King Son Convertible IFP Sub Chiller Overview

King Son Convertible IFP Sub Chiller Overview

King Son Convertible IFP Sub Chiller is also a machinery for the preparation of meat or poultry, is a food process and preservation equipment.

King Son Convertible IFP Sub Chiller is a Convertible Temperature Equipment that operates at a chilled, frozen, or variable temperature condition between approximately (6°C/42.8℉ to -12°C/10.4℉), which can display, processes and preserves merchandise and other perishable materials horizontally, semi-vertically, or vertically; with hinged transparent doors; that also has a user adjustable application temperature set point within the operating range of (6°C/42.8℉ to -12°C/10.4℉); and connected to a self-contained condensing unit.

King Son Convertible IFP Sub Chiller is a new refrigeration and food preservation solution for the modern AIoT-era. It is incorporated with A7 Intelligent Food-Tech Controller and designed with Constant Temperature and Humidity Multiple Points Monitoring and Servo Control Technology to perform Convertible Temperature Refrigeration System between precision refrigeration and precision freezing for 5 novel next generation refrigeration technologies.

-

King Son Constancy Precision Refrigeration Technology (0°C/32.00℉ to 6°C/42.80℉)

-

King Son Constancy IFP Chilling Technology (0°C/32.00℉ – above Initial Freezing Point of food)

-

King Son Constancy Superchilling Technology (-1.5°C/29.30°F to -2°C/28.40°F, just below Initial Freezing Point of food)

-

King Son Constancy IFP Superchilling Thawing/Tempering Technology (-2°C/28.40℉ to -5°C/23.00℉)

-

King Son Constancy Precision Freezing Technology (-12°C/10.40℉)

-

that preserves and processes food in uniform conditions and environments, with temperature fluctuations ±0.3°C/0.54℉ and humidity fluctuations ±5%. King Son Convertible IFP Sub Chiller is an AIoT machine which incorporates King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform for remote distance servicing and collaboration – thus helping build new partnership opportunities through IoT eco-system.

-

King Son Convertible IFP Sub Chiller is designed with King Son Constancy Precision Refrigeration Technology and King Son Constancy IFP Chilling Technology mainly, specifically designated applied for high value fruit, vegetable, fish, meat process and preservation in (0°C/32.00℉ to 6°C/42.80℉) and (0°C/32.00℉ – above Initial Freezing Point of food)

-

King Son Constancy Precision Refrigeration Technology (0°C/32.00℉ to 6°C/42.80℉)

-

King Son Constancy IFP Chilling Technology (0°C/32.00℉ – above Initial Freezing Point of food)

-

-

They are designed by King Son Constant Temperature and humidity multiple points monitoring and servo control technology to produce, achieve and perform Precision Refrigeration (0°C/32.00℉ to 6°C/42.80℉) and IFP Chilling (0°C – above Initial Freezing Point of food) conditions, met the requirements for Precision Refrigeration and IFP Chilling process and preservation.

-

0.01°C/0.018℉ controlled resolution in constant temperature above Initial Freezing Point, with controlled temperature fluctuation ±0.3°C/0.54℉.

-

0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, with controlled humidity fluctuation ±5% RH.

-

To prevent freeze denaturation of food, IFP Chilling temperature does not fall below the point where freezing is discernible (i.e. -2°C/28.40℉)

-

EC Marketing Regulation 1234/2007, Fresh poultry is defined as that which has been kept at temperatures between -2°C/28.40℉ and +4°C/39.20℉

-

USA poultry meat kept above -3.3°C/26.06℉ can be marketed as ‘fresh’ (US Poultry products inspection regulations 9CFR381)

-

-

-

-

King Son Constancy Precision Refrigeration Technology is a novel generation Food-Tech after traditional refrigeration and freezing for food process and preservation between 0°C/32.00℉ and 6°C/42.8℉ in controlled constant temperature and humidity conditions, with temperature fluctuation ± 0.3°C and humidity fluctuation ±5%.

-

King Son Constancy Precision Refrigeration Technology is applicable and available to meet when planning conditions for long term preservation a temperature difference of no more than 1°C in the circulating air should be aimed at, together with a short-term fluctuation of less than 0.5°C/32.90℉.

-

The consequence of fluctuations in temperature often cause condensation or moisture on preservation products, which is undesirable because it may favor the growth of microorganisms, in the case of fruits and vegetables, the growth of mold and the development of decay.

