Cod fillets 28 days Super-chilling preservation

Case study: Cod fillets 28 days Superchilling preservation

Abstract

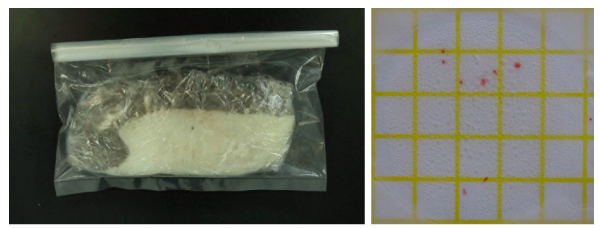

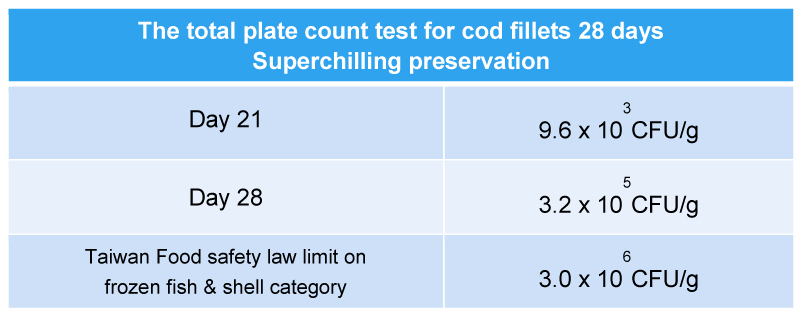

In this study, the cod fillets were used to do a 28 days Superchilling preservation test in King Son Convertible IFP Superchiller. Cod sampling inspection were done on day 21 and 28 to check the total plate count (aerobic plate count). It was found that the total plate count on cod fillet by Superchilling preservation in King Son Convertible IFP Superchiller on day 28 are 3.2X105 CFU/g, which are lower than the limit of 3X106 CFU/g, prescribed by Taiwan Ministry of Health and Welfare. This result shows the excellent Superchilling preservation performance and value performed by King Son Convertible IFP Superchiller.

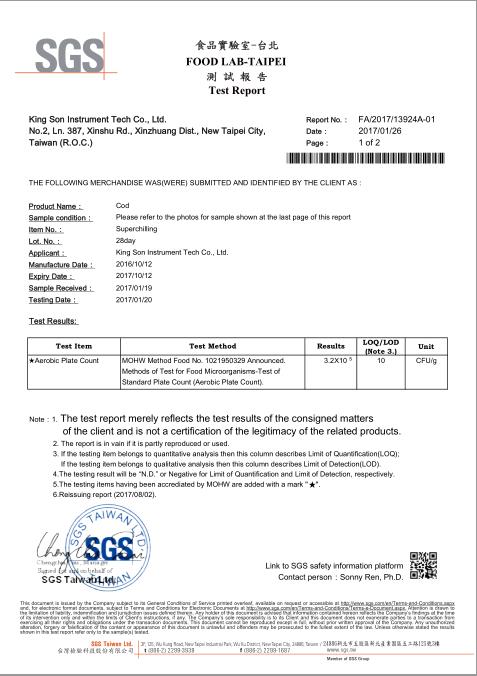

Test Material and Equipment

The samples used in this test are vacuum-packaged frozen cod fillet, purchased from Carrefour supermarket, and the test equipment used in this Superchilling preservation experiment is King Son Convertible IFP Superchiller, manufactured by King Son Instrument Tech., Co. Ltd.

Test procedures and method

- Setup Superchilling preservation temperature at -2.2℃/28.04℉ in King Son Convertible IFP Superchiller.

- Purchased frozen cod fillets from Carrefour supermarket and placed them immediately in King Son Convertible IFP Superchiller for 28 days Superchilling preservation test.

- Removed one piece of cod fillets as the sample on day 21 and 28 respectively, packed it by plastic wrap and put it into cleaning sealed plastic bag and then immediately delivered to SGS Taiwan food lab for the total plate count (aerobic plate count) inspection.

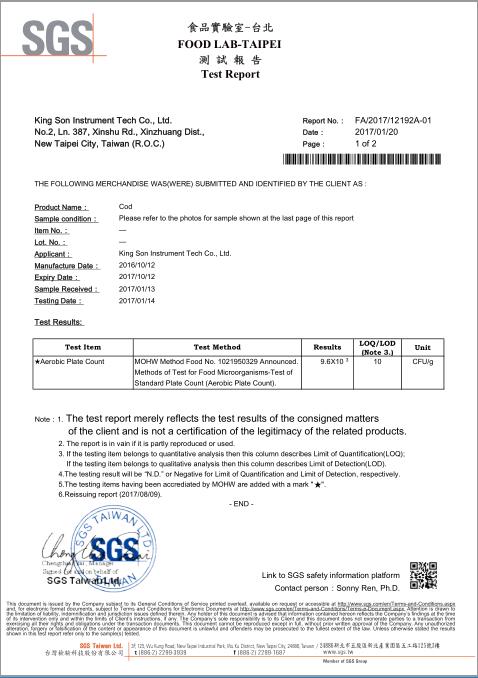

The total plate count test

Learned from above SGS Taiwan food lab test results, the cod fillets were subjected to a 28-day Superchilling preservation test, after SGS tested, the total plate count (aerobic plate count) on cod fillet samples on day 21 or day 28 were lower than Taiwan food safety law prescribed limits 3.0X105 CFU/g, in which the total plate count on day 21 is even much lower than raw food edible limits 105 CFU/g.

Conclusions and discussions

Superchilling preservation is a novel next generation food preservation technology. The advantages performed by Superchilling technology and process are

- preserves food very well, without damage food tissue;

- energy saving, since Superchilling is partial freezing on the surface of food;

- shorter thawing time needed for food process;

- bacterial growth inhibition

Besides the traditional refrigeration and freezing, Superchilling technology provides an alternative for food process and preservation.

Learned from above experimental results, King Son Convertible IFP Superchiller can preserve cod fillets in Superchilling environment for 28 days that the total plate count (aerobic plate count) on cod fillets are below Taiwan Food safety law limits. King Son Convertible IFP Superchiller is incorporated with Foodtech Controller and designed in Constant Temperature and humidity multiple points monitor, and servo control technology commercializes and realizes Superchilling process and preservation mass production in price performance value.

The total plate count test for Cod fillets Superchilling preservation on day 21

The total plate count test for Cod fillets Superchilling preservation on day 28