Constancy IFP Chilling Technology

What is Initial Freezing Point (IFP) and Constancy IFP Chilling Technology?

What is Initial Freezing Point (IFP)?

-

The temperature at which a liquid freezes or becomes solid: the freezing point of water is 0°C/32.00°F.

-

Freezing point is the temperature in at any fixed pressure at which the liquid and solid phases of a substance of specified composition is in equilibrium

-

Foods and beverages do not freeze completely at a single temperature, but rather over a range of temperatures between 0°C/32.00°F and Initial Freezing Point (IFP). In fact, foods high in sugar content or packed in high syrup concentrations may never be completely frozen, even at typical frozen food storage temperatures. Thus, there is not a distinct freezing point for foods and beverages, but an initial freezing point at which crystallization begins.

-

The initial freezing point of a food or beverage is important not only for determining the food’s proper storage conditions, but also for calculating thermos physical properties. During storage of fresh fruits and vegetables, for example, the commodity temperature must be kept above its initial freezing point to avoid freezing damage. In addition, because there are drastic changes in the thermos physical properties of foods as they freeze, a food’s initial freezing point must be known to model its thermos physical properties accurately.

-

The initial freezing points of most foods are between -5°C/23.00℉ to -2.8℃/26.96℉.

What is King Son Constancy IFP Chilling Technology? What and how to commercialize Initial Freezing Point (IFP) for food preservation?

King Son Convertible IFP Food-Tech Chamber product family series is a new refrigeration and food preservation solution for the modern AIoT era. It is incorporated with A7 Intelligent Foodtech Controller and designed with Constant Temperature and Humidity Multiple Points Monitoring and Servo Control Technology, Cascade Refrigeration Technology to research, develop and perform 3 novel next generation refrigeration technologies –

-

King Son Constancy Precision Refrigeration Technology, between 0°C/32.00°F and 6°C/42.8°F

-

King Son Constancy IFP Chilling Technology, between 0°C/32.00°F and above Initial Freezing Point (IFP) of food

-

King Son Constancy IFP Superchilling Technology, -5°C/23.00℉ to -2°C/28.40℉, below Initial Freezing Point of food

that preserves and processes food in uniform conditions and environments, with temperature fluctuations ±0.3°C/0.54°F and humidity fluctuations ±5%.

King Son Convertible IFP Food-Tech Chamber product family series is an AIoT machine which incorpoarates King Son Real-Time Cloud-Based AIoT Operation Tracking and Monitoring APP System and Platform for remote distance servicing and collaboration – thus helping build new partnership opportunities through AIoT ecosystem.

What is IFP Chilling

-

The IFP Chilling refers to the temperature range between 0°C/32.00°F to the initial freezing point (IFP) of organism, which can be used to preserve and store agricultural, aquatic and meat products, etc. The initial freezing points of most foods are between - 0.5°C/ 31.10°F and – 2.8°C/26.96°F. IFP Chilling that can preserves food freshness, it is an eye catching technology, the third type fresh food preservation technology after refrigeration and freezing.

-

The IFP Chilling is a low temperature preservation method, a non-frozen storage and preservation technology. The IFP Chilling technology that preserves the fresh food in IFP Chilling temperate range between 0°C/32.00°F and above initial freezing point of food, without icing/freezing, in which the food is always in a state of non-freezing, that avoids the tissue structure damage and drip loss of fresh food due to freezing and preserve the food in fresh state. The IFP Chilling technology retains the advantages of traditional refrigeration and freeze storage, and overcomes the deficiencies of both methods, and plays an important role in preserving the original state, flavor and taste of the food.

|

Methods

|

IFP Chilling

|

Refrigeration

|

Freeze

|

|

Temperature regime

|

The temperature regime is between 0°C/32.00°F to the initial freezing point (IFP) of organism.

|

The temperature regime is between 0°C/32.00°F and 10°C/50.00°F.

|

The temperature regime is below - 18 ° C/-0.4000°F.

|

|

Storage duration

|

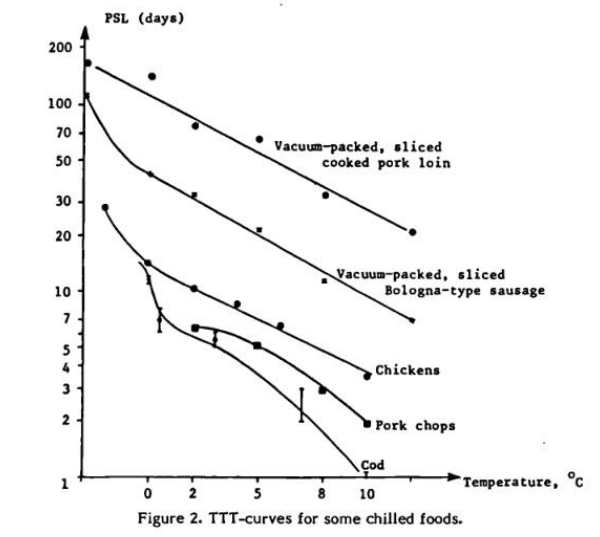

The IFP Chilling can increase fresh foods preservation time between 2 to 10 times, when it compared with traditional refrigeration storage, and the organism can be preserved for longer time.