-

King Son Constancy Precision Refrigeration Technology application process

-

Fresh hold, freshness contained

-

Preservation

-

-

Preserved Korean sesame leaves freshness in King Son Convertible IFP Sub Chiller at 5.5℃/41.90℉ ℃, 94% R.H. for 2 months

-

It’s not easily to preserve sesame leaves freshness, since sesame leaves are very sensitive to temperature fluctuation. The best taste time of sesame leaves normally is only 4 days when keep it in traditional refrigerator. It’s very difficult to preserve volume sesame leaves well and freshness, especially when in harvest season.

-

after several times experiment test in King Son lab, King Son comes out proposal for Korean sesame growers to preserve sesame leaves at 5.5℃/41.90℉, 94% R.H. in which constant temperature fluctuation ±0.3°C/0.54℉, humidity fluctuation ±5% would be the most optimum preservation conditions to keep it well and freshness that extends the best taste time from 4 days to 2 months.

- The graphic chart of temperature and humidity curves demonstrated that King Son Convertible IFP Sub Chiller commercializes King Son Constancy Precision Refrigeration Technology (0°C/32.00℉ to 6°C/42.80℉), with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% to preserves Korean sesame leaves freshness for 2 months that is the core competence Food-Tech innovations that King Son developed for food industry with mass production economic value.

- King Son Constancy Precision Refrigeration Technology (0°C/32.00℉ to 6°C/42.80℉) is designed by King Son Constant Temperature and humidity multiple points monitoring and servo control technology to produce

-

0.01°C/0.018℉ controlled resolution in constant temperature above Initial Freezing Point, with controlled temperature fluctuation ±0.3°C/0.54℉

-

0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, with controlled humidity fluctuation ±5% RH.

-

-

-

Optimum Preservation Conditions for high value crops

-

The recommended conditions for commercial preservation of asparagus are 0°C/32.00℉ to 2°C/35.6℉ with 95 to 99% RH, yielding 14 to 21 days of preservation life. Maintaining a low storage temperature is critical to delay senescence, tissue toughening, and flavor loss. High RH is essential to prevent desiccation and to maintain freshness.

-

Truffles can be kept in good condition for 20 to 30 days at 0ºC/32°F with 90 to 95% RH. Preservation life is slightly reduced at 5°C/41°F. Attention must be paid to fluctuation of the refrigeration temperature around 0°C/32°F that could freeze truffles and completely destroy their texture.

-

Ginseng should be preserved at 0°C/32.00℉ with 95% RH or higher. Roots retain good quality for 2 months at 0°C/32.00℉.

-

-

The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks

-

The Initial Freezing Point (IFP) is the temperature in at any fixed pressure at which the liquid and solid phases of a substance of specified composition is in equilibrium. The freezing point of water is 0°C/32.00℉.

-

Foods and beverages do not freeze completely at a single temperature, but rather over a range of temperatures between 0°C/32.00℉ and Initial Freezing Point (IFP). In fact, foods are high in sugar content or packed in high syrup concentrations may never be completely frozen, even at typical frozen food storage temperatures. Thus, there is not a distinct freezing point for foods and beverages, but an initial freezing point at which crystallization begins.

-

The initial freezing point of a food or beverage is important not only for determining the food’s proper storage conditions, but also for calculating thermos physical properties. During storage of fresh fruits and vegetables, for example, the commodity temperature must be kept above its initial freezing point to avoid freezing damage. In addition, because there are drastic changes in the thermos physical properties of foods as they freeze, a food’s initial freezing point must be known to model its thermos physical properties accurately.

-

The initial freezing points of most foods are between -0.5°C/31.10℉ to -2.8°C/26.96℉.

-

IFP Chilling is the temperature range, defined between 0°C/32.00℉ and above Initial Freezing Point (IFP) of food.

-

IFP Chilling temperature can be used to process and preserve fresh fruits, vegetables, meat and fish at a little below 0°C/32.00℉ - but above the initial freezing point of food – without freezing, gives food maximum shelf life.

