Superchilling preservation

Case study: Superchilling preservation

Currently the commonly used preservation methods including traditional refrigeration storage, crush ice and freezing

- Traditional refrigeration storage, due to refrigeration temperature 2°C/35.6℉ to 6°C/42.80°F and high temperature fluctuations ±5℃/9℉ easily cause food spoilage and shorten the shelf life of food, in which too much low humidity also leads to serious drying loss.

- Crush ice preservation is easily to produce too much bacteria and increase transport weight of foods.

- Freezing preservation has a longer shelf life but heavy damage to the tissue cells of food.

The next novel generation of food preservation method is to preserve food above or just below initial freezing point temperature. King Son Convertible IFP Superchiller is incorporated with A7 Intelligent Foodtech Controller and designed in Constant Temperature and humidity multiple points monitor, and servo control technology commercializes Constancy IFP Superchilling preservation technology.

Preserves food just below initial freezing point is also called Superchilling. Superchilling is a conservation method for foods where some of the water about 10%~30% in the food product is frozen, the product is then held and preserved at a constant temperature between -1.5°C/29.30°F to -2°C/28.40°F that extends shelf life to 2-3 weeks longer than Traditional refrigeration storage, better quality and energy saving than crush ice and freezing.

The purpose of this experiment is to use King Son Convertible IFP Superchiller conducting Superchilling effects on food preservation. The samples used in this experiment is salmon to test what and how King Son Convertible IFP Superchiller can perform superchilling effects on food preservation.

Test equipment & material

King Son Convertible IFP Superchiller, SANYO Freezer, LG Refrigerator, ALWAYS Food Vacuum Sealer, PK Electronic Scale, Norway fresh salmon (purchased from Carrefour Supermarket)

Test method

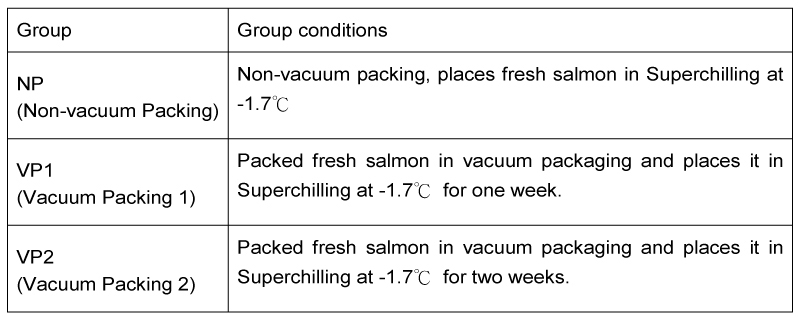

- Non-packaged weight loss % comparison between superchilled salmon group and refrigerated salmon control group

- The first part of this experiment is done for non-packaged weight loss % comparison between superchilled salmon group and refrigerated salmon control group.

- Preserved the non-packaged salmon in King Son Convertible IFP Superchiller in superchilling temperature -3℃/26.6℉/26.6℉; and stored the non-packaged salmon in traditional refrigerator. Observes and records the weight loss % of 2 groups on day 2 and day 7.

- Salmon packaged in vacuum sealer for Longer superchilling preservation experiment

- The second part of this experiment is done based on salmon packaged in vacuum sealer for longer superchilling preservation test, it is mainly used to test how long King Son Convertible IFP Superchiller can preserve vacuum packaged salmon. The measured initial freezing point for salmon used in this experiment test is between -1.4℃/29.48℉ and -1.5℃/29.30℉, therefore, the proposed initial freezing point setup in King Son Convertible IFP Superchiller is -1.7℃/28.94℉.

Purchased Norway fresh salmons from Taiwan’s local supermarket and separately packed them to 3 testing groups.

- After weighted each group and then preserved them in King Son Convertible IFP Superchiller and refrigerator respectively, and observes their appearance change and records weight change on day 0, 2, 7 and 14.

Experiment results

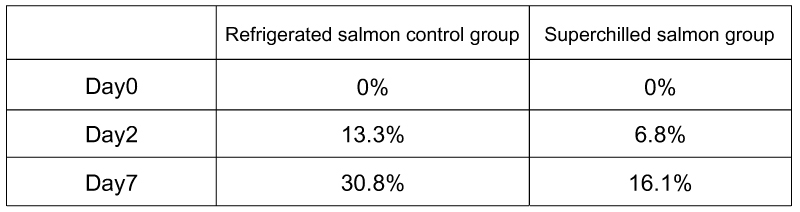

- Non-packaged weight loss % comparison results between superchilled salmon group and refrigerated salmon control group

Non-packaged salmon weight loss % comparison between -3℃/26.6℉ superchilling preservation and refrigerated storage

- Salmon packaged in vacuum sealer for longer superchilling preservation experiment resultso This experiment results indicated that, without any packing, the preservation and storage whatever in day 2 or day 7, the weight loss by Superchilling is significantly lower than by refrigeration.

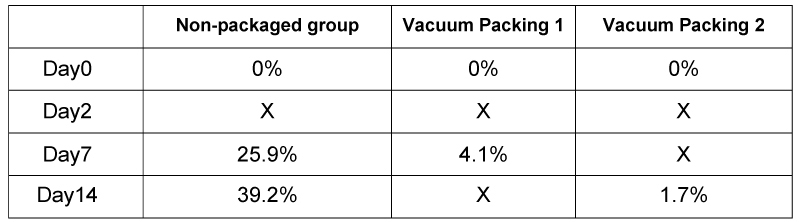

- Salmon weight loss % comparison between -1.7℃/28.94℉ superchilling preservation (VP1, VP2 group) and Non-packaged NP group

- Shown as test results table, the weight loss in preservation by Superchilling is significantly low then by refrigeration. However, it is still necessary to package food well when for longer preservation and storage. The Pictures as below shown the appearances change in each stage (Day 0, 2, 7, 14)

- The Picture in upper left shown is Norway fresh salmon; and the picture in upper right shown is salmon fillet after being vacuum packaged.

- The picture in upper left shown is vacuum packaged salmon preserved in Superchilling for 7 days; and the pictures in upper right is “Control group”, without packaging, preserved in refrigeration for 7 days. It is observed that the appearance, color and texture on vacuum packaged salmon are preserved by Superchilling very well, however, the appearance, color and texture on “Control group “that preserved in refrigeration is significantly lost glossy and flesh color dull.

- The pictures below shown is the day 14 unpacking observation.

- This picture evidenced that Superchilling can preserves the quality of vacuum packaged salmon very well, benefits commercial profit from glossy appearance.

- Conclusions

- King Son Convertible IFP Superchiller provide above 85% constant high humidity, that even can preserve food without package in Superchilling, its weight loss is still much lower than refrigeration storage. However, it is still necessary to package food when for longer superchilling preservation. King Son Convertible IFP Superchiller can preserve food by Superchilling very well, benefits commercial profit from glossy appearance and color. King Son Convertible IFP Superchiller provides Superchilling process, the best way for short term and mid-term (2-3 weeks) preservation, with advantages such as lower weight loss, glossy appearance and color, longer shelf life, shorter thawing time and energy saving.