|

The shelf life of fresh foods in refrigeration storage is about 7 days, and refrigeration is not capable for live organism preservation.

|

Freeze can storage frozen food for long time, however, freeze causes biological cell necrosis (damage).

|

|

Quality difference

|

Preserve fresh foods by IFP Chilling technology for more delicious, nutrition increase and reduce harmful microorganisms.

The IFP Chilling technique has the advantages of neither destroying the cell membrane nor losing the composition components in fresh food. |

The flavor of food is reduced due to the increase of the refrigerating time, and the harmful microorganisms gradually increase that cause food decay.

|

Freeze destroy fresh foods biological cells, and nutrient loss after thawing, and the flavor is reduced most.

|

The Principle of IFP Chilling

-

When fresh food preserved in IFP Chilling between 0°C/32.00°F to the initial freezing point (IFP) of food, the cells of the fresh food can maintain its living state, but the activity of various enzymes is inhibited, the respiratory activity is lowered, and the IFP Chilling inhibits the growth and reproduction of the spoilage bacteria, so that the shelf life of the fresh food is prolonged.

-

Most biological tissue’s initial freezing point is below 0 °C/32.00°F. When biological tissue is preserved above initial freezing point, the tissue cells contain many glucose, inorganic salts, soluble proteins, etc. Since various natural high molecular substances exist in a spatial network structure, therefore, the movement between water molecules is hindered substantially that produces freeze avoidance phenomenon, thus there are initial freezing point differences between the tissue cell liquid and the pure water.

-

The animal origin human foods can be preserved by IFP Chilling technology between 0°C/32.00°F to the initial freezing point (IFP) of foods that mainly because under the condition of IFP Chilling, the growth of microorganisms is effectively inhibited, and the spoilage of food caused by microorganisms is prevented; the IFP Chilling inhibits the respiratory metabolism of animal origin food cells, and effectively reduces the metabolic rate of cells; The polymer complexes such as proteins and polysaccharides in animal origin foods can exist in a three-dimensional network, which effectively hinders the movement and freezing of water molecules in cells; The nutrients substances contained in animal origin foods cells such as proteins, glucose and inorganic salt are not easily to freeze at low temperatures, which can lower the freezing point of cells to below 0 °C/32.00°F, which is also lower temperature than the freezing point of pure water.

The Mechanism of IFP Chilling

-

Fresh food is a biological activity organism, after chilling process in IFP Chilling conditions, biological tissues of fresh food will automatically secrete inorganic salts, soluble proteins, etc. to maintain its living state of tissue cells, this process is biologically called "organism defense response ".

-

When the IFP Chilling temperature is near the initial freezing point of fresh food, the preservation of fresh food reaches a hibernation condition, in which the product of fresh food is stored in a "dormant" state, that the tissue cells of fresh food have the lowest metabolic rate and consume the least energy, so that the fresh food can be effectively stored and preserved for longer time.

-

From the viewpoint of IFP Chilling technology, the preservation of fresh food is a biological live organism, after chilling process in IFP Chilling conditions, the biological tissues of fresh food will automatically secrete an antifreeze substance containing glucose, protein, alcohol, etc. to maintain its living state of tissue cells, this process is biologically called "organism defense response ".

-

When the IFP Chilling temperature is near the initial freezing point of fresh food, the preservation of fresh food reaches a hibernation condition, in which the product of fresh food is stored in a "dormant" state, that the tissue cells of fresh food have the lowest metabolic rate and consume the least energy, so that the fresh food can be effectively stored and preserved for longer time.

-

When the temperature drops to near initial freezing point (IFP) temperature of the animal and plant, in order to prevent freezing to death, animals and plants continuously secrete a large amount of antifreeze liquids from the body to lower the freezing point. The main composition components of this antifreeze liquids are glucose, amino acids, aspartic acid, etc. These ingredients are actually the ingredients that increase the flavor of the IFP Chilling foods. The foods processed and produced by this mechanism are called IFP Chilling foods.

-

In order to convert the nutrients, such as amino acids produced by the organism's defense response, to maximum contents, that cooling induction must be performed.