-

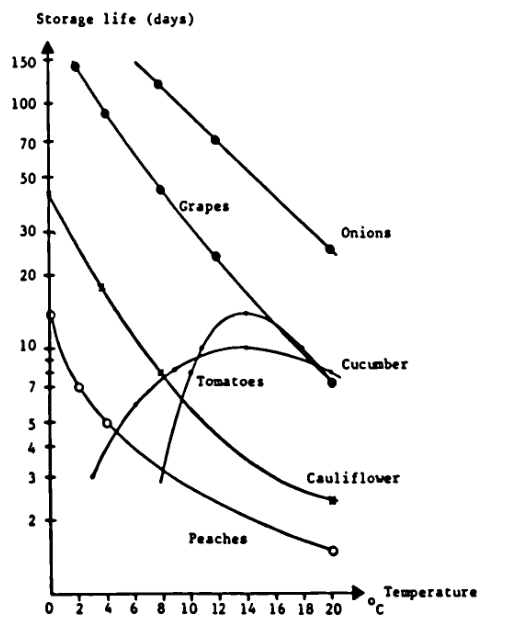

Figure 3. TTT-curves for some fruits and vegetables.

-

(Source: P. ZEUTHEN et al./ROCESSING AND QUALITY OF FOODS, VOLUME 3, CHILLED FOODS: THE REVOLUTION IN FRESHNESS, page 59

-

IFP Chilling application

-

Fresh hold. freshness contained

-

Preservation

-

Aging

-

Fermentation

-

Rigor off

-

Dehydration

-

Inspissation

-

-

Fresh foods demand novel refrigeration methods to preserve food products at controlled low temperature through complete cold chain from production, transportation and storage. Storage temperature is important in all stages of the products shelf life, and storage by producer, the retailer and the consumer. The market opinion survey results are fresh foods are better than frozen foods. Therefore, the demand for keeping the food fresh is increasing, and the requirement for keeping the right temperatures are essential. It is therefore important to develop and promote what and how Precision Refrigeration and IFP Chilled products above initial freezing point, without freezing, do have the much better fresh quality characteristics than refrigeration products.

-

Precision Refrigeration and IFP Chilling have great potential to enable safe, high quality and long term storage of foods without the consumer perceived detrimental effects of freezing. Energy and environmental benefits are envisaged due to reduced heat loads and higher storage temperatures (when compared to frozen food).

