent Temperature Control 3D Dynamic Induction Technology

-

King Son Convertible IFP Food-Tech Chamber product family series is incorporated with King Son Intelligent Temperature Control 3D Dynamic Induction Technology that performs intelligent matrix management for how much food process and preservation volume, food placement location, what temperature, humidity and electrical energy consumption needed in the chamber, which increases aging process efficiency and best aging quality.

-

King Son Intelligent Temperature Control 3D Dynamic Induction Technology can automatically determine the process & preservation according to the size/quantity of the food, optimal placement location and calculate that as real time operation parameters dynamically to adjust energy consumption and fine-tune temperature distribution uniformity in the chamber for energy saving.

King Son Constant Temperature and humidity multiple points monitoring and servo control technology

King Son Convertible IFP Food-Tech Chamber is designed with Constant Temperature and humidity multiple points monitoring and servo control technology, in which

-

Channel 8 (ch8) is designed to monitor and record the ambient temperature of the chamber that ensures that the machine is running under safe conditions and environments.

-

Channel 7 (ch7) is designed to monitor and record the working temperature of the refrigeration compressor, which ensures the working quality and safe operational protection of the chamber.

-

Channel 6 (ch6), Channel 5 (ch5) are designed to monitor and record the food temperature at initial freezing point in aging process zone and servo domain zone; Channel 1 - Channel 4, ch1~ch4, are designed to monitor and record the temperature of UV device and sub servo control zone that ensures the aging food quality and safety.

King Son Convertible IFP Food-Tech Chamber product family series is designed to achieve the unique designated features performed by King Son Constancy IFP Chilling Technology and King Son IFP Superchilling Technology.

-

0.01℃/0.018°F controlled resolution in constant temperature above Initial Freezing Point, with controlled temperature fluctuation ±0.3℃/0.54°F.

-

0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, with controlled humidity fluctuation ±5% RH.

-

that prevents the temperature of the food's cell membrane becoming lower than the temperature of Initial Freezing Point, without freezing and thereby enhancing more tenderness, flavor and juicy.

King Son Convertible IFP Food-Tech Chamber product family series is incorporated with a variable frequency compressor, energy saving 25% - 30% and use R134a, R404 environmental friendly cooling refrigerant for refrigeration process.

King Son Convertible IFP Food-Tech Chamber product family series can preserve the aged meat in superchilling conditions, with 20% ice fraction on the outer layer of food, without completely freezing that can prolong shelf life longer to 2–3 weeks which significantly reduce food waste and energy saving.

King Son Convertible IFP Food-Tech Chamber product family series is incorporated with 360° Air Cooling System, it is a unique design of the wind field, thru that cooling air inputs into to the chamber that produces uniform temperature distribution, so that cooling is more stable, efficient and allows for accurate temperature distribution uniformity inside the chamber.

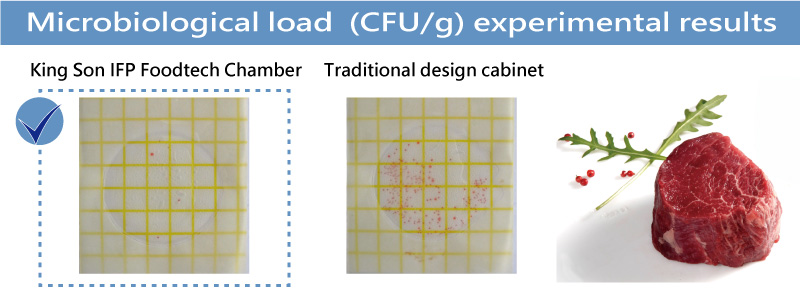

King Son Convertible IFP Food-Tech Chamber product family series is also incorporated with UVC Air Ventilation Bacteriostatic System for antibacterial and microbiological control.

King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform

King Son Convertible IFP Food-Tech Chamber product family series is incorporated with remote distance servicing and collaboration– thus helping build new partnership opportunities through AIoT eco-system.

- Provides customers field services.

-

Sustainable machinery - From reactive to proactive repairs and services.

-

Reduction in errors - The AIoT can guide field technicians to the source of the issues, as well as the best course of action.

-

Predictive maintenance - Field service agents will have the ability to see performance more clearly and accurately. Wear and tear, along with fracturing can be immediately reported without human involvement for predictive maintenance.

-

100 percent uptime - The AIoT will change the speed of repairs and real-time monitoring. Heating and cooling units can self-report any maintenance issues. Soon, field service technicians can optimize machines via remote control – from anywhere in the world.