-

The lower the initial freezing point, the higher the concentration of the cell liquid solution, that is, the lower the preservation temperature, the more unfrozen substances such as glucose, protein, alcohol, etc. secreted by the living organism, which can obviously improve the taste and quality of the food. This requires that the temperature of IFP Chilling must be precisely controlled to perform the most optimal temperature distribution uniformity and control the temperature fluctuations in the equipment. The allowable temperature fluctuation ranges of IFP Chilling is ±0.3 °C/±0.54°F. Specifically, in the process of food IFP Chilling preservation, what and how to construct a controllable low temperature environment, where is close to the initial freezing point of food, uniform temperature distribution, and limited temperature variation are the key factor in preserving food quality.

The IFP Chilling Effect

-

The temperature adaptability, acclimation and tolerance of food in IFP Chilling temperature range, between 0°C/32.00°F and above the initial freezing point (IFP) of food (organism) is called the IFP Chilling Effect. In the vicinity of initial freezing point temperature of food, in order to prevent the formation of ice crystals, animals and plants continuously secrete a large amount of antifreeze liquids from the body to lower the initial freezing point of organism. The main composition components of the antifreeze liquids are glucose, amino acids, aspartic acid, etc. The IFP Chilling temperature can inhibit microbial growth.

-

In IFP Chilling temperature conditions, water molecules are arranged in an orderly state, and the free water content available for microbial use is reduced. The high, low degree of initial freezing point and the strength of the antifreeze resistance of the food tissue directly affect the effect of IFP Chilling storage. In order to resist cold, the cell membrane lipids of food must be prevented from solidifying at a low temperature to maintain normal fluidity. Unsaturated fatty acids are easily oxidized by free radicals. In normal physiological conditions, excess free radicals will be scavenged by superoxide dismutase, peroxidase and non-enzymatic substances, that will maintain a relative balance, so that the cell membrane of food will not be destroyed.

-

The cold-resistance response of plants is characterized by better water holding capacity and high soluble protein contents. When the plant is subjected to low temperature stress, the cells increase the content of free amino acids and carbohydrates, and the concentration of the cell liquids increases to protect the cells. The experiment studies have found that cold-tolerant plants can induce and synthesize cold-resistant proteins rich in hydrophilic amino acids, which are thermally stable and not denatured by low temperature, so as to reduce the energy consumption in the process of induced fit with substrate.

The IFP Chilling process and preservation advantages

-

Not destroying cells of food;

-

The activity of harmful microorganisms and the activity of various enzymes in food are inhibited;

-

Maximally inhibiting respiration and prolonging the shelf life of fresh food in preservation period;

-

Significantly improving the quality of fruits and vegetables when stored and preserved in IFP Chilling conditions, which is an advantage that is not available in both refrigeration cold storage and MAP (modified atmosphere packaging) storage methods.

IFP Chilling Prospect and development trend

-

The IFP Chilling technology is a brand new storage and preservation technology after traditional refrigeration and freeze that overcomes the disadvantages of refrigeration and freeze storage, and guarantee the flavor, taste and freshness of IFP Chilling foods. However, IFP Chilling storage and preservation technology has not been widely used and application since its birth, the main reasons are because the IFP Chilling preservation requires an accuracy temperature and humidity controlled technology, and the IFP Chilling preservation method is not easily to control and manage, once the mistake is made, it will cause great economic loss. In addition, the research and development lag for IFP Chilling technology equipment also limits the development and application of this technology.

The key technologies to perform IFP Chilling technology are cooling induction and constant temperature and humidity control.

-

The key technologies for IFP Chilling technology are cooling induction and constant temperature and humidity control.

-

The cooling induction is a cooling and cooling process that simulates the "hibernation" of living organisms, which is thru and by regulating the temperature to change the intracellular tissue composition components of preserved foods, reduces the activity of tissue cells, energy consumption, and ensures the vital characteristics of living organisms.

-

In order to convert the nutrients, such as amino acids produced by the organism's defense response, to maximum contents, that cooling induction must be performed.

-

In practice, cooling induction not only reduces the temperature of the preserved food, but also ensures that the nutrient content of the food is not lost or lost less during the process. It is found that when the cooling temperature is lowered from 10 °C/50.00°F to 5 °C/41.00°F, the cooling rate has little effect on the quality of the preserved food, and when the temperature drops from 5 °C/41.00°F to the freezing point of food has a great influence on the quality of the preserved food. The effect is mainly caused by the cooling rate, therefore, the key for cooling induction is the cooling rate between 5 °C/41.00°F and the freezing point of food. In principle, the slower the cooling rate, the better the quality. The cooling induction process from 5 °C/41.00°F to initial freezing point of food is called "low temperature domestication".