-

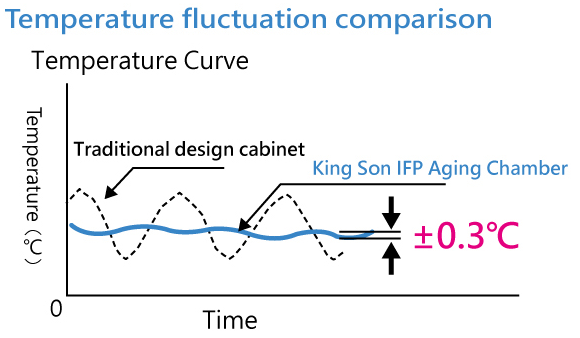

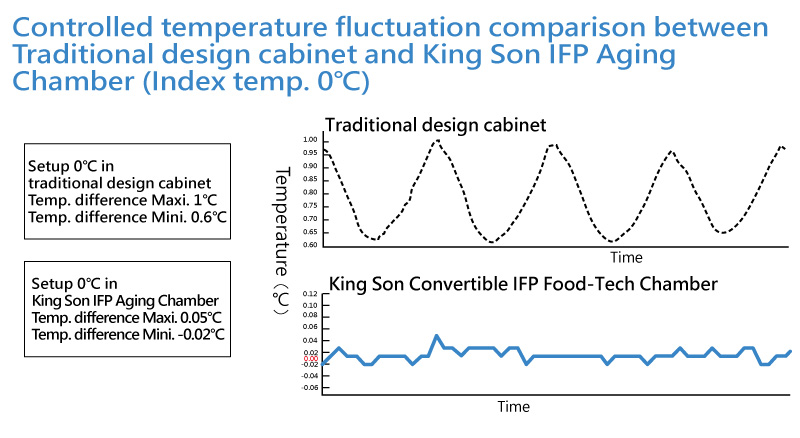

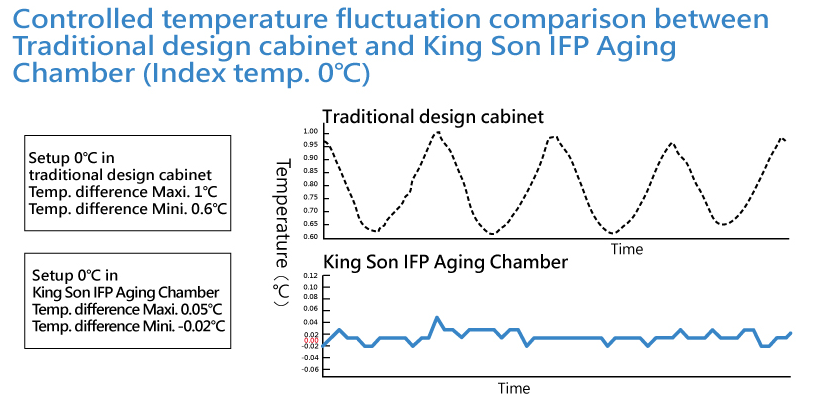

Most current designs in traditional refrigerator and freezer also rely on vapor-compression systems that are turned on or off at high and low set points, resulting in temperature fluctuations that exceed the recommended variation of ±5°C/9℉.

-

Non uniformity temperature distribution in the traditional cabinet is the main reason produced food waste.

In the fast-moving food industry of today, keeping up with the competition is of vital importance. Customers demand better and “newer” products almost every other day, and they also expect affordable prices and high availability. Being able to meet these demands means inventing new food products and using the best technology for processing them and keeping them fresh, tasty and healthy. With decades of product liability testing instrument experiences and as a Food-Tech equipment manufacturer, King Son is able to provide a wide variety of high-quality, state-of-the-art King Son Convertible IFP Food-Tech Chamber for food industry.

King Son Constancy IFP Chilling Technology (0°C/32.00℉ – above Initial Freezing Point of food)

-

The temperature ranges between 0°C/32.00℉ and Initial Freezing Point (IFP) of food that can be utilized for food preservation that can inhibit harmful microbes and pathogenic bacteria of proliferation, to improve taste and flavor enzymes, yeast and lactic acid bacteria activities, avoid residual hazards caused by the use of the fungicide or disinfectant to ensure food's original taste, quality, safety and value.

-

King Son Convertible IFP Sub Chiller is a novel generation Food-Tech equipment after traditional refrigerator and freezer, which is designed with King Son Constancy IFP Chilling Technology to process and preserve food in the temperature between 0°C/32.00℉ and above Initial Freezing Point (IFP) of food, in controlled constant temperature and 95% humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5 %.

-

King Son Constancy IFP Chilling Technology is designed to produce

-

0.01°C/0.018℉ controlled resolution in constant temperature above Initial Freezing Point, with controlled temperature fluctuation ±0.3°C/0.54℉

-

0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, with controlled humidity fluctuation ±5% RH.

-

-

The effects of King Son Constancy IFP Chilling Technology applied on the fresh food preservation mainly includes

-

King Son Constancy IFP Chilling can inhibit respiration, delay the respiratory peak and reduce the loss of nutrients. The exhaled volume of CO2 in the King Son Constancy IFP Chilling is less than that stored in normal temperature.

-

King Son Constancy IFP Chilling won’t destroy the cells, but improve the quality of fruits and vegetables in the vicinity of freezing temperature. In order to prevent from forming ice, fruits will secrete large amounts of antifreeze (its main ingredients are glucose, amino acids, aspartic acid etc.) to reduce the freezing point, or decompose the starch into sugar. These physiological changes improve the quality of fruits and vegetables in different degrees.

-

King Son Constancy IFP Chilling can inhibit the growth of microbial efficiently. Under the condition of King Son Constancy IFP Chilling, water molecules in fruits or vegetables are arranged in an orderly state, which reduce the content of free water available for the microbial. In the short and mid period preservation, King Son Constancy IFP Chilling can inhibit multiplication of microorganisms, better than the frozen temperature.

-

Since King Son Constancy IFP Chilling can inhibit chemical reaction strongly, the food quality in King Son Constancy IFP Chilling is better than that of the normal cold storage. King Son Constancy IFP Chilling also can inhibit lipid oxidation, non-enzymatic and other chemical reaction. The key for King Son Constancy IFP Chilling preservation is to realize a hibernation state of the product. The “hibernation” process is a cooling process during which the product can reduce its activity ability and energy consumption through the self-adaption, starting from the change of components within cells, and at the same time ensuring their own living life characteristics. It is a typical phenomenon of natural adaption.

-

-

King Son Convertible IFP Sub Chiller commercializes and performs the economic value of IFP Chilling at the temperature, between 0°C/32.00℉ and above Initial Freezing Point (IFP) of food, for food process and preservation in food industry.

-

The initial freezing points of most foods are between -0.5°C/31.1℉ and -2.8°C/26.96℉

-

King Son Convertible IFP Sub Chiller application

-

Fresh hold, freshness contained

-

Preservation

-

Aging/maturation

-

-

CHAPTER 8 Fahrenheit THERMAL PROPERTIES OF FOODS,Table 3 Unfrozen Composition Data, Initial Freezing Point, and Specific Heats of Foods.

-

CHAPTER 9 Celsius THERMAL PROPERTIES OF FOODS,Table 3 Unfrozen Composition Data, Initial Freezing Point, and Specific Heats of Foods.

By what and How King Son Convertible IFP Sub Chiller does Precision Refrigeration, IFP Chilling process and preservation?

-

In IFP Chilling process stage, food is chilled by pre-cooling function in King Son Convertible IFP Sub Chiller to above initial freezing point of food, without freezing, for IFP Chilling storage and preservation.

-

Why choose King Son for the best Precision Refrigeration, IFP Chilling storage and preservation solutions?

-

King Son Convertible IFP Sub Chiller provides food ideal Precision Refrigeration, IFP Chilling process condition and preservation environment.

-

Precision Refrigeration and IFP Chilling process and preserve food naturally and safely in King Son Convertible IFP Sub Chiller.

-

King Son Convertible IFP Sub Chiller monitors and controls Precision Refrigeration and IFP Chilling process and preservation factors.

-

King Son Convertible IFP Sub Chiller provides UVC Air Ventilation Bacteriostatic System for antibacterial and microbiological control.

-

King Son Convertible IFP Sub Chiller is available to preserves food in Superchilling.

-

-

King Son Convertible IFP Sub Chiller provides food with an ideal uniformity conditions and environment, where processes and preserves food in controlled constant temperature (0°C/32.00℉ to 6°C/42.80℉) and (0°C/32.00℉ – above Initial Freezing Point of food) and 95% high humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% and that embraced in UVC air ventilation bacteriostatic environment which ensures food storage and preservation safety.

-

Precision Refrigeration and IFP Chilling are new methods to preserve food fresh for 2-3 weeks, without the use of chemical additives, examples include salt in water, alcohol in water, or the mixing of two solids such as impurities in a finely powdered drug.

-

Temperature, with fluctuation ±0.3°C/0.54℉

-

Temperature fluctuation affects food quality and safety.

-

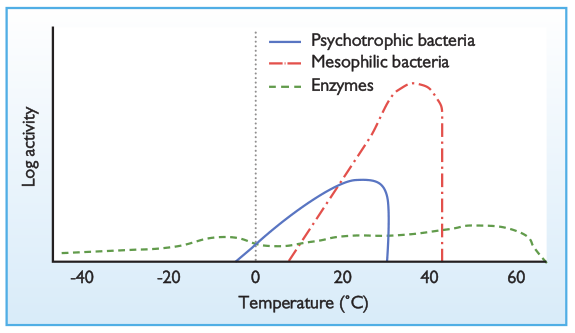

It is well known that both enzymatic and microbiological activity are greatly influenced by temperature that temperature changes have greater impact on microbiological growth than on enzymatic activity for food safety.

-

-

Relative enzyme activity and microbial growth rate in relation to temperature (Andersen et al., 1965)

-

(Source:

-

The evolving story of fish shelf-life management, International Meat Topics — Volume 1 Number 1, Page 1,

-

To eliminate temperature fluctuation impacts on food quality and safety, King Son researched, developed and launched King Son Constancy Precision Refrigeration Technology (0°C/32.00℉ to 6°C/42.80℉) and King Son Constancy IFP Chilling Technology (0°C/32.00℉ – above Initial Freezing Point of food) in 2015 that provides a unique constant temperature stability ±0.3°C/0.54℉, which reduces the traditional temperature fluctuation from ±5°C/9℉ down to ±0.3°C/0.54℉.