-

After the food to be preserved is cooled and induced to the initial freezing point temperature, the key is to control the freezing point temperature stably. The constant temperature and humidity control that is to precisely control the freezing point temperature of the food, so as to keep the temperature close to the freezing point as much as possible, and minimize the temperature fluctuation during the control process as small as possible to reduce the composition component changes of the preserved food and to keep its fresh quality.

In order to achieve such IFP Chilling temperature environment, the construction of IFP Chilling preservation equipment must consider the two key factors.

-

Air flow field distribution uniformity

-

High precision control technology and capability

-

Most current design in traditional refrigerator and freezer rely on vapor-compression systems that are turned on or off at high and low set points, therefore, resulting in temperature fluctuations that exceed the recommended variation of ±5℃/±0.9°F.

-

-

The key technology to perform IFP Chilling technology is constant temperature and humidity control, temperature stability is extremely important for IFP Chilling preservation effect. In order to achieve constant temperature and humidity control, the construction of the IFP Chilling process equipment must take into account the distribution uniformity of the air flow field, high-precision temperature and humidity control and automatic operation, which is a challenge in IFP Chilling technology research.

-

The uneven air flow field will affect the space usage efficiency of storage capacity in the chamber, damage the quality of preserved products, and reduce the operation control accuracy. Non uniformity temperature distribution in the traditional refrigeration cabinet is the main reason produced food waste.

King Son Constancy IFP Chilling Technology is a novel generation FoodTech after traditional refrigeration and freezing to commercialize IFP Chilling for food process and preservation between 0°C/32.00°F and above Initial Freezing Point (IFP) of food in controlled constant temperature and humidity conditions, with temperature fluctuation ±0.3°C/0.54°F and humidity fluctuation ± 5%.

The temperature ranges between 0°C/32.00°F and Initial Freezing Point (IFP) of food that can be utilized for food preservation that can inhibit harmful microbes and pathogenic bacteria of proliferation, to improve taste and flavor enzymes, yeast and lactic acid bacteria activities, avoid residual hazards caused by the use of the fungicide or disinfectant to ensure food's original taste, quality, safety and value.

King Son Constancy IFP Chilling Technology commercializes the economic value of the temperature ranges between 0°C/32.00°F and above Initial Freezing Point (IFP), that performs temperature fluctuation ±0.3°C/0.54°F and humidity fluctuation ±5 % for food preservation in food industry.

The effects of King Son Constancy IFP Chilling Technology applied on the fresh food preservation mainly includes

- The Constancy IFP Chilling can inhibit respiration, delay the respiratory peak and reduce the loss of nutrients. The exhaled volume of CO2 in the Constancy IFP Chilling (-0.8℃/30.56℉) is less than that stored in normal temperature about 30% to 60%.

- The Constancy IFP Chilling won’t destroy the cells, but improve the quality of fruits and vegetables in the vicinity of freezing temperature. In order to prevent from forming ice, fruits will secrete large amounts of antifreeze (its main ingredients are glucose, amino acids, aspartic acid etc.) to reduce the freezing point, or decompose the starch into sugar. These physiological changes improve the quality of fruits and vegetables in different degrees.

- The Constancy IFP Chilling can inhibit the growth of microbial efficiently. Under the condition of Constancy IFP Chilling, water molecules in fruits or vegetables are arranged in an orderly state, which reduce the content of free water available for the microbial. In the short and mid period preservation, King Son Constancy IFP Chilling can inhibit multiplication of microorganisms, better than the frozen temperature.

- Since the Constancy IFP Chilling can inhibit chemical reaction strongly, the food quality in Constancy IFP Chilling is better than that of the normal cold storage. The Constancy IFP Chilling also can inhibit lipid oxidation, non-enzymatic and other chemical reaction. The key for the Constancy IFP Chilling preservation is to realize a hibernation state of the product. The “hibernation” process is a cooling process during which the product can reduce its activity ability and energy consumption through the self-adaption, starting from the change of components within cells, and at the same time ensuring their own living life characteristics. It is a typical phenomenon of natural adaption.

Food preservation in Constancy IFP Chilling, between 0°C/32.00°F and above Initial Freezing Point (IFP) of food, to prolong shelf life of food

Preserve fresh fruits, vegetables, meat and fish at a little below 0°C/32.00°F - but above the initial freezing point – without freezing is so called Constancy IFP Chilling, gives food maximum shelf life

King Son Constancy IFP Chilling Technology application process

-

Keep Freshness

-

Preservation

-

Aging

-

Fermentation

-

Rigor off

-

Dehydration

-

Inspissation

The experiment abstracts of fruit and vegetable preservation in Constancy IFP Chilling, between 0°C/32.00°F and above Initial Freezing Point (IFP) of food