-

King Son Constancy Precision Refrigeration Technology and King Son Constancy IFP Chilling Technology are designed to produce

-

0.01°C/0.018℉ controlled resolution in constant temperature above Initial Freezing Point, with controlled temperature fluctuation ±0.3°C/0.54℉

-

0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, with controlled humidity fluctuation ±5% RH.

-

-

In addition, it should also be noted that reducing temperature variations to a minimum extent during Precision Refrigeration and IFP Chilling storage is of great importance.

-

King Son Convertible IFP Sub Chiller is a flexible and effective Precision Refrigeration and IFP Chilling storage and preservation equipment that meet the demands and fulfill the requests of more research on how to control and keep the required storage temperature above initial freezing point of food. The IFP Chilling preservation temperature should be stable enough to avoid freezing caused and to keep the degree of IFP Chilling within a narrow margin, between 0°C/32.00℉ and above Initial Freezing Point of food.

-

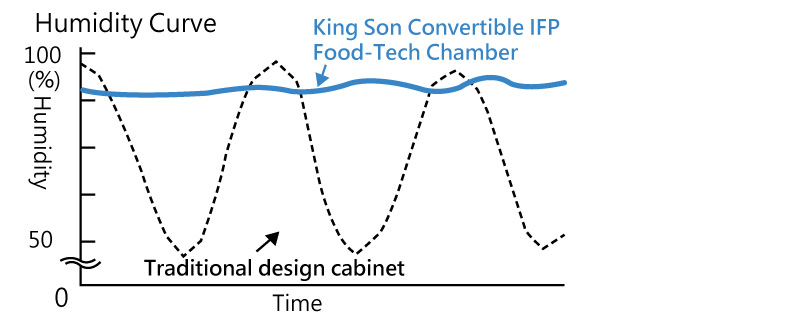

95% Related Humidity, with fluctuation ±5%

-

The amount of humidity should be monitored closely, because too much will allow disproportionate microbial growth, whereas too little will cause excessive shrinkage.

-

The humidity of the preservation conditions should be over 90 percent and the air velocity should be low to minimize food dehydration and weight loss.

-

King Son Convertible IFP Sub Chiller is designed to produce 95% related humidity, with 0.1% RH controlled resolution in constant temperature & humidity above Initial Freezing Point, and controlled humidity fluctuation ±5% RH.

-

-

Air velocity

-

It is equally critical since it acts as a medium for moisture removal from the IFP Chilling process area. Inadequate air velocity will permit undue moisture to condense on the product, and as a result, off-flavors and aromas, as well as spoilage, will occur. On the other hand, if the air velocity is too high, this will result in excessive surface drying, with resulting weight and trim losses.

-

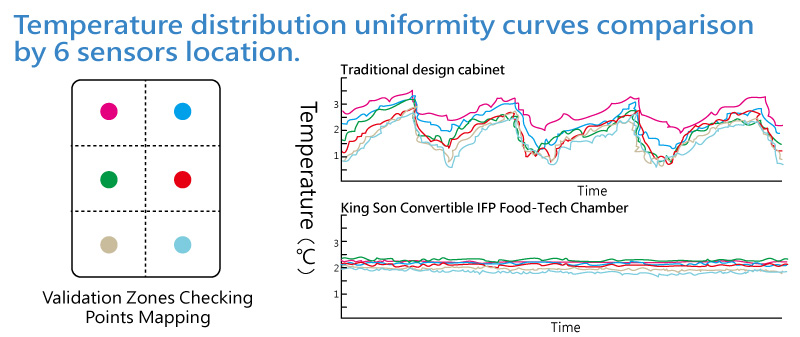

King Son Convertible IFP Sub Chiller is incorporated with 360° Air Cooling System, it is a unique design of the wind field, thru that cooling air inputs into to the chamber that produces uniform temperature distribution, so that cooling is more stable, efficient and allows for accurate temperature distribution uniformity inside the chamber.

-

Temperature distribution uniformity curves comparison by 6 sensors location

-

King Son Convertible IFP Sub Chiller provides UVC Air Ventilation Bacteriostatic System for antibacterial and microbiological control

-

The use of ultraviolet (UV) light to eliminate bacterial cells is well known for fresh meat. A more sophisticated approach to manage the IFP Chilling process and preservation is to install UV. Air is through the sealed UV channel to circulate in the IFP Chilling zone of the chamber.

-

King Son UVC Air Ventilation Bacteriostatic System remove the micro-organisms in the chamber enables a safe IFP Chilling food process and preservation environment.

King Son Convertible IFP Sub Chiller preserves food in Superchilling temperature

-

Once finished IFP Chilling process, King Son Convertible IFP Sub Chiller can switch the process mode to superchilling preservation that preserves food in superchilling (-1.5°C/29.30°F to -2°C/28.40°F), with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% which extends the shelf life of food for 3 – 4 weeks.

-

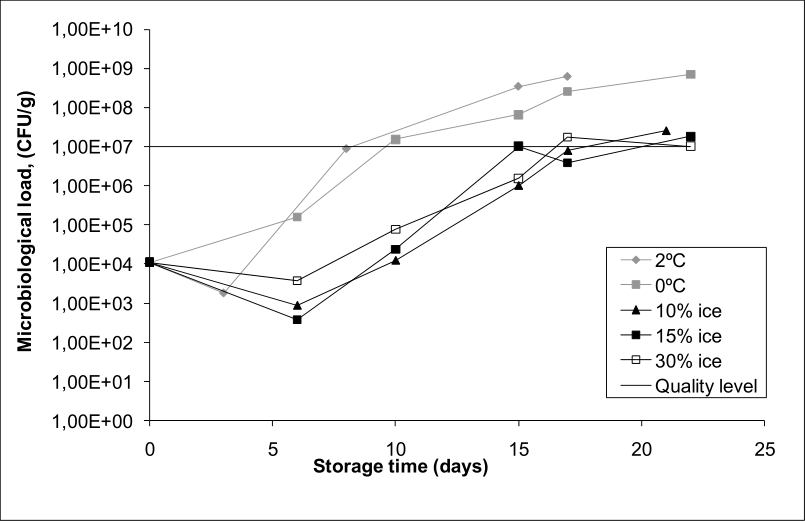

The aim of superchilling is to preserve food products at temperatures just below their initial freezing point; low enough to substantially reduce bacterial activity but high enough to avoid significant levels of bigger size ice crystal growth as frozen does that can cause food structural damage.

-

The quality limit of 107 CFU/g represents a usual microbiological quality measure, above which food is regarded as unfit for human consumption.

-

Figure 4 Microbiological load (total count) for unpacked chilled and superchilled salmon fillets

-

(Source:

-

Stevik, A.M. 2007. Microbiological level of unpacked, chilled and superchilled salmon fillets. In SINTEF Energy Research, Trondheim

King Son Convertible IFP Sub Chiller is designed for mechanical freezing process to treat food by IFP Chilling process at standard speeds.

-

Small batch IFP Chilling by mechanical freezing method to process and preserve thin or flat products, including high-value individually quick-frozen (IQF) products.

-

Small batch IFP Chilling to stabilize soft food and confectionery by mechanical freezing method before further processing.

-

Improve throughput, yield and hygiene for delicious product in slicing process operation.

-

Small batch IFP Chilling raw meats by mechanical freezing method for safer chilled storage, preservation and distribution.

-

Food types available application

-

Meat

-

Poultry

-

Sea food

-

-

-

Benefiting high-volume sub-chilling system manufactures requiring rapid chilling process fish, that the core temperature of fish chilled to above initial freezing point of fish, without freezing. King Son Convertible IFP Sub Chiller serves as a IFP chilling storage and preservation solution for sub-chilled foods in retailers operating in the final stages of sub-chilling value chain.

-

King Son Convertible IFP Sub Chillers well-suited for food retailer and food processing factory who needs to store fast mass production sub-chilled fish products. (that normally sub-chilling process by sub-chilling system).

-

King Son Convertible IFP Sub Chiller provides food with an ideal uniformity conditions and environment, where processes and preserves food in controlled constant temperature between 0°C/32.00℉ and above Initial Freezing Point (IFP) of food and 95% high humidity conditions, with temperature fluctuation ±0.3°C/0.54℉ and humidity fluctuation ±5% and that embraced in UVC air ventilation bacteriostatic environment which ensures food storage and preservation safety, achieved 2 to 3-weeks longer shelf life.

-

Shorter IFP Chilling process time than freezing does.

King Son Convertible IFP Sub Chiller Application in Processing, Storage and Quality of Cook-Chill or Cook-Freeze Foods

-

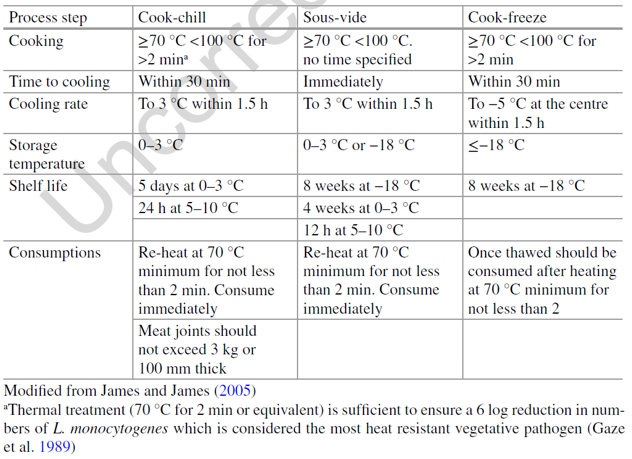

The cook-chill system is a preservation technology where food is fully cooked at usually <100°C/212.0℉ and then food is subsequently chilled rapidly and stored under controlled conditions where the final core temperature is maintained above the freezing point of food, or at 0°C/32.00℉ to 3°C/37.40℉.

-

Now “IFP Chilling preservation” are being used to extend the shelf-life of cooked food by maintaining food’s storage temperature between 0°C/32.00°F and above the freezing point of food, without freezing.

-

IFP Chilling could increase the shelf-life of cook-chill food.

-

Cook-freeze foods are treated and processed the same way as cook-chill foods, but the final food product is either super-chilled (that cooled and maintained at 1°C/32.80℉ to 2°C/35.60℉ below the freezing point of food) or frozen-chilled (that frozen at a temperature of below -30°C/-22.00℉ and then thawed to 5°C/41.00℉ when needed).

-

Table 7.1 Processing requirements and shelf life of cook-chill, sous-vide and cook-freeze products

-

(Source:

-

Atef Elansari et al./Processing, Storage and Quality of Cook-Chill or Cook-Freeze Foods

-

What is cook chill? What is King Son Cook IFP chilling preservation method?

-

A food preservation method in which it is prepared and portioned, cooked, and then either chilled by commercial blast chiller to

-

3°C/37.40℉ in a central kitchen. Cook-chill preserves food for up to four days before it is reheated for eating, or

-

IFP Chilling temperature, between 0°C/32.00℉ and above IFP (initial freezing point) of food, without freezing it, and then preserving it in King Son Convertible IFP Sub Chiller for over than four days to 2-3 weeks, before it is reheated for consumption.

-

The methodology – King Son Cook IFP chilling preservation method is simple to do, all it needs is a standard blast chiller that current mechanical refrigeration techniques are well able to rapidly chill cooked food to IFP Chilling temperature, at between 0°C/32.00℉ and above IFP (initial freezing point) of food, without freezing, and then, to preserve cooked foods, transfer in King Son Convertible IFP Sub Chiller by King Son Constancy IFP Chilling Technology for longer shelf life, with IFP Chilling 2 – 3 weeks storage, before it is reheated for eating (no thawing needed).

-

What is cook freeze? What is King Son Cook IFP Superchilling preservation method?

-

A Food preservation method in which it is prepared and portioned, cooked, and then either chilled by commercial blast chiller to

-

Frozen to -20°C/-4.000℉ in a central kitchen. Cook-freeze preserves food for up to eight weeks before it is reheated for eating, or

-

Superchilling temperature, at -1.5°C/29.30°F to -2°C/28.40°F, below initial freezing point of food, with thin freezing in the outer layer of the food, and then preserved in King Son Convertible IFP Sub Chiller for 3 - 4 weeks. Has advantage of thawing more quickly, before being reheated for consumption.

-

The methodology – King Son Cook IFP Superchilling preservation method is simple to do, all it needs is a standard blast chiller that current mechanical refrigeration techniques are well able to rapidly superchill cooked food to IFP Superchilling temperature, at -1.5°C/29.30°F to -2°C/28.40°F, below initial freezing point of food, and then, to preserve cooked foods, transfer in King Son Convertible IFP Sub Chiller by King Son Constancy IFP Superchilling Technology for longer shelf life, with IFP Superchilling 3 – 4 weeks storage. As stated, has advantage of thawing more quickly, before being reheated for consumption